A kind of preparation method of self-heating fabric

A self-heating, fabric technology, used in fiber processing, textiles and papermaking, etc., can solve the problems of solid-liquid phase change, intolerant of washing, heat generation disorder, etc., to promote blood circulation and metabolism, avoid low temperature burns, Improve the effect of tissue oxygen supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

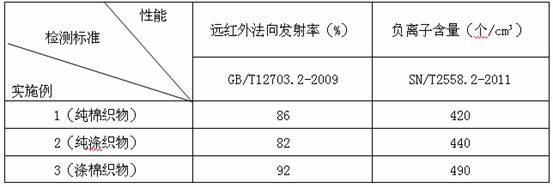

Examples

Embodiment 1

[0025] Step 1, weaving: first, sizing the warp yarn, the sizing formula is: PVA-217 is 5%, GH-22 is 3%, the sizing rate is 10%, the pH value is 6.5, and the vehicle speed is controlled at 15m / min. Then adopt air-jet loom to weave, and the speed of a vehicle is controlled at 400r / min. The specifications of the woven fabric 1 are: pure cotton fabric, weight 180g / ㎡, width 150cm, yarn count 21S*21S, density 108*58 threads / 10cm.

[0026] Step 2, pre-treatment: Walk the fabric 1 in the overflow machine for two laps to make the fabric 1 run smoothly, then pump in the dissolved lye and auxiliary agent, the lye is NaOH 10g / L, and the auxiliary agent is Add O 3g / L and ABS 1g / L flatly, the dipping bath ratio is 1:30, and then run smoothly for 3 minutes to fully contact the lye with the fabric 1, then raise the temperature to 100°C at a speed of 2°C / min, and keep it warm for 20 minutes. Then lower the temperature at a rate of 1.5°C / min, drain the liquid when it drops to 80°C, wash thorou...

Embodiment 2

[0034] Step 1, weaving: first, sizing the warp yarn, the sizing formula is: PVA-217 is 2%, GH-22 is 1%, the sizing rate is 6%, the pH value is 6.8, and the vehicle speed is controlled at 25m / min. Then adopt air-jet loom to weave, and the speed of a vehicle is controlled at 600r / min. The specifications of the woven fabric 1 are: pure polyester fabric, weight 210g / ㎡, width 150cm, yarn count 21S*21S, density 108*58 threads / 10cm.

[0035] Step 2, pre-treatment: Walk the fabric 1 twice in the overflow machine to make the fabric 1 run smoothly, then pump in the dissolved lye and auxiliary agent, the lye is NaOH 15g / L, and the auxiliary agent is Add O 5g / L and ABS 3g / L flatly, the dipping bath ratio is 1:50, and then run smoothly for 5 minutes to make the lye fully contact with the fabric 1, then raise the temperature to 100°C at a speed of 4°C / min, and keep it warm for 30 minutes. Then lower the temperature at a rate of 2°C / min, drain the liquid when it drops to 80°C, wash thorough...

Embodiment 3

[0043] Step 1, weaving: first, sizing the warp yarn, the sizing formula is: PVA-217 is 3%, GH-22 is 2%, the sizing rate is 8%, the pH value is 7.4, and the vehicle speed is controlled at 20m / min. Then the air-jet loom is used for weaving, the speed is controlled at 500r / min, and the specifications of the woven fabric 1 are: polyester-cotton fabric, 80 polyester / 20 cotton, plain weave, grammage 130g / ㎡, width 150cm, yarn count 45S*45S, Density 110*76 / 10cm.

[0044] Step 2, pre-treatment: Walk the fabric 1 twice in the overflow machine to make the fabric 1 run smoothly, then pump in the dissolved lye and auxiliary agent, the lye is NaOH 12g / L, and the auxiliary agent is Add O 5g / L and ABS 1.5g / L flatly, the dipping bath ratio is 1:50, and then run smoothly for 5 minutes to make the lye fully contact with the fabric 1, then raise the temperature to 100°C at a speed of 2.5°C / min, and keep it warm for 25 minutes , then lower the temperature at a rate of 2°C / min, drain the liquid wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com