TBM hoisting and translation method for deep well confined space

A closed space and hoisting technology, applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of limited construction site conditions and difficult pipeline relocation, avoiding complex construction, good promotion and application value and social Impact, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

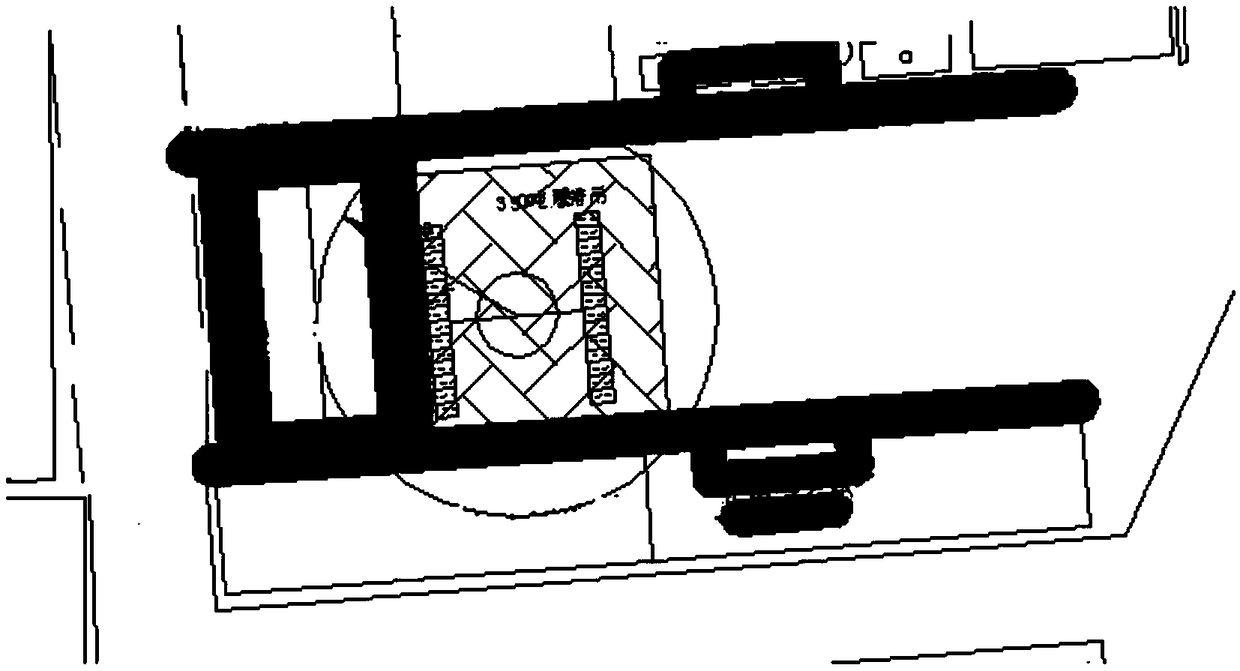

[0032] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0033] like Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a TBM hoisting and translation method in a deep well confined space. The hoisting process mainly includes the following steps:

[0034] S1, deep well hoisting

[0035] S2. Size and weight selection of main components of TBM;

[0036] S3, hoisting personnel allocation;

[0037] S4, hoisting equipment preparation;

[0038] S5. Selection of lifting equipment. The lifting equipment adopts Zoomlion QUY350 crawler crane main crane and QY160-ton truck crane to cooperate with turning over;

[0039] S6. Preparation of the construction site;

[0040] S7. Calculation of foundation bearing capacity;

[0041] S8, load rate calculation;

[0042] S9. Crane select...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com