Selenium drum power end protecting cover assembling machine

A power end and assembly machine technology, applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as low efficiency and no guarantee of installation quality, achieve high installation efficiency, maintain consistency, and reduce installation troubles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

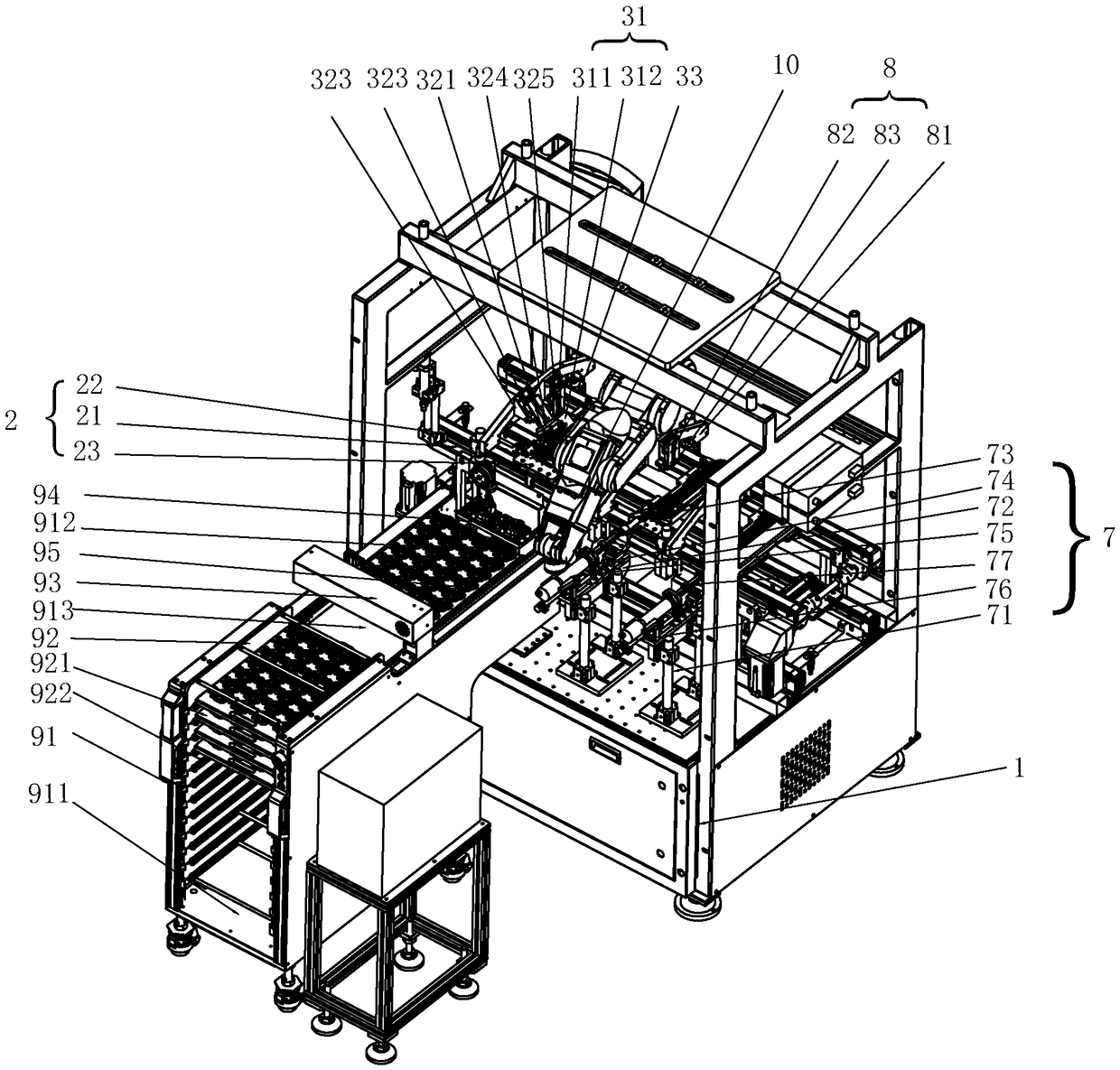

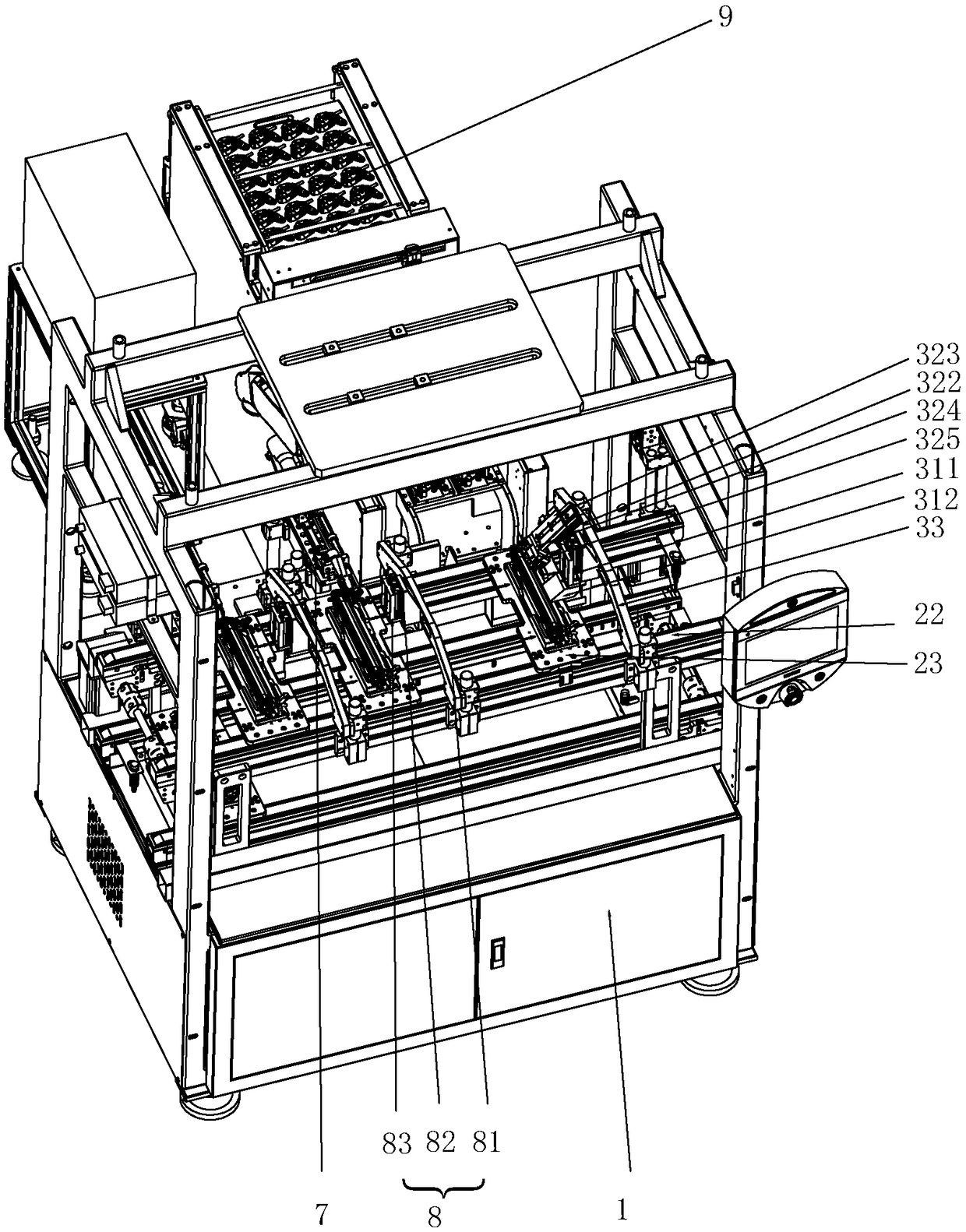

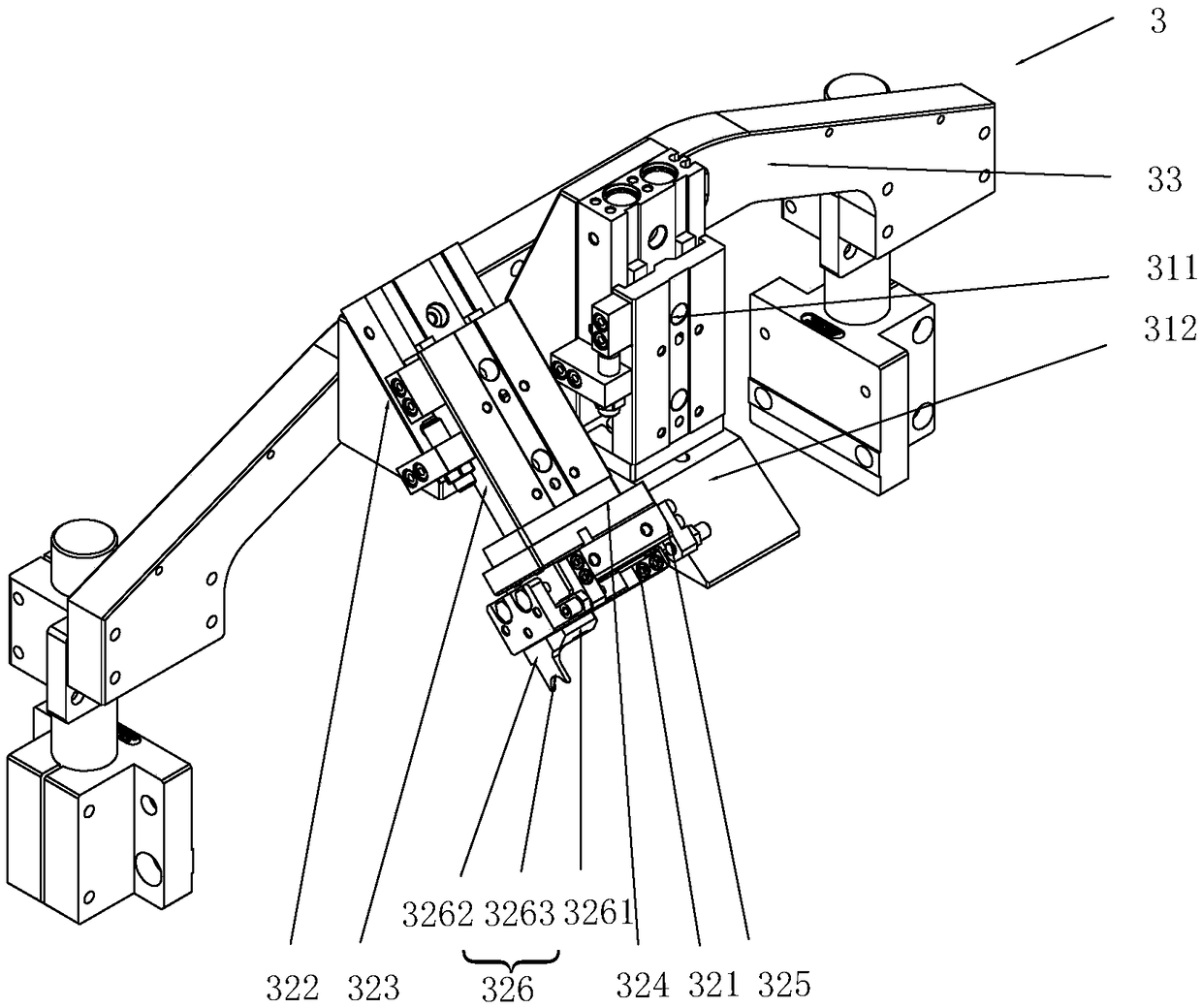

[0025] see Figure 1 to Figure 6 , a toner cartridge power end cover assembly machine of the present invention, comprising a frame 1, a conveying platform 2 for conveying the toner cartridge 4, and a manipulator 10, the conveying platform 2 is arranged on the frame 1, and the frame 1 is located at An assisting mechanism 3 is erected above the conveying platform 2, and the assisting mechanism 3 is provided with a pressing member 31 that compresses the toner cartridge 4 on the conveying platform 2. With the toggle member 32 at the upper end, the manipulator 10 can hold the protective cover 5 and install it on the power end of the toner cartridge 4 . In order to facilitate the work of the whole assembly machine, the frame 1 side is also provided with a feeding group 9 for conveying the protective cover 5, and the manipulator 10 can hold the protective cover 5 on the feeding group 9 and install it on the power end of the toner cartridge 4 , adopting the feeding group 9 for feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com