Sensor array based on monolayer fluorescent sensing film and its pattern recognition for toxic gases

A sensor array and fluorescent sensing technology, applied in the field of chemical analysis and detection, can solve the problems of high sensor selectivity requirements, limited sensor application range, complex operation, etc., and achieve high-sensitivity differential detection, low cost, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Probe 1 was dissolved in 1-butyl-3-methylimidazolium tetrafluoroborate to prepare a 20 μmol / L ionic liquid solution of probe 1; the ionic liquid solution of probe 1 was mixed with hydrophilic and hydrophobic domains In contact with the gold substrate, an ordered pattern of droplets with a diameter of 50 μm is formed in the region of the hydrophilic mercaptoundecanoic acid monolayer, and a microarrayed monolayer fluorescent sensing film S1 is prepared; the probe 2 is dissolved in In PEG 200, a 65 μmol / L PEG 200 solution of probe 2 was prepared; the PEG 200 solution of probe 2 was brought into contact with a gold substrate having hydrophilic and hydrophobic micro-regions, and a monomolecular layer of hydrophilic mercaptoundecanoic acid The regions form an ordered pattern with a droplet diameter of 50 μm, and a microarrayed monomolecular layer fluorescent sensing film S2 is prepared. According to the above method, prepare 80 μmol / L ionic liquid solution of probe 2, and pre...

