Wire routing structure and busbar module

A bus bar module and bus bar technology, applied in structural parts, cell structure combinations, circuits, etc., can solve problems such as jumping out of detection lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

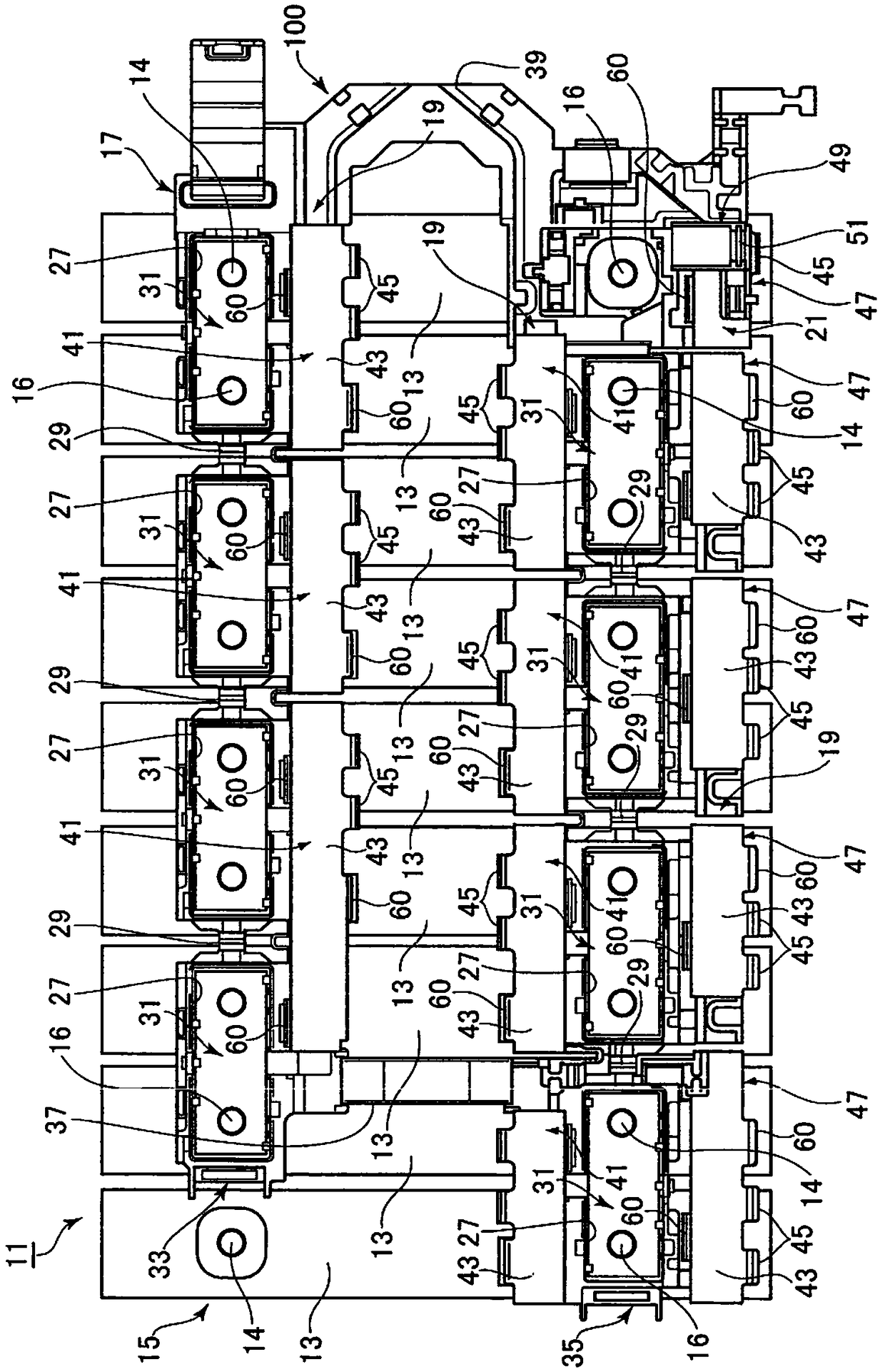

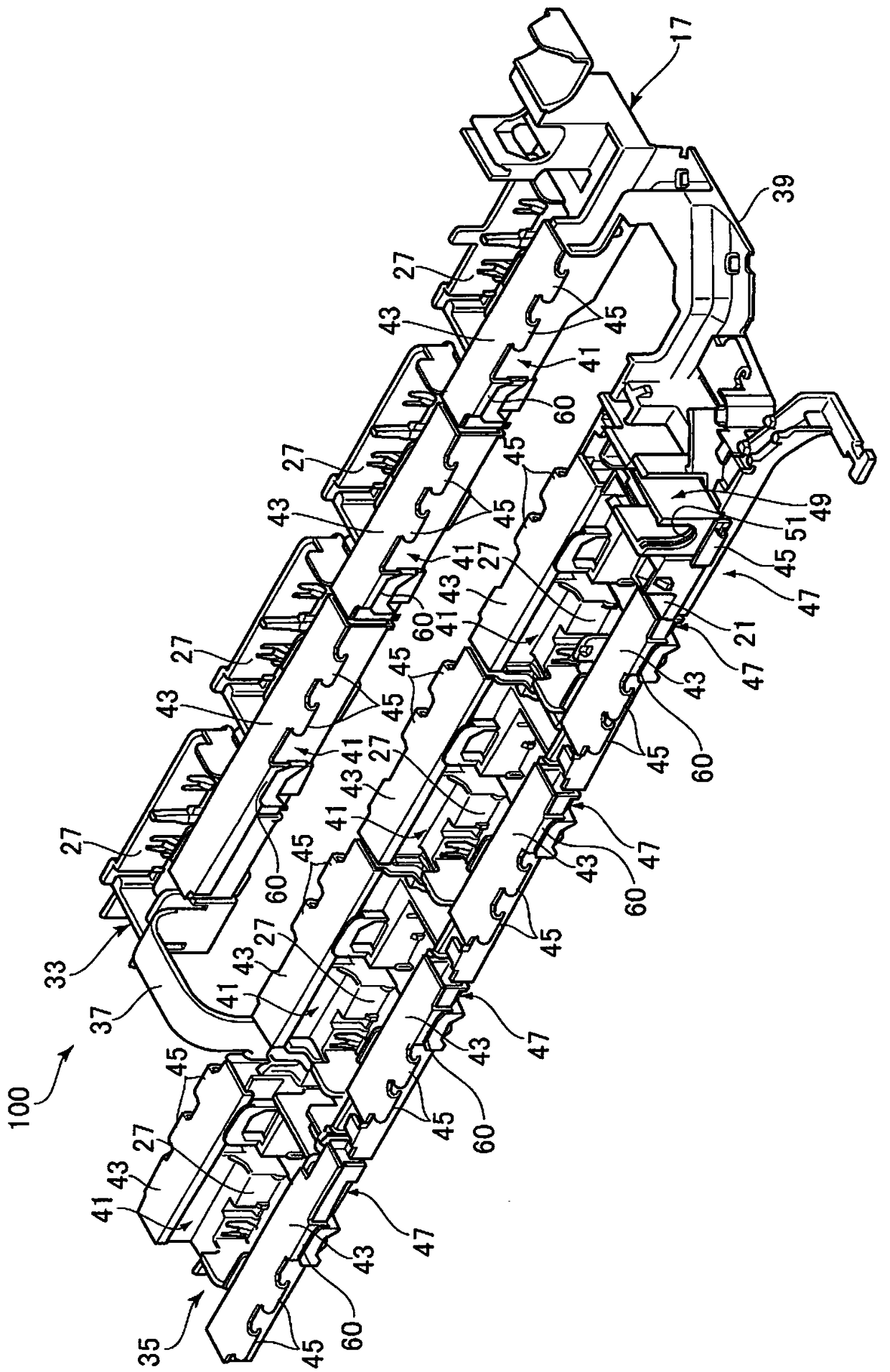

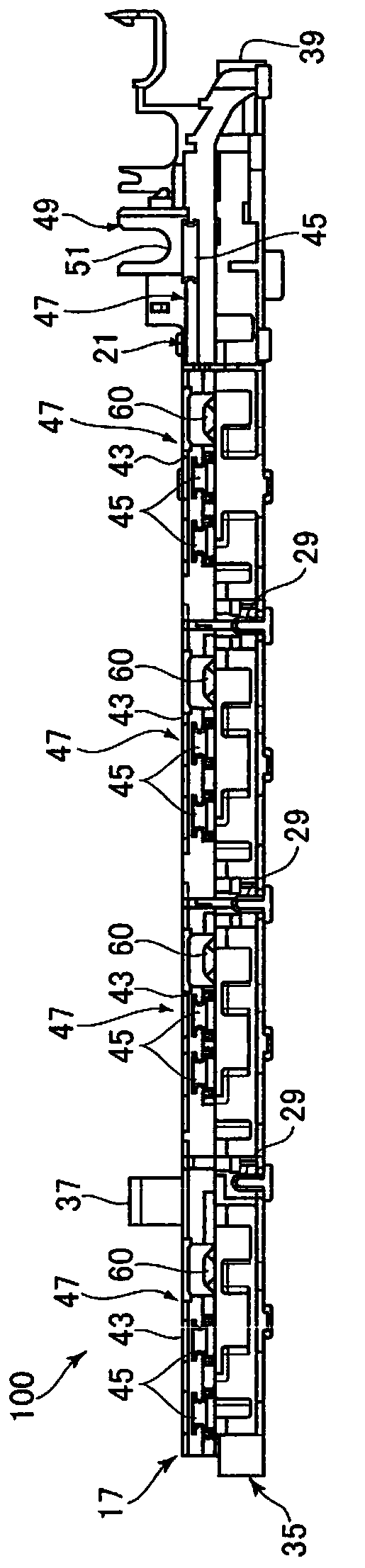

[0039] Hereinafter, the embodiments will be described with reference to the drawings. figure 1 is a schematic plan view of the battery pack 11 equipped with the bus bar module 100 having the wire routing structure according to the embodiment.

[0040] Such as figure 1 As shown, the wire routing structure according to the embodiment will be applicable to the bus bar module 100 . The bus bar module 100 is attached to an assembled battery 15 in which a plurality of single cells 13 are arranged adjacent to each other. The bus bar module 100 and the assembled battery 15 constitute the battery pack 11 .

[0041] In the embodiment, each unit cell 13 is shaped substantially in a plate shape, and has a positive electrode 14 and a negative electrode 16 at both ends in the length direction of a top surface which is a rectangular surface. Although in the embodiment, the positive electrode 14 and the negative electrode 16 are shaped substantially in a bolt shape, the present invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com