Electric-assisted bicycle axle torque sensor and treadmill frequency sensor system

An electric power-assisted bicycle and sensor technology, applied in vehicle parts, transportation and packaging, rider driving, etc., can solve the problems of complex structure of the central axle, the guarantee of fatigue strength is risky, etc., and achieve compact structure, high sensitivity, The effect of stable output signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

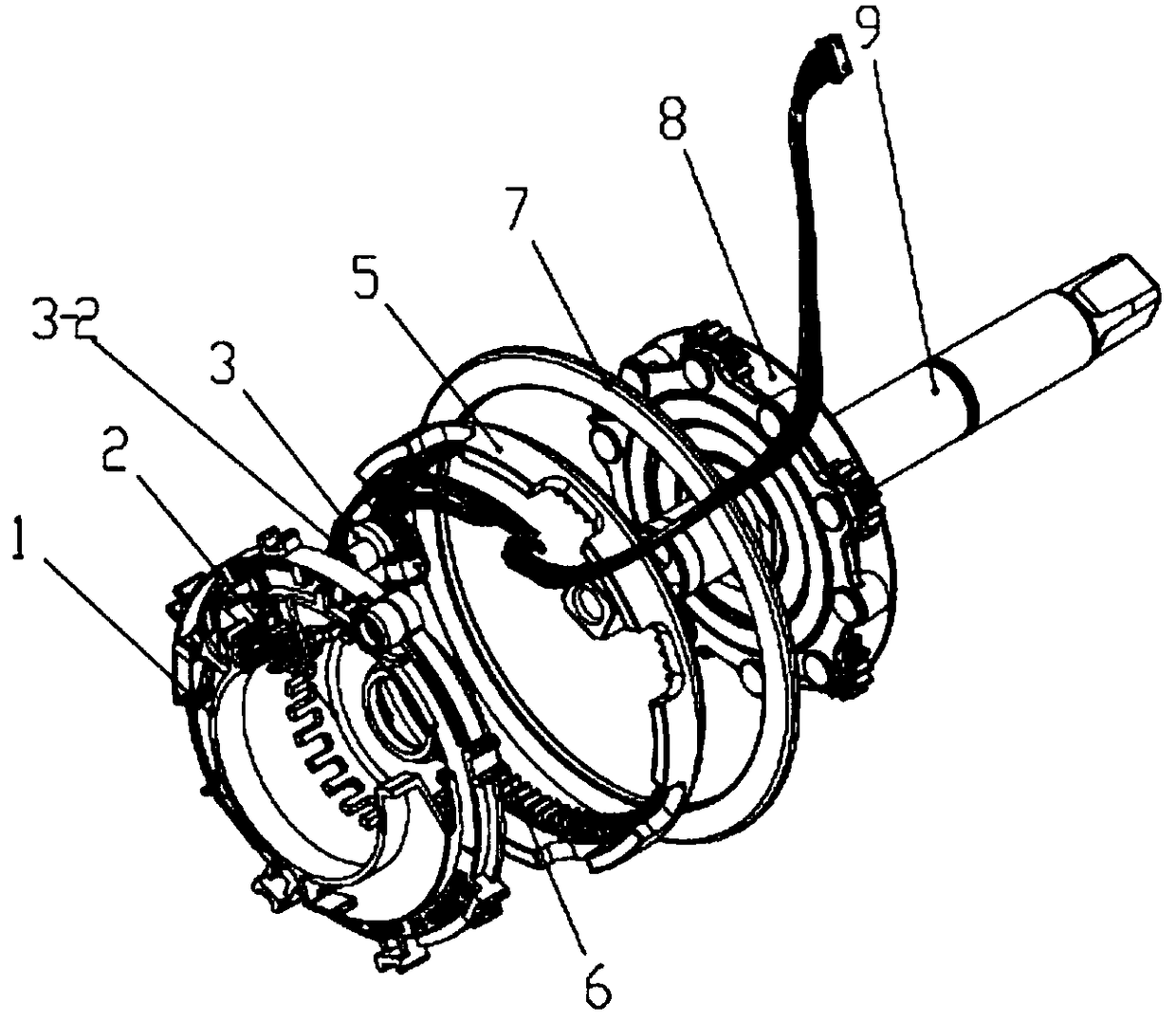

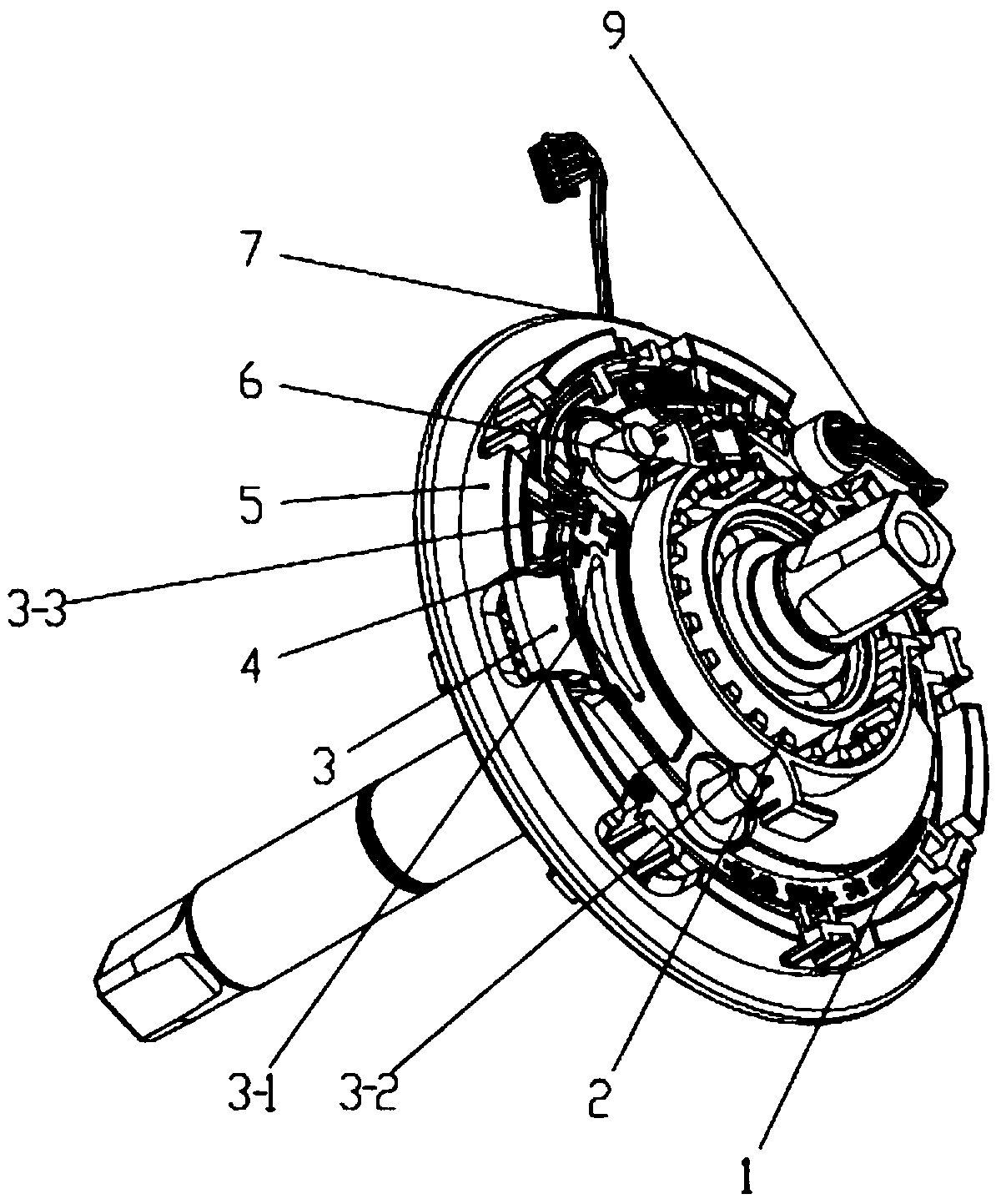

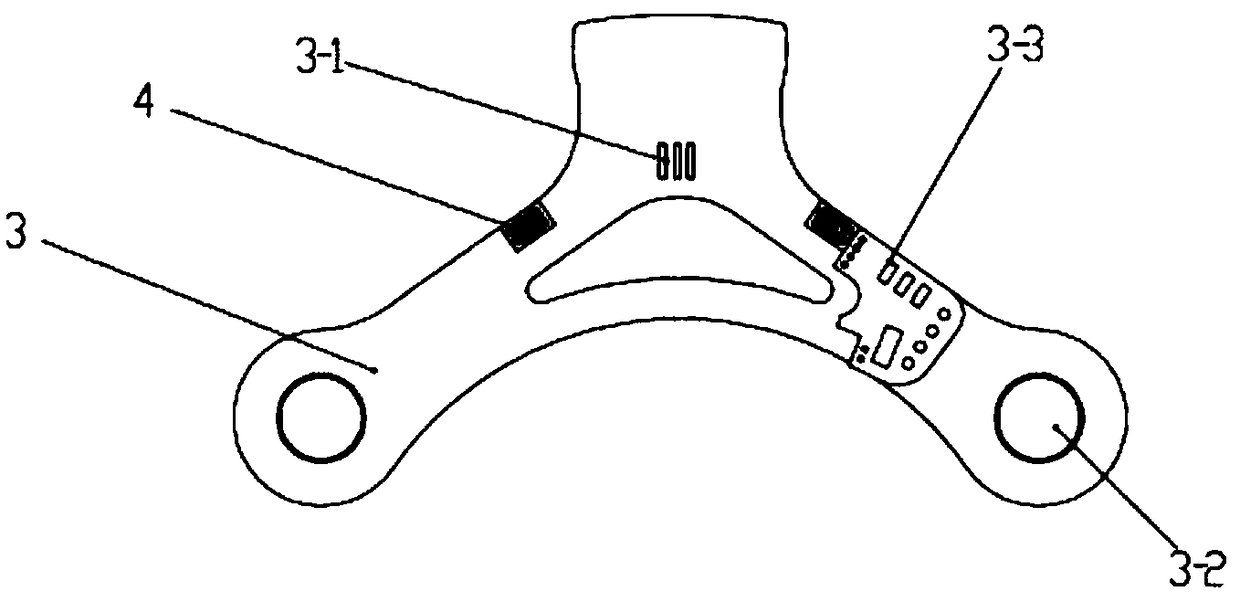

[0016] Such as figure 1 , figure 2 As shown, the present invention includes an elastic element holder 1, an induction gear 2, an elastic element 3, a strain gauge 4, an elastic element limit pin 3-2, a capacitor filter element 3-3, a sun gear 5, and a bidirectional Hall magnet 6 , sun gear cage 7, planetary gear set 8 and central shaft 9. The function of the elastic element holder 1 is to fix the elastic element 3. The main fixing method is through structural limitation. When assembling the elastic element 3, it is only necessary to press the elastic element 3 into the elastic element holder 1. The buckle fixes the position, and maintains the position accuracy of the elastic element through the elastic element holder 1 . The function of the induction gear 2 is mainly to cooperate with the two-way Hall magnet 6 to form a regular waveform. The function of the elastic element 3 is to serve as the carrier of the strain gauge 4 and generate deformation. The function of the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com