Prefabricated beam and construction method thereof

A construction method and technology of prefabricated beams, applied in the direction of manufacturing tools, joists, girders, etc., can solve difficulties and other problems, and achieve the effect of high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

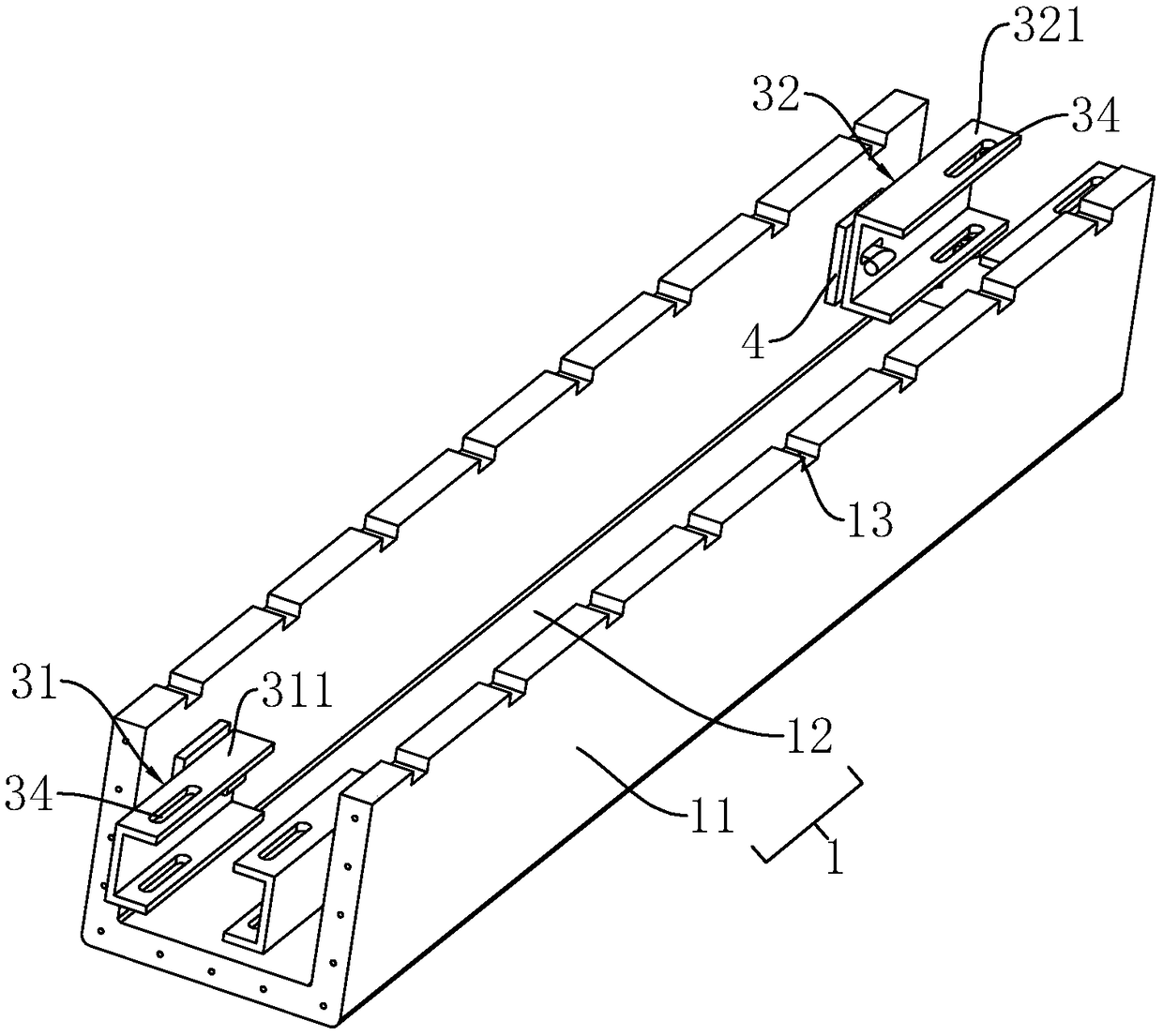

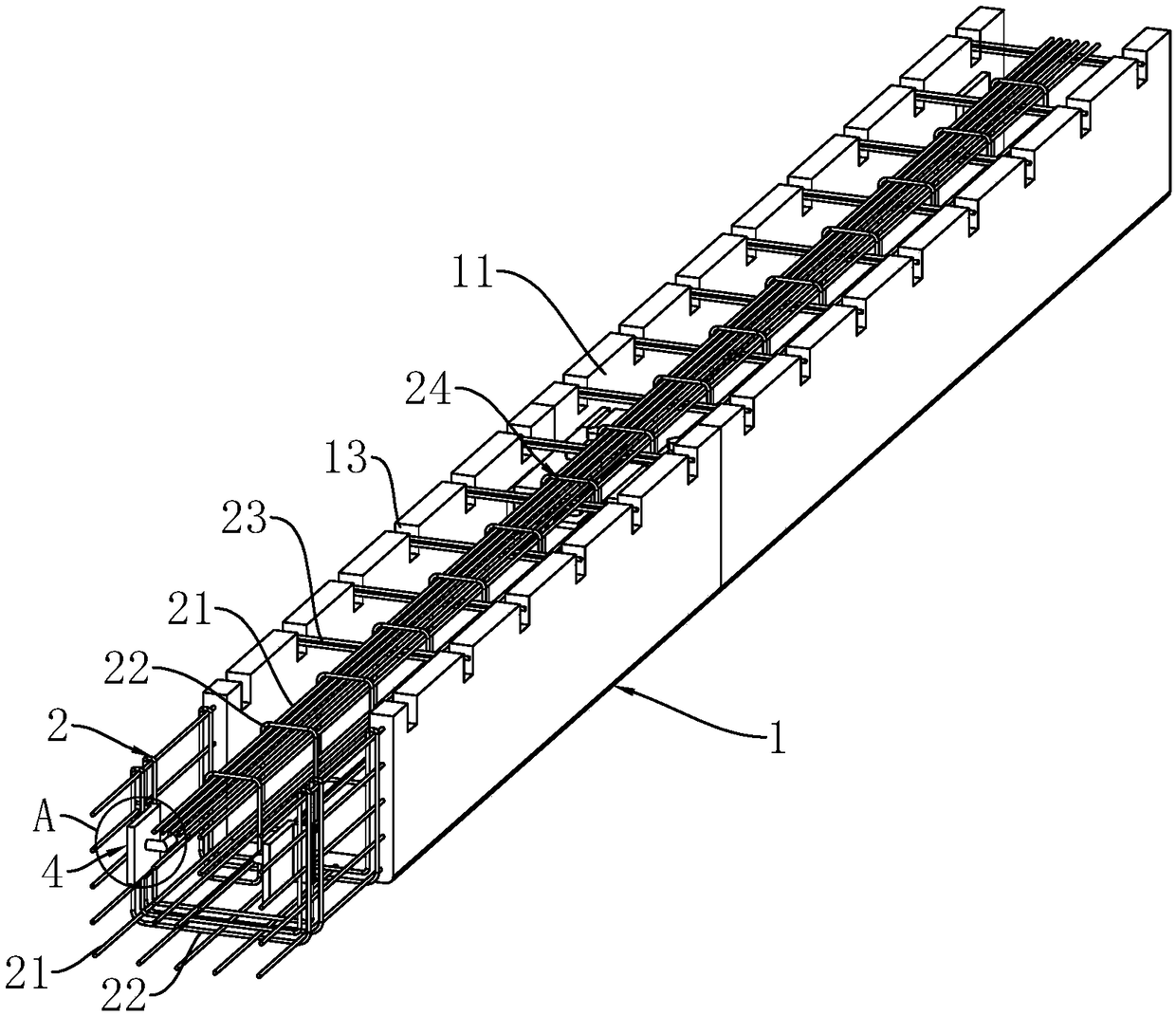

[0046] The utility model relates to a prefabricated beam, which is mainly used in building construction to bear the weight of the building and to form it. Such as figure 1 and figure 2 As shown, the prefabricated beam includes a beam body 1 with a U-shaped structure and prefabricated ribs 2 poured inside the beam body 1, so that the opening of the U-shaped beam body 1 faces upwards. At this time, when the beam body 1 is in use, place it It is transported to the location where it needs to be built, and after it is fixed in place, it is poured again inside the U-shaped structure to form a complete structural beam. In this process, the structural beam is formed by recasting the prefabricated beam as a template. On the one hand, it is lighter during transportation, and on the other hand, prefabricated ribs 2 can be added during recasting to improve its strength.

[0047] In the actual use process, the length of the beam can not be prefabricated too long in many cases, too long ...

Embodiment 2

