Combined stator with insulating skeleton

A technology of combining stator and insulating skeleton, applied in the shape/style/structure of winding insulation, manufacturing stator/rotor body, windings, etc., can solve the problems of inconvenient production, low efficiency, damage, etc., and achieve reliable fixation and low noise. , the effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

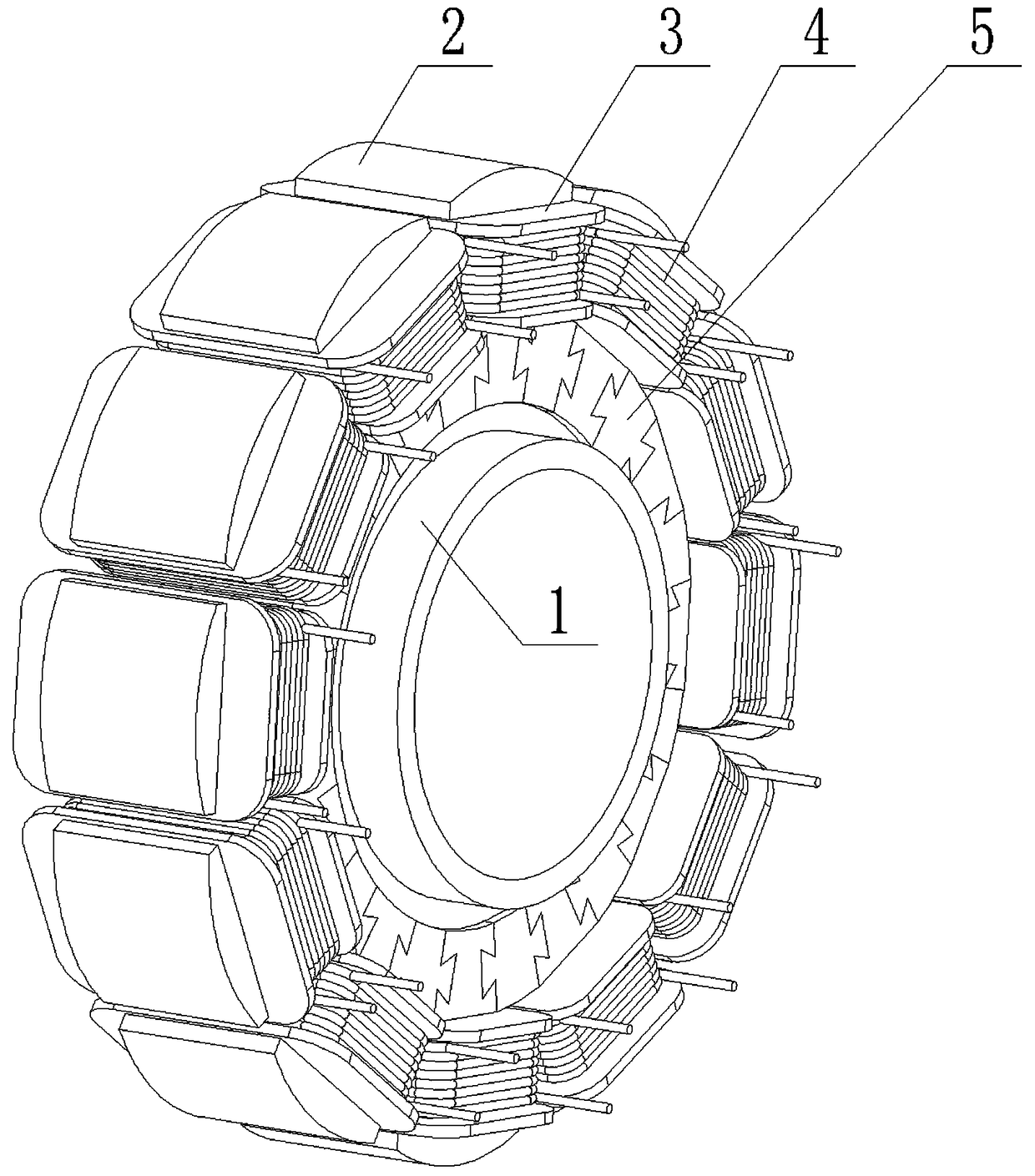

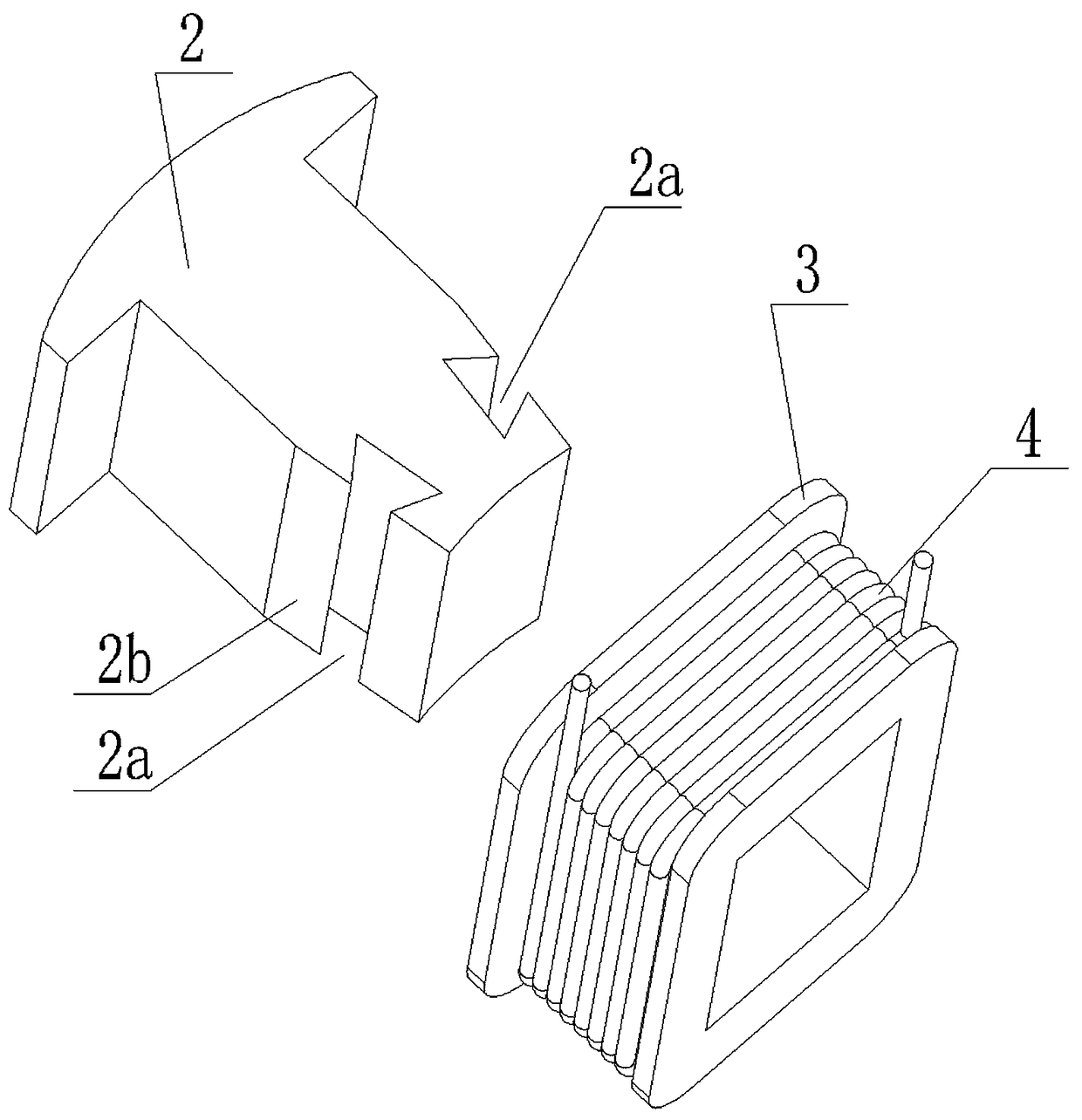

[0022] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0023] As shown in the figure, the present invention includes an expansion sleeve 1, an iron core unit 2, an insulating frame 3, a coil 4 wound on the insulating frame, and an iron core connector 5 connecting the iron core unit 2, and the iron core unit 2 is in the shape of a "T" It is made of a number of punched sheets. The two sides below the "T"-shaped iron core unit 2 are provided with tenon grooves 2a, and the two sides of the iron core connector 5 protrude from the tenon 5a. The shape of the tenon groove 2a and the tenon 5a are consistent and insulated The frame 3 is in the shape of a ring, and the coil is wound in the ring groove of the insulating frame 3, with a rectangular hole 3a in the middle, and the "T"-shaped iron core unit 2 is inserted into the square hole 3a of the insulating frame, and the "T"-shaped iron core unit 2 below The tenon groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com