Embodiment 2

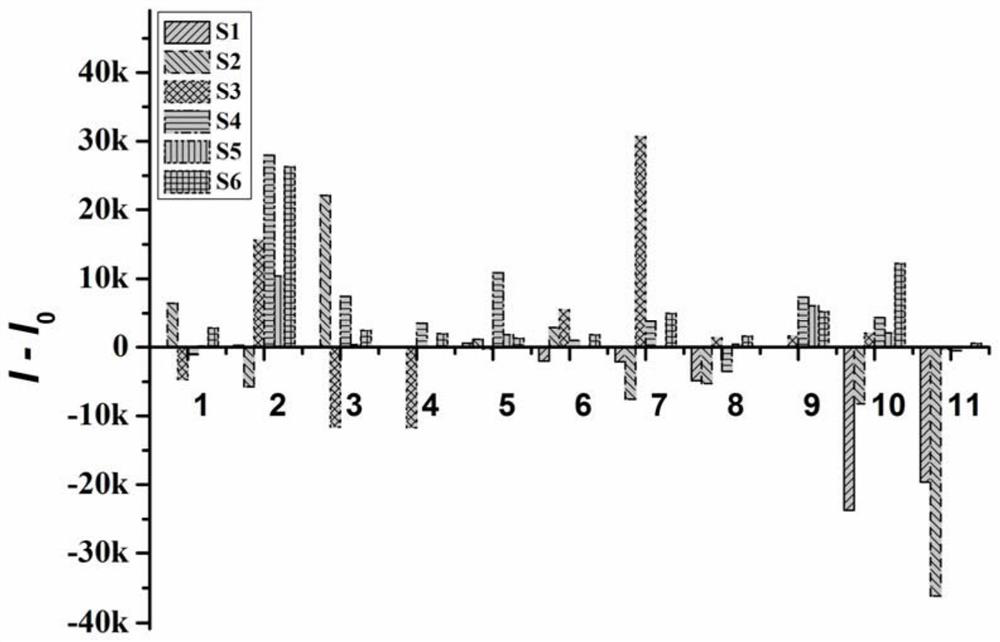

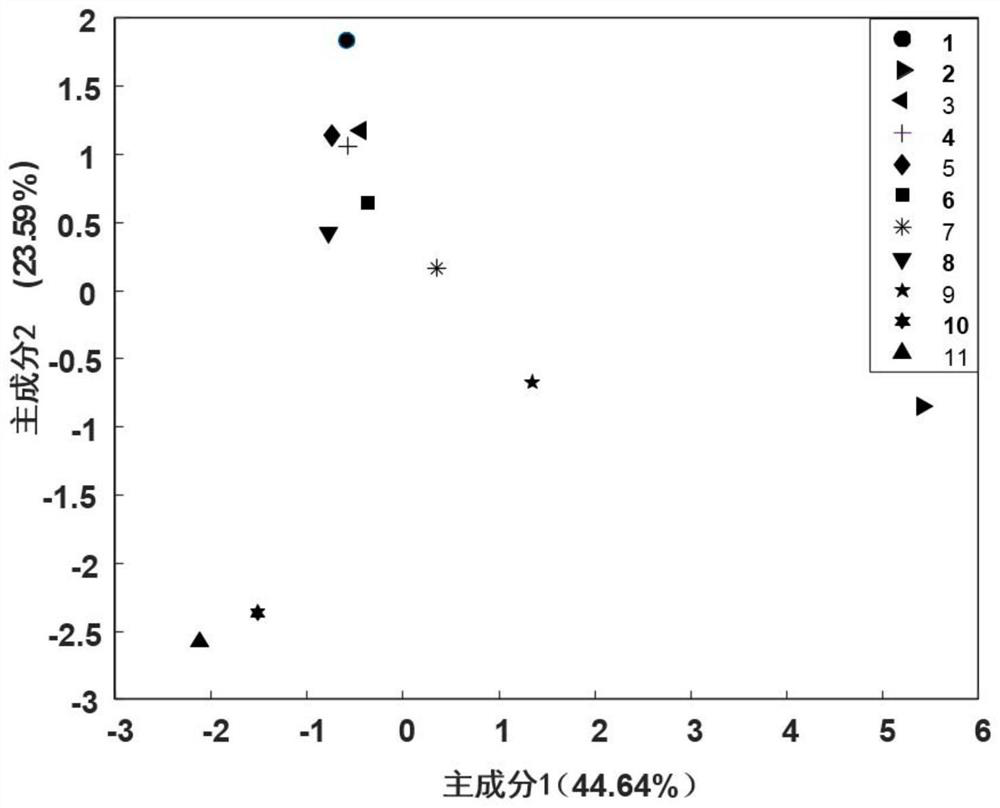

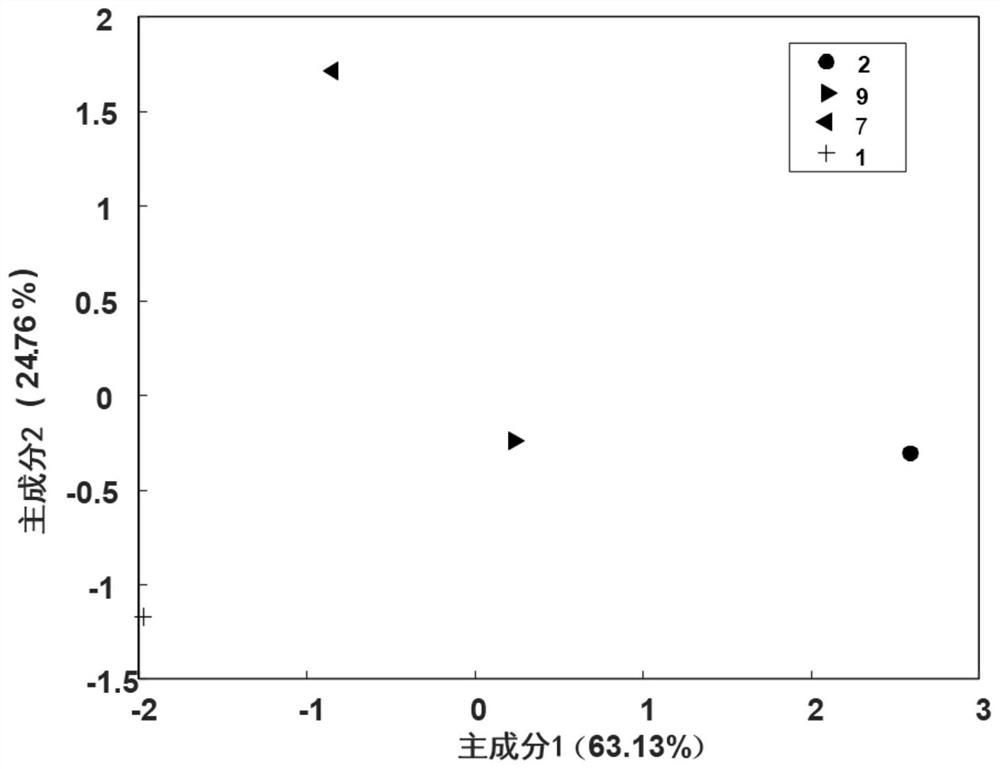

[0024] Adopt the sensor array of embodiment 1 to detect 11 kinds of poisonous gases under the immediately threatening concentration of life and health

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com