Electrical control cabinet

A technology for electrical control cabinets and cabinets, which is applied to electrical components, electrical equipment shells/cabinets/drawers, cabinets/boxes/drawer parts, etc. Internal circuit short circuit etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

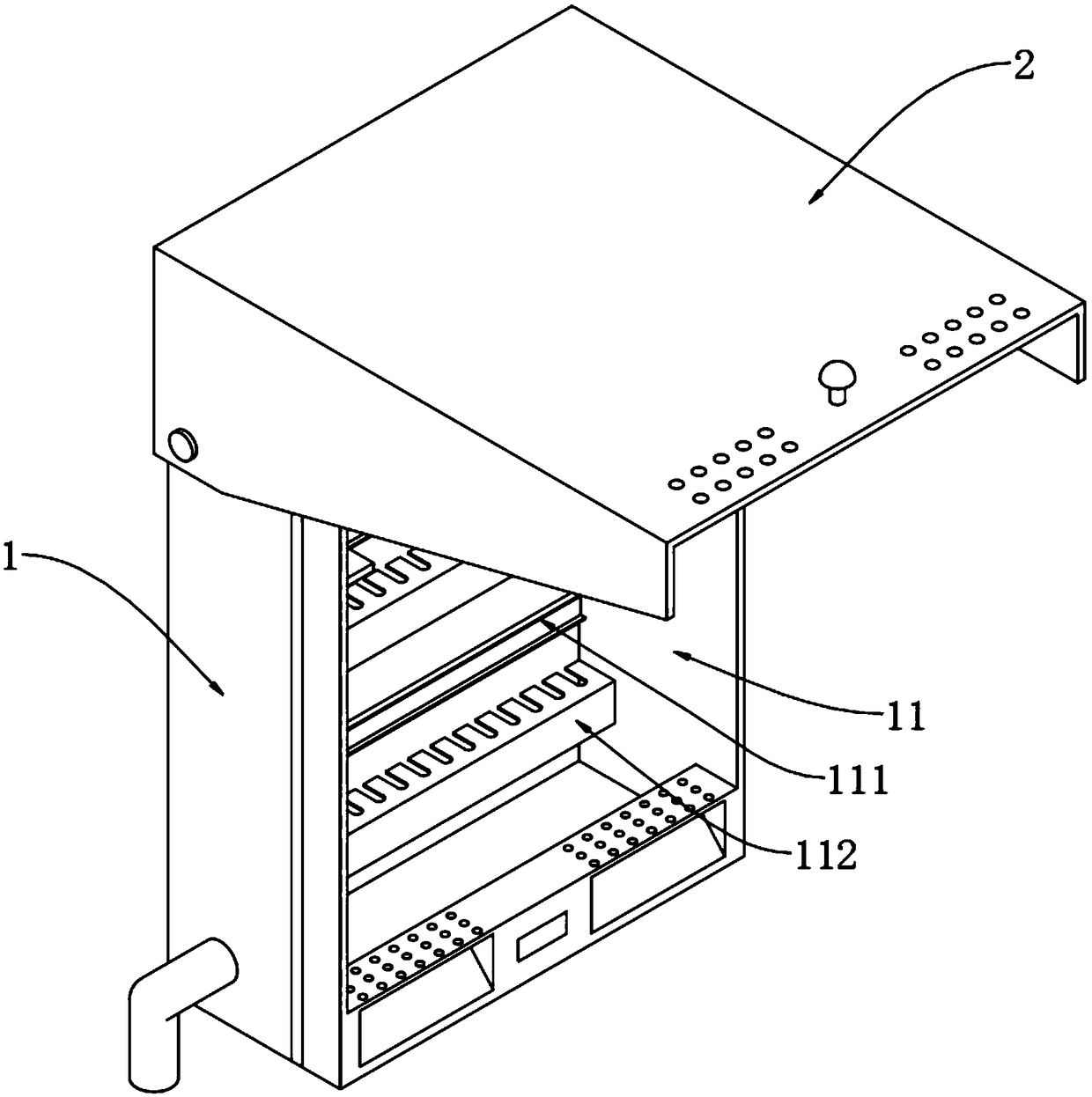

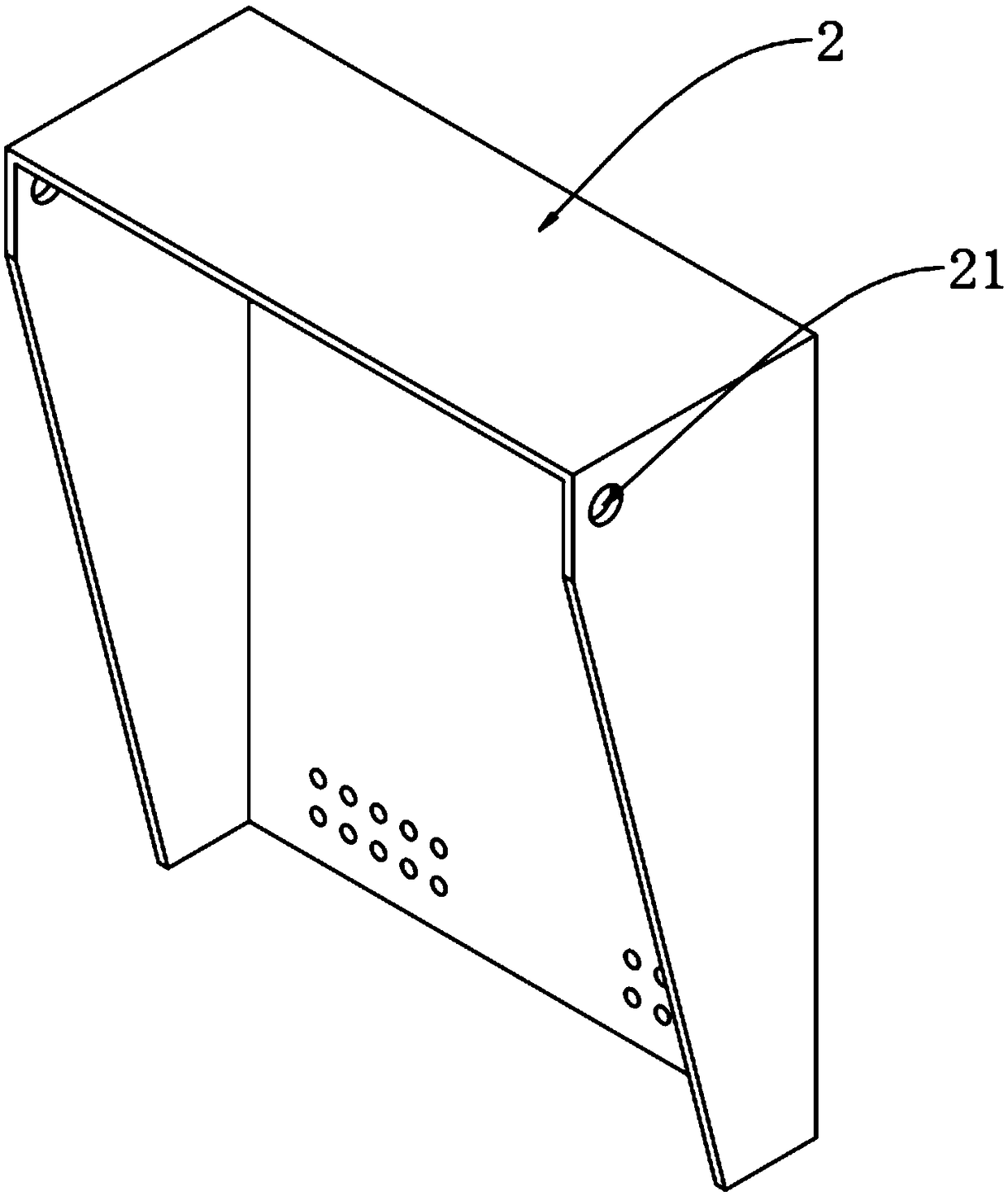

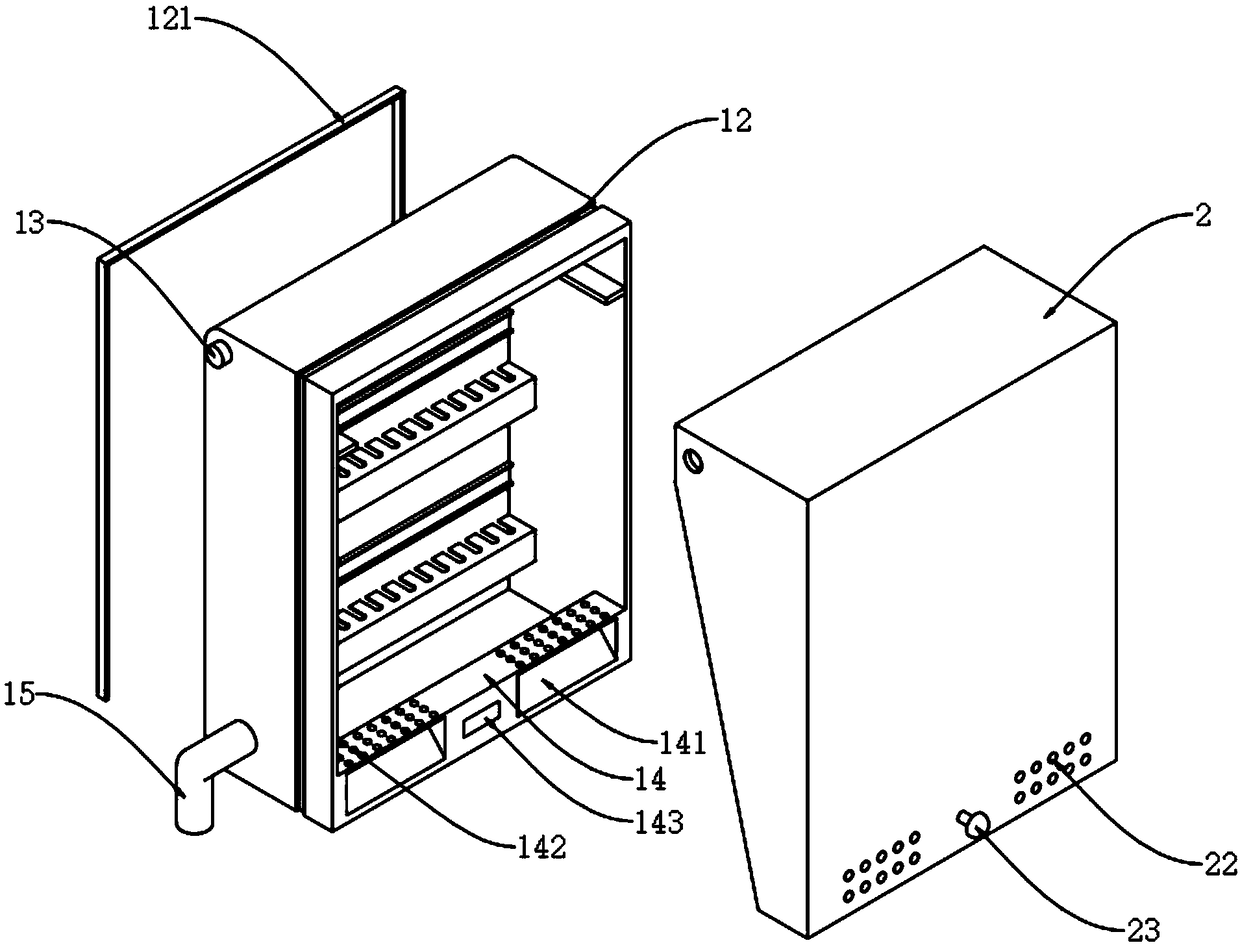

[0033] An electrical control cabinet, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, including the cabinet body 1, the cabinet body 1 is provided with a cavity 11, and the outer surface of the cabinet body 1 is provided with a long groove 12, and a sealing strip 121 is embedded in the long groove 12, and the bottom edge of the cavity 11 A bottom column 14 is provided at the bottom column 14, and a pair of symmetrically distributed inclined openings 141 are provided at the front end of the bottom column 14. Several through holes 142 connected with the inclined openings 141 are opened at the top of the bottom column 14, and the front end of the cabinet body 1 is hinged with a surface. Cover 2.

