Feature-guided-wave-based weld seam defect detection dedicated array type sensor time-sharing excitation system and method

A technology of characteristic guided wave and defect detection, which is applied to the generation of ultrasonic/sonic/infrasonic waves, the use of sound waves/ultrasonic/infrasonic waves to analyze solids, and the use of sound waves/ultrasonic/infrasonic waves for material analysis, etc., which can solve the problem of low detection accuracy and poor adaptability and other issues to achieve the effect of improved resolution, small dispersion, and high energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

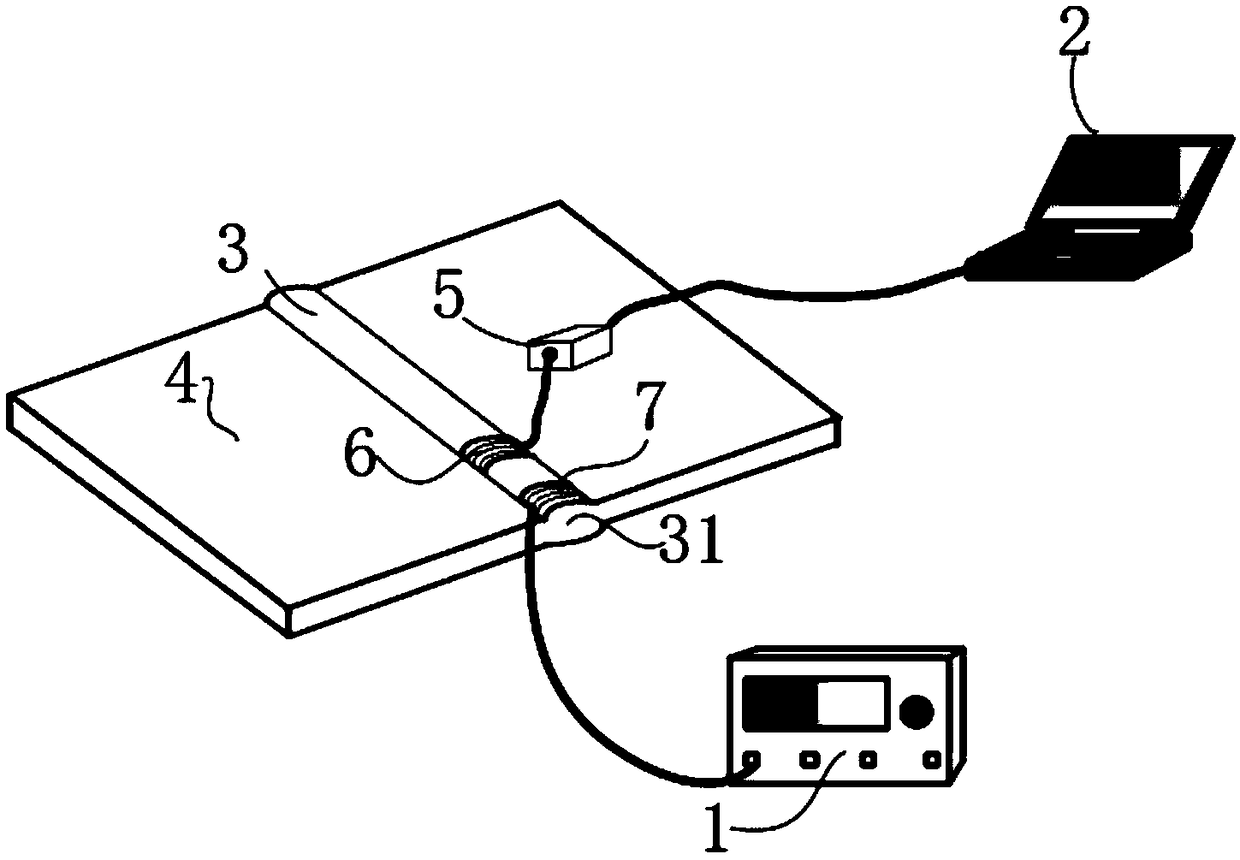

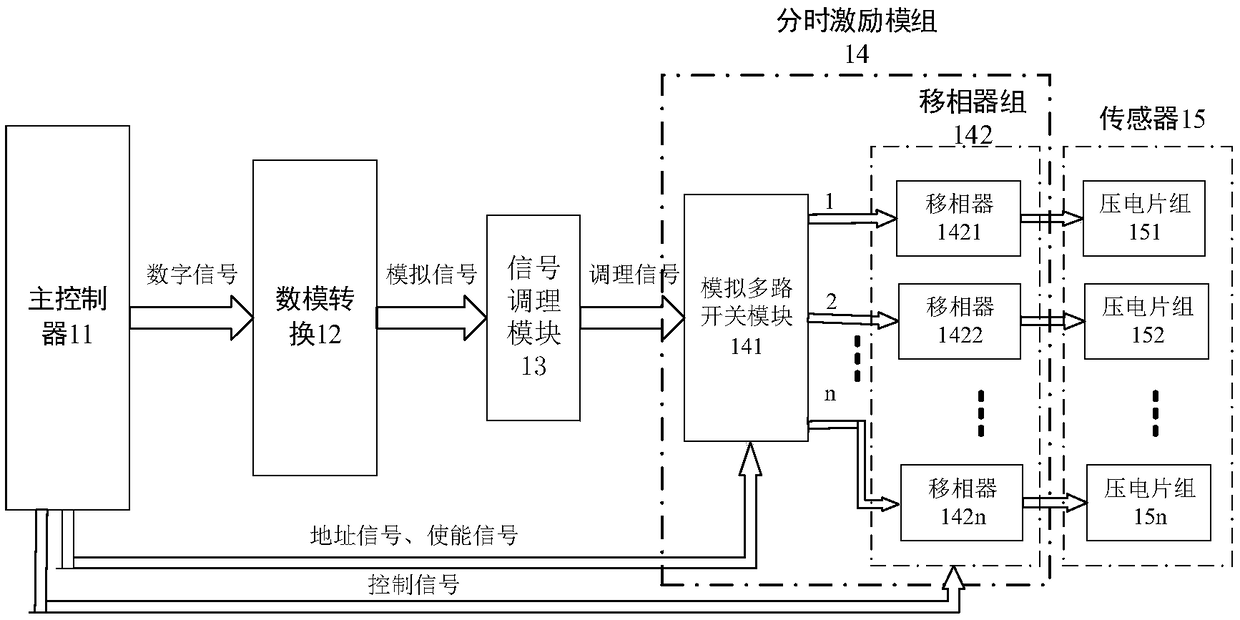

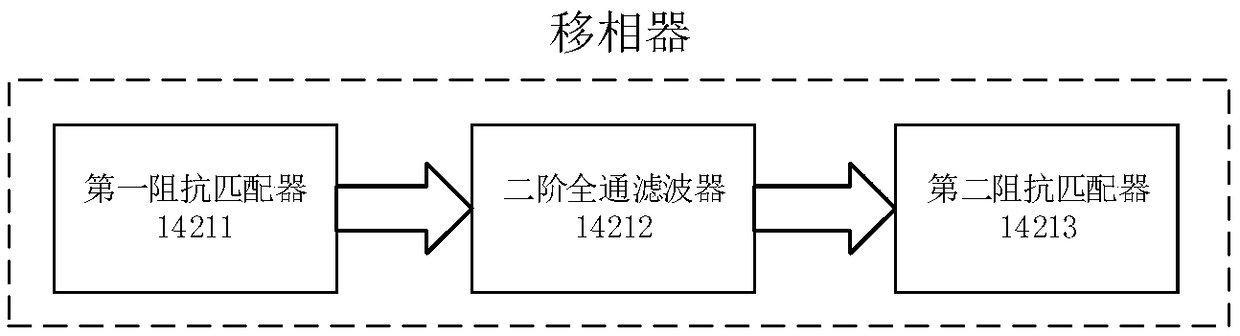

[0038] Such as figure 2 As described above, a time-sharing excitation system of a special array sensor for weld defect detection based on characteristic guided waves mainly includes: a main controller 11, a digital-to-analog converter 12, a signal conditioning module 13, a time-sharing excitation module 14 and sensor 15;

[0039] Among them, the main controller 11 is the core part of the whole system, which can generate the excitation signal of the special array sensor for the weld seam characteristic guided wave, and can provide address signals and control signals to control the operation of the whole system; the digital-to-analog converter 12 is tight After being connected to the main controller, the digital signal generated by the main controller 11 can be converted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com