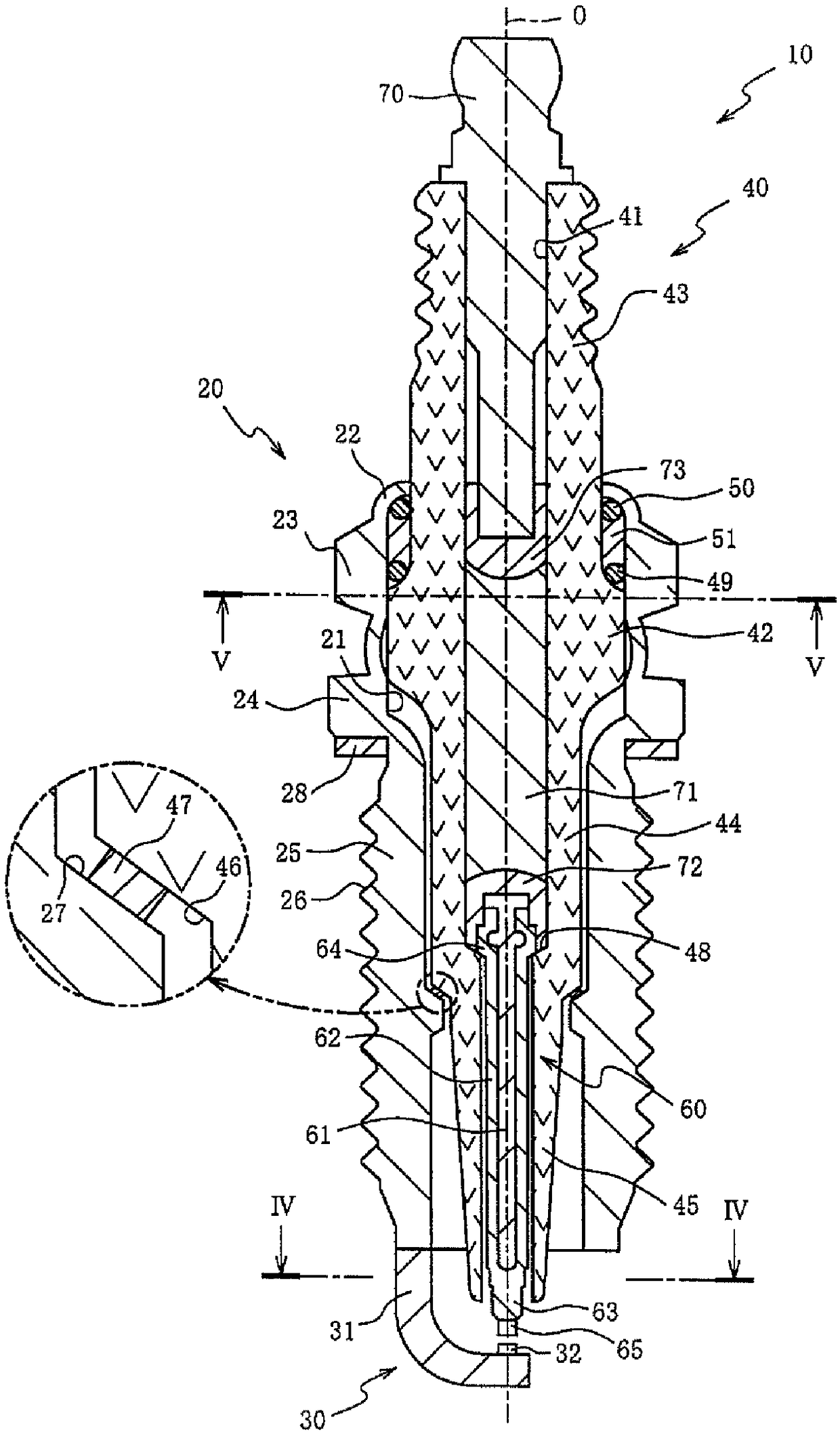

Spark plug

A technology for spark plugs and insulators, which is applied in the field of spark plugs, can solve the problems of carbon burning of insulators, etc., and achieve the effects of improving fouling resistance, simple structure, and ensuring fouling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0075] The present invention is explained in more detail by way of examples, but the present invention is not limited to the examples.

