Simple manual multi-angle circular tube bending equipment

A multi-angle, manual pipe bending technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of large equipment occupying space, large demand, affecting construction and safety of construction personnel, etc., to achieve light weight and volume. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

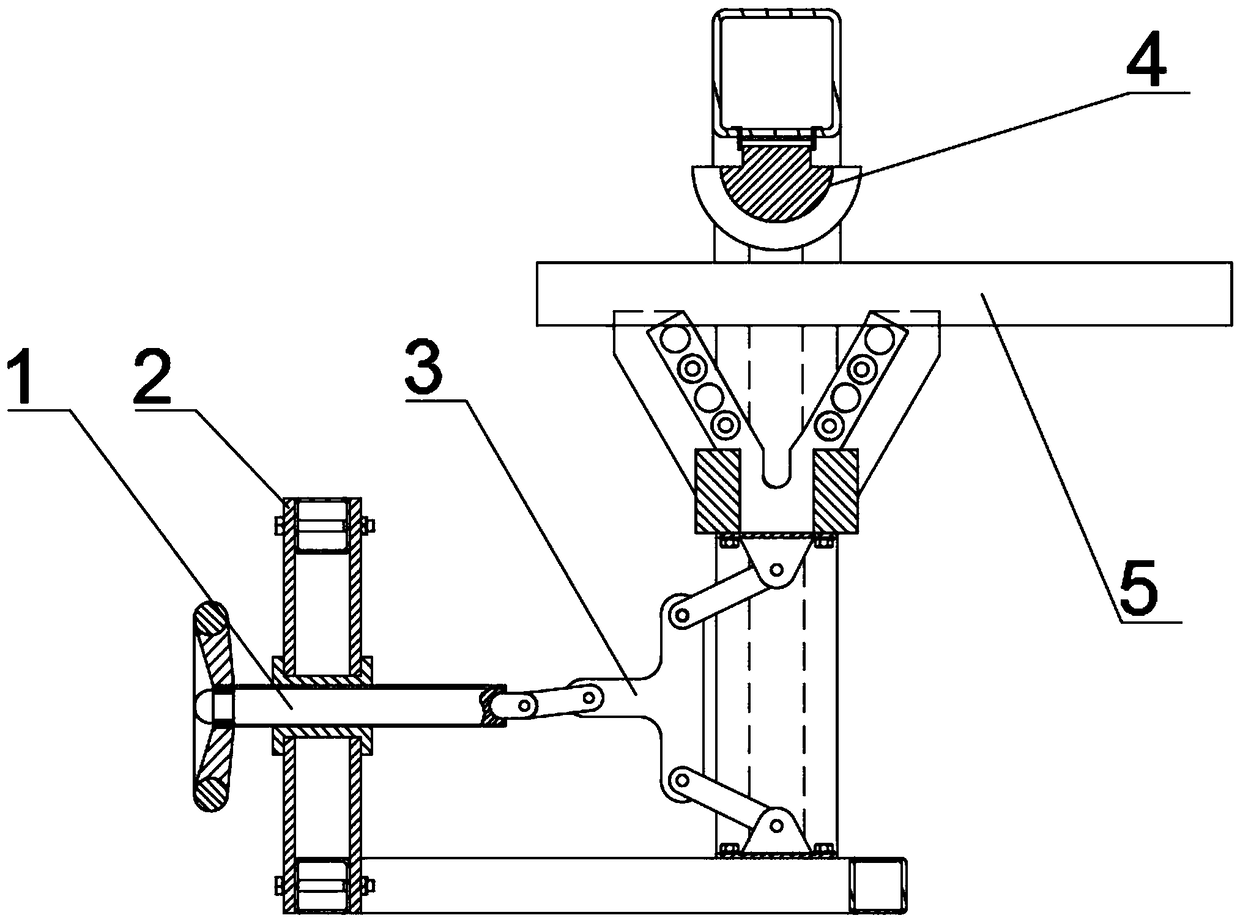

[0032] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 To illustrate this embodiment, the present invention relates to a bending equipment, more specifically, a simple manual circular tube multi-angle bending equipment, including a manual operation combination 1, a support frame combination 2, a lifting combination 3, and a shaping tool combination 4. Round steel pipe 5. This equipment does not need electricity, and can be easily operated manually. It is small in size and light in weight. The position adjustment shaft installed on the rising bracket can adjust the height, thereby changing the bending angle. The shaping tool The combination can be disassembled to change the bending radius of the elbow.

