Water-sediment multistage filtration and separation device

A separation device and stage filtration technology, applied in the direction of filtration separation, separation method, filtration loop, etc., can solve the problems of inability to be directly used, slow separation rate, increase investment, etc., to improve the utilization rate of sand particles and speed up the flow rate. , reduce the effect of mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following is further described in detail through specific implementation methods:

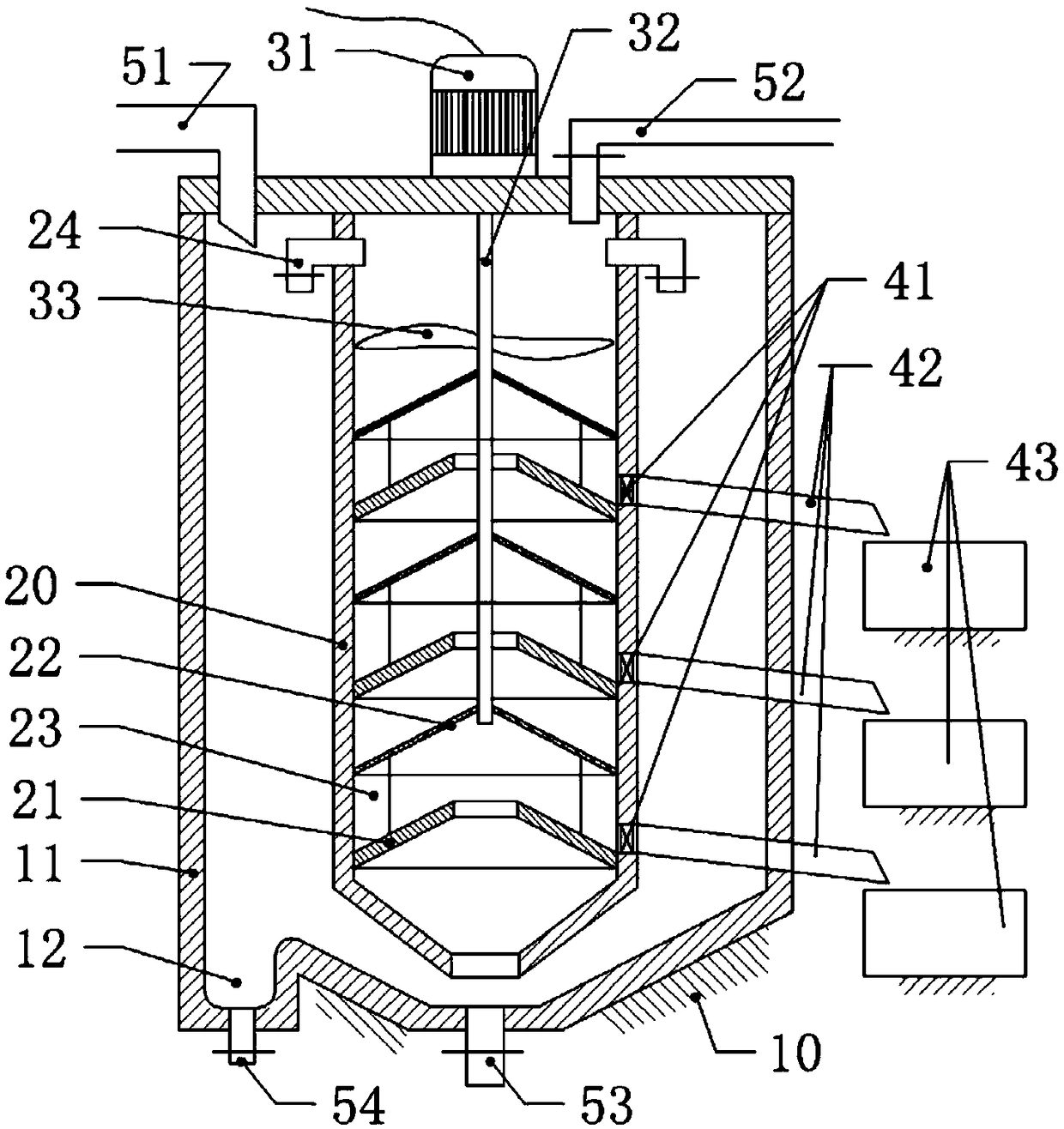

[0017] The reference signs in the accompanying drawings of the description include: frame road 10, tank body 11, sedimentation tank 12, filter barrel 20, collecting plate 21, filter screen 22, scraper 23, circulating water outlet 24, motor 31, transmission shaft 32, Impeller 33, discharge valve 41, discharge pipe 42, collection barrel 43, water inlet 51, water outlet 52, sewage outlet one 53, sewage outlet two 54.

[0018] The embodiment is basically as attached figure 1 Shown:

[0019] The multi-stage filtration and separation device for water quality sediment comprises a bracket 10, a tank body 11, a filter bucket 20, a motor 31, a discharge pipe 42 and a collection bucket 43, the tank body 11 is vertically arranged on the frame 10, and the bottom of the tank body 11 is arranged It is an inverted cone shape, the top of the tank body 11 is provided with a water inlet 51 and a wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com