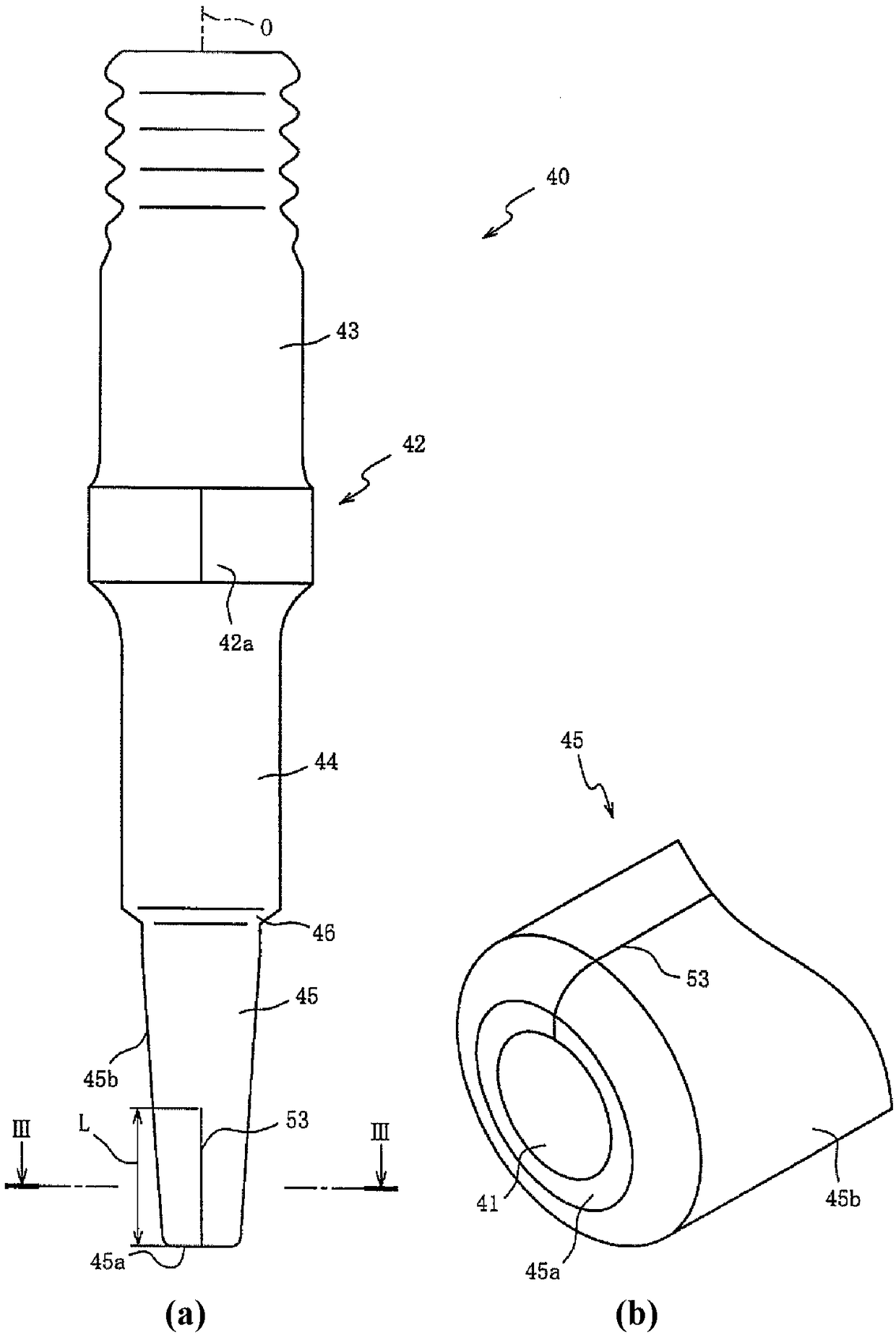

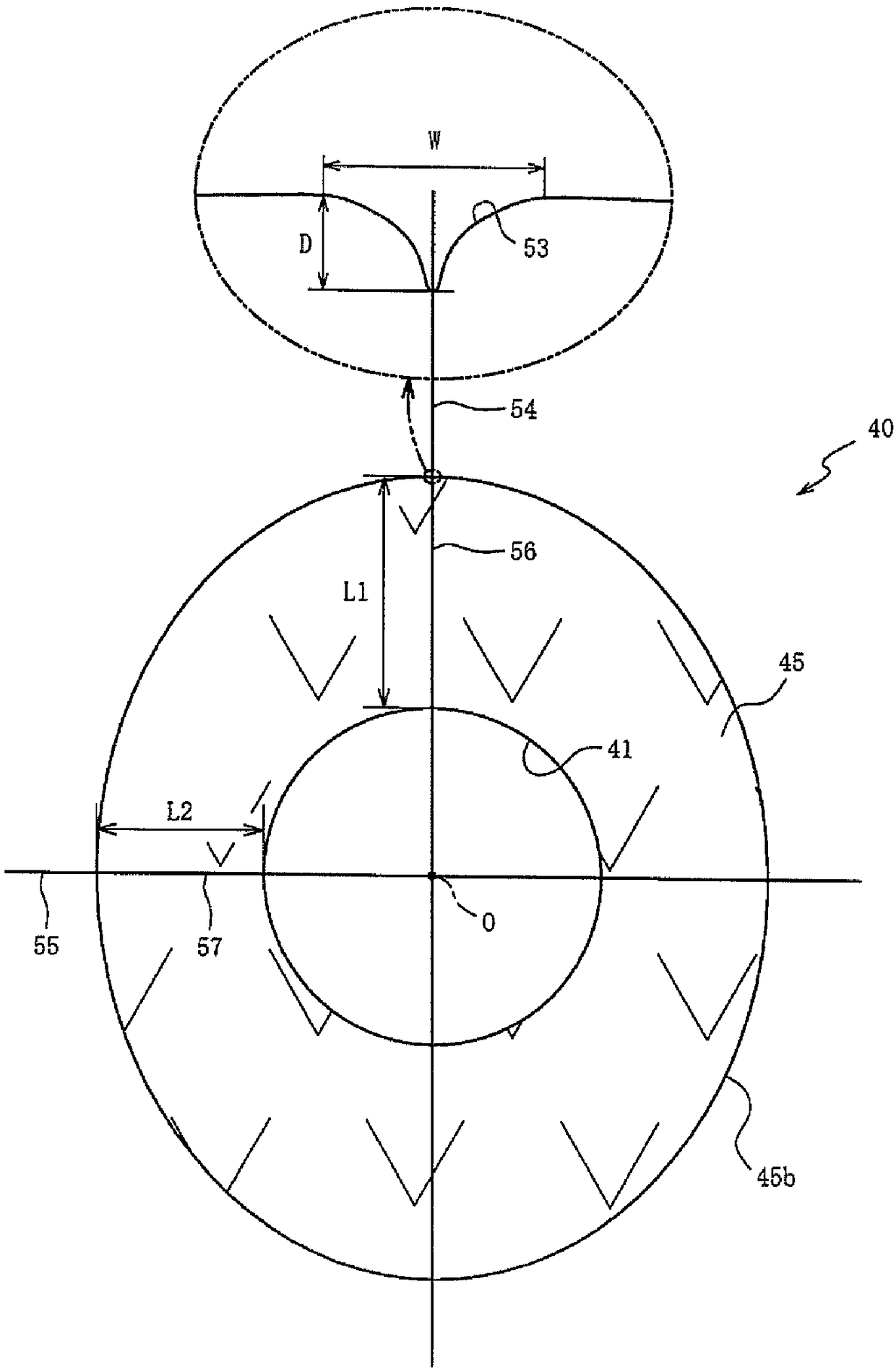

[0076] Samples 1 to 30 of the spark plug 10 incorporating various insulators 40 were produced, and the fouling properties and withstand voltage were evaluated. As shown in Table 1, in samples 1 to 30, the arithmetic mean roughness (Ra) of the outer peripheral surface 45b of the front end portion 45 of the insulator 40, the depth D of the concave portion 53, the width W of the concave portion 53, the number of the concave portion 53, the second The value (length ratio) obtained by dividing the length L2 of the region 57 by the length L1 of the first region 56 and the position (angle) of the concave portion 53 with respect to the first region 56 are different. In addition, the length L of the recessed part 53 was set to 15 mm in all the samples 1-30. In addition, in the sample in which the plurality of recesses 53 were formed, the recesses wer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com