Layered gas collecting pipe column assembly and gas collecting device having the same

A technology of gas production pipes and components, which is applied in the field of oil and natural gas exploitation, can solve problems such as gas production, achieve high gas recovery efficiency, improve gas recovery efficiency, and have obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

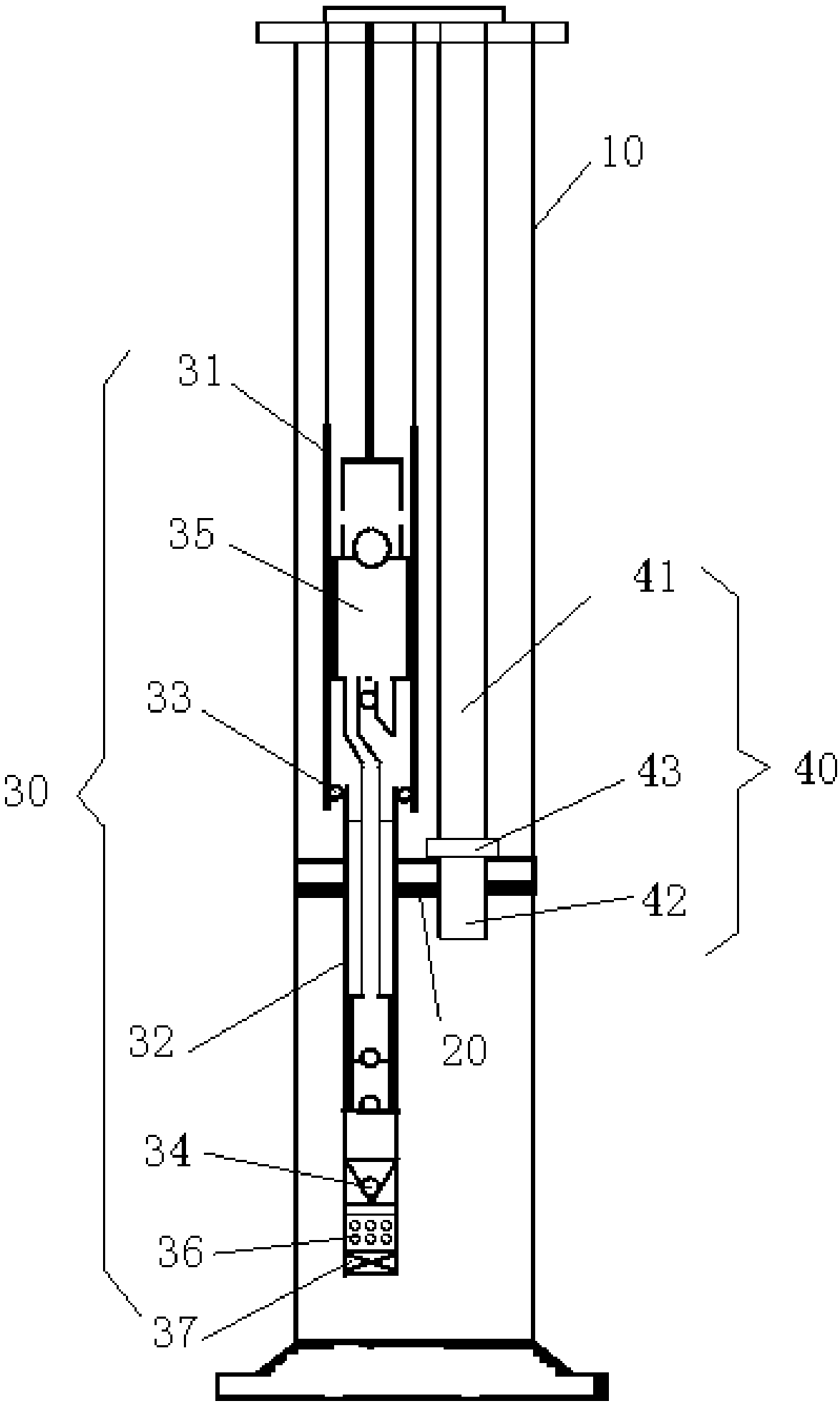

[0034] The difference between the technical solution of Embodiment 2 and Embodiment 1 is that there are two plunger pumps 35 , and the two plunger pumps 35 are respectively arranged in the first drain pipe string 31 and the second drain pipe string 32 . The arrangement of the two plunger pumps 35 enables the two plunger pumps 35 to independently pump and drain the liquid in the upper air layer and the lower air layer.

[0035] The layered gas production string assembly in Embodiment 2 includes: a casing 10, a double-pipe packer 20, a drainage string 30 and a gas production string 40 for gas recovery. The sleeve pipe 10 extends into two gas production layers, and the sleeve pipe 10 communicates with each gas production layer. The double-pipe packer 20 is arranged in the casing 10 and located between the two gas production layers to separate the two gas production layers. The drainage string 30 passes through the double-pipe packer 20 and communicates with each gas production l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com