[0051] A kind of prefabricated beam, its basic structure is the same as that of Embodiment 1, the difference lies in the setting of connecting assembly 3, beam body 1 includes side wall 11 and bottom plate 12, side wall 11 is connected through connecting assembly 3 in embodiment 1, refer to Figure 4 and Figure 5 , That is, it is connected through the first connecting plate 31 , the second connecting plate 32 , the fixing piece 33 and the connecting piece 4 on the side wall 11 . And the connection hole 121 is set on the bottom plate 12, as Figure 6 As shown, the connection holes 121 are located at both ends of the beam body 1, and the inner connection plate 35 and the outer connection plate 36 are arranged between the connection holes 121 of the adjacent beam bodies 1, and the beams are connected by the inner connection plate 35 and the outer connection plate 36. The bottom plate 12 of the body 1 is clamped, and the locking piece 37 is passed between the inner connecting pl...

Embodiment 3

[0053] A prefabricated beam such as Figure 8 and Figure 9 As shown, including the beam body 1, the beam body 1 is a U-shaped structure, and the opening is upward, and the upper hook body 14 and the lower hook body 15 are respectively arranged on both sides of the beam body 1, and the upper hook body 14 and the lower hook body 15 As the two beam bodies 1 can be connected, it can be used as the connection assembly 3 on both sides of the beam body 1, and the upper hook body 14 and the lower hook body 15 can cooperate with each other, so that the sides of the beam body 1 can be combined to make the prefabricated beam body It can be tiled to increase the bearing capacity. Embodiment 3 can be used in conjunction with Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com