Device and method for performing automatic welding in long and narrow space

An automatic welding and automatic welding technology, which is applied in the direction of auxiliary devices, welding accessories, welding equipment, etc., can solve the problems of insufficient welding strength, inclusion of foreign matter, difficulty in welding operations, etc., and achieve the effect of multiple functions and small and flexible devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

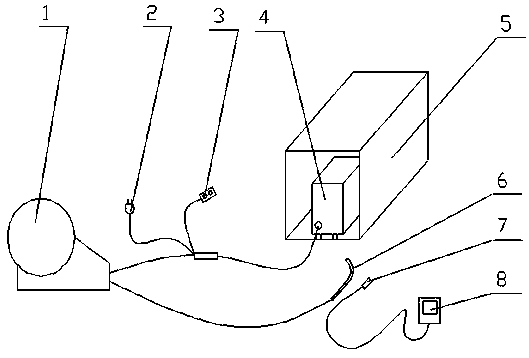

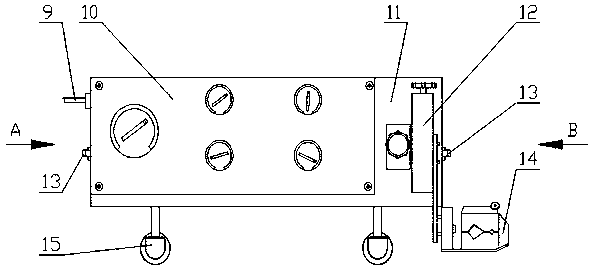

[0024] A device for automatic welding in long and narrow spaces, comprising a wire feeder 1, an automatic welding device 4, a welding torch 6, a peep mirror probe 7 and a peep mirror 8; the wire feeder 1 is connected to a welding torch 6, and the welding torch 6 is arranged on the automatic welding device 4, the peep mirror probe 7 and the automatic welding device 4 are arranged in the workpiece 5, and the peep mirror probe 7 is connected with the peep mirror 8; the automatic welding device 4 includes a drive motor and a control module 10, a trolley chassis 11, and an X-Y adjustment Slider 12, limit switch 13, welding torch fixture 14, magnetic guide wheel 15 and grooved magnetic travel wheel 16; trolley chassis 11 is provided with drive motor and control module 10 and X-Y adjustment slider 12, X-Y adjustment slider 12 is provided with a welding torch clamp 14,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com