Cooling pipe

A technology of cooling pipes and outer pipes, which is applied in the direction of workpiece cooling devices, workpiece surface treatment equipment, metal rolling, etc., and can solve the problem of optimal cooling water flow rate and pressure, unsatisfactory metallographic structure, uneven cooling of rolled pieces, etc. problem, to avoid the effect of uneven cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention provides a cooling pipe. On the one hand, its unique structural design reduces the flow rate of cooling water in the pipe, which slows down the rapid cooling speed of the surface of the rolled piece. On the other hand, it also maintains a certain water pressure in the pipe, avoiding the Uneven cooling.

[0026] In order to enable those skilled in the art to better understand the solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