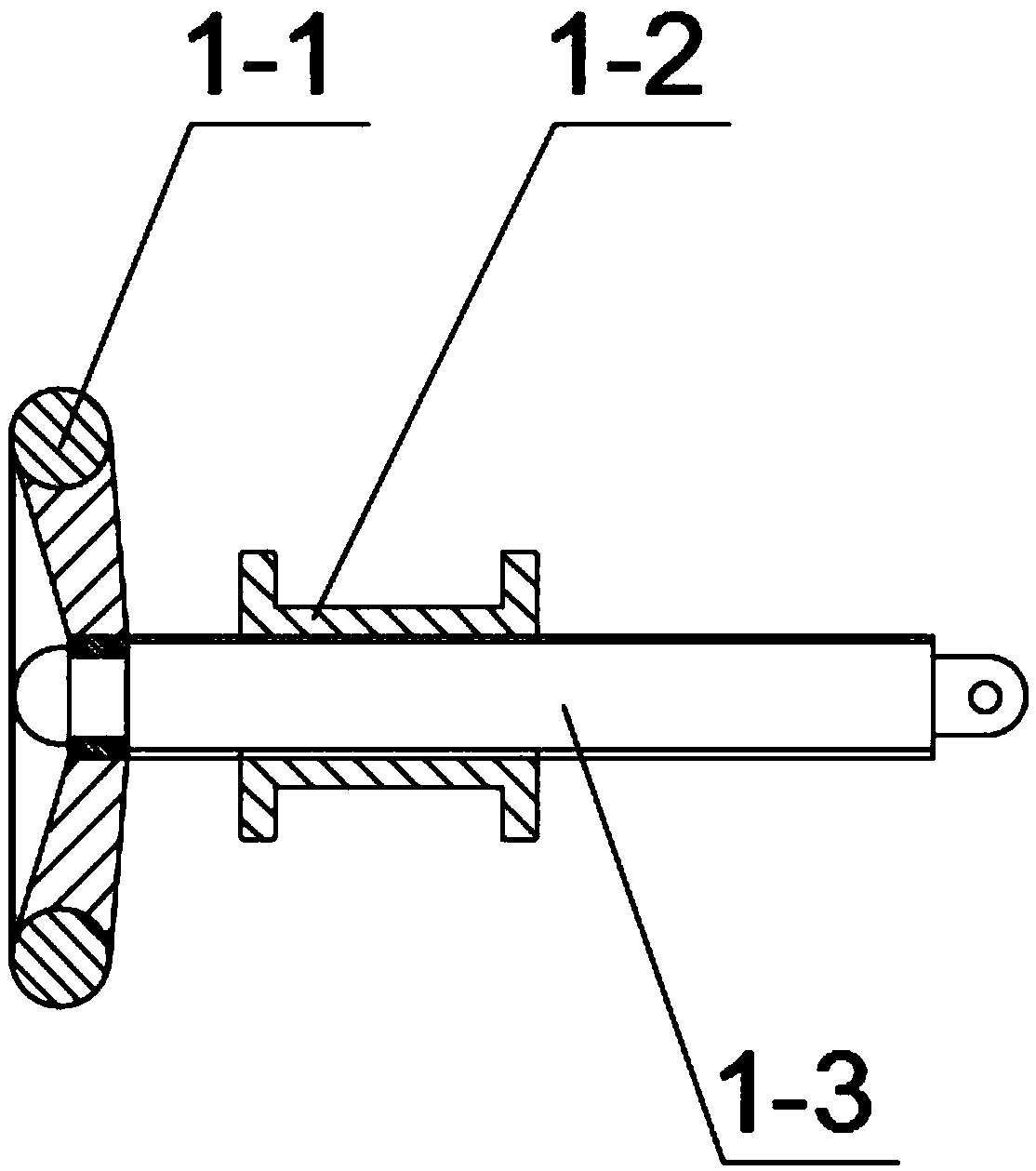

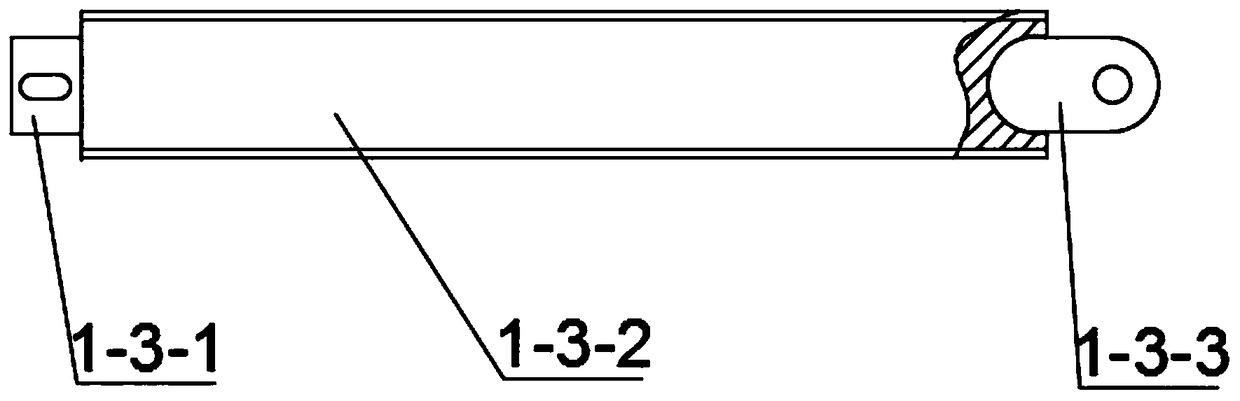

[0033] Manual operation combination 1 is composed of hand wheel 1-1, screw nut 1-2, and screw rod 1-3. Hand wheel 1-1 is installed on the left side of screw nut 1-2, and hand wheel 1-1 is...

specific Embodiment approach 2

[0043] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 This embodiment will be described. This embodiment will further describe Embodiment 1, and the material of the shaping tool assembly 4 is carbon steel.

specific Embodiment approach 3

[0044] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 This embodiment will be described. This embodiment will further describe Embodiment 1, and the number of the lifting brackets 3-2 is two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com