A Consistency Evaluation Method for Composite Solid Propellant Aging Mechanism

A solid propellant and evaluation method technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of large limitations, inaccurate measurement, and inability to evaluate the consistency of the aging mechanism of composite solid propellants, and achieve accurate sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

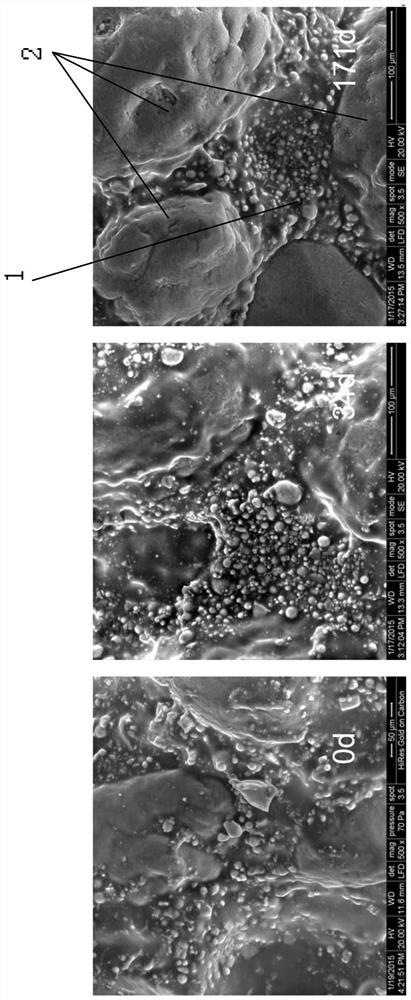

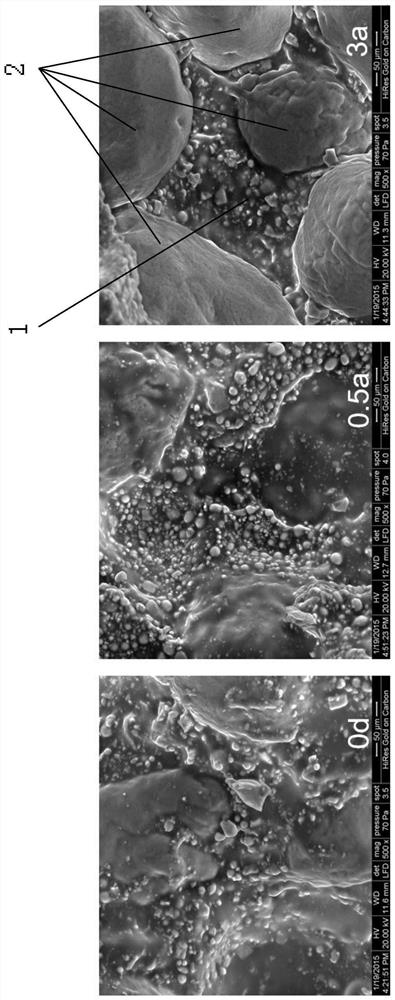

[0023] A method for evaluating the consistency of aging mechanism of a composite solid propellant (taking three-component butylated hydroxy propellant as an example), the method is carried out in the following steps:

[0024] Step 1: Carry out the natural environment accelerated test and warehouse storage test under the tropical marine atmospheric environment for the composite solid propellant samples respectively;

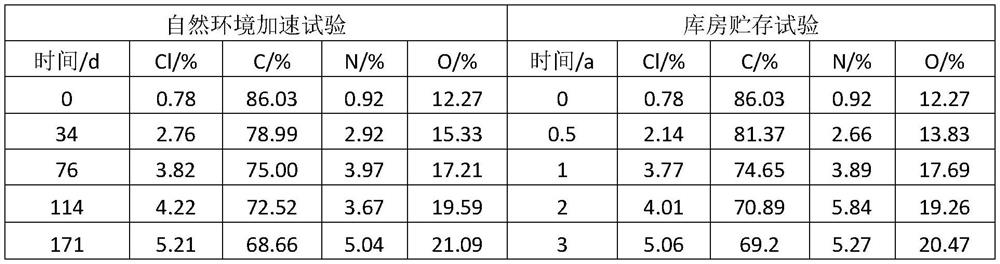

[0025] Step 2: When aging in the natural environment accelerated test for 0 days, 34 days, 76 days, 114 days and 171 days, and in the warehouse storage test for aging for 0 days, 0.5 days, 1 day, 2 days and 3 years, take out a small amount of composite solids. For the propellant test samples, the storage modulus of the samples was detected by a dynamic mechanical analyzer, the pure gel content of the samples was detected by the pure gel content test method, and the relative atomic content of the elements of the samples was detected by X-ray photoelectron spectrosco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com