Complete-effect low-anaphylaxis surfactant composition, and laundry detergent containing complete-effect low-anaphylaxis surfactant composition

A surfactant and composition technology, applied in the field of full-effect low-sensitivity surfactant composition and laundry detergent containing it, can solve the problems of decreased content of active substances, high cost of mild and mild raw materials, and existence of irritation, and achieve environmental protection Small pollution, low cost, no allergenic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

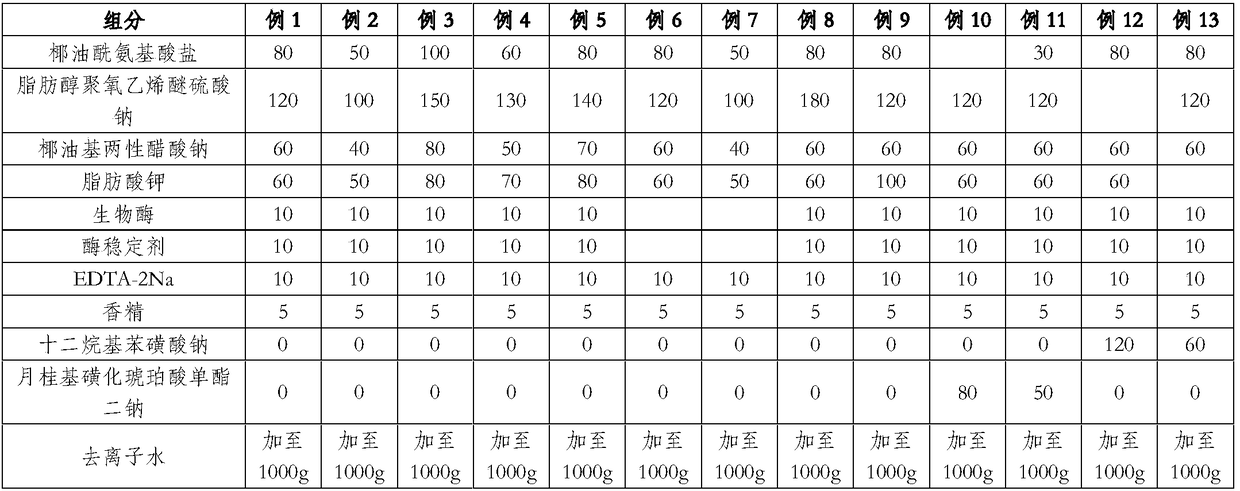

Embodiment 1

[0038] The preparation method of the laundry detergent is as follows: 80 g of potassium cocoyl glycinate, 120 g of sodium fatty alcohol polyoxyethylene ether sulfate, 60 g of sodium cocoamphoacetate, and 60 g of fatty acid potassium were added to water at 50°C. After stirring evenly, when the temperature is lowered to 30°C, add 10 grams of biological enzyme (liquid protease), 10 grams of enzyme stabilizer 4-formylphenylboronic acid, 10 grams of chelating agent EDTA-2Na, 5 grams of essence, and make up the remaining water. Stir evenly to obtain the laundry detergent.

Embodiment 2

[0040] The preparation method of the laundry detergent is as follows: 50 g of potassium cocoyl glycinate, 100 g of sodium fatty alcohol polyoxyethylene ether sulfate, 40 g of sodium cocoamphoacetate, and 50 g of fatty acid potassium were added to water at 60°C. After stirring evenly, when the temperature is lowered to 30°C, add 10 grams of biological enzyme (liquid protease), 10 grams of enzyme stabilizer 4-formylphenylboronic acid, 10 grams of chelating agent EDTA-2Na, 5 grams of essence, and make up the remaining water. Stir evenly to obtain the laundry detergent.

Embodiment 3

[0042] The preparation method of the laundry detergent is as follows: 100 g of potassium cocoyl glutamate, 150 g of sodium fatty alcohol polyoxyethylene ether sulfate, 80 g of sodium cocoamphoacetate, and 80 g of fatty acid potassium were added to water at 60°C. After stirring evenly, when the temperature is lowered to 30°C, add 10 grams of biological enzyme (liquid protease), 10 grams of enzyme stabilizer 4-formylphenylboronic acid, 10 grams of chelating agent EDTA-2Na, 5 grams of essence, and make up the remaining water. Stir evenly to obtain the laundry detergent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com