[0034] In this embodiment, a number of mounting plates 111 for installing switchgear are installed on the bottom of the cavity 11 through screws, and a cable management plate 112 for hiding connecting cables is installed under the mounting plates 111 through screws. ...

Embodiment 2

[0038] In the specific operation, since the switchgear in the electrical control cabinet is easy to catch fire when a short circuit occurs, if it is not prevented, it is very easy to cause a fire. Therefore, a C-shaped partition is tightly welded at the top of the cavity 11. Plate 16, the top of partition 16 is overlapped with storage device 3, as a kind of preferred embodiment, as Figure 5 , Image 6 and Figure 7 As shown, the storage device 3 includes a storage box 31 slidably connected to the cavity 11, a film 32 overlapped in the storage box 31, and a pressure frame 33 slidably connected to the storage box 31. The storage box 31 is a cuboid structure, and the storage box 31 There is a storage cavity 311 inside, and the bottom end of the storage cavity 311 is provided with a bottom opening 312 in a rectangular shape. Slots 313 are provided at the middle positions of the two sides.

[0039] In this embodiment, the film 32 is a PE film, and the pressure frame 33 is locat...

Embodiment 3

[0043] In the specific operation, since the various tools used by maintenance personnel are not easy to place when maintaining the switchgear in the cabinet, therefore, a placement platform 4 is provided at the bottom of the cabinet body 1. As a preferred embodiment, as Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, the placement platform 4 includes a placement box 41 and a number of sliding plates 42 installed in the placement box 41. The placement box 41 is a box structure with a hollow top, and the interior of the placement box 41 is provided with horizontal spacers 411. The rear end surface of the bar 411 and the rear end surface of the storage box 41 are provided with a chute 412, and the right front end of the storage box 41 is provided with a turntable 413, and the turntable 413 is provided with a rotary hole 4131, and a rotating shaft 414 is sleeved in the rotary hole 4131. The top of the rotating shaft 414 is tightly welded with the cabinet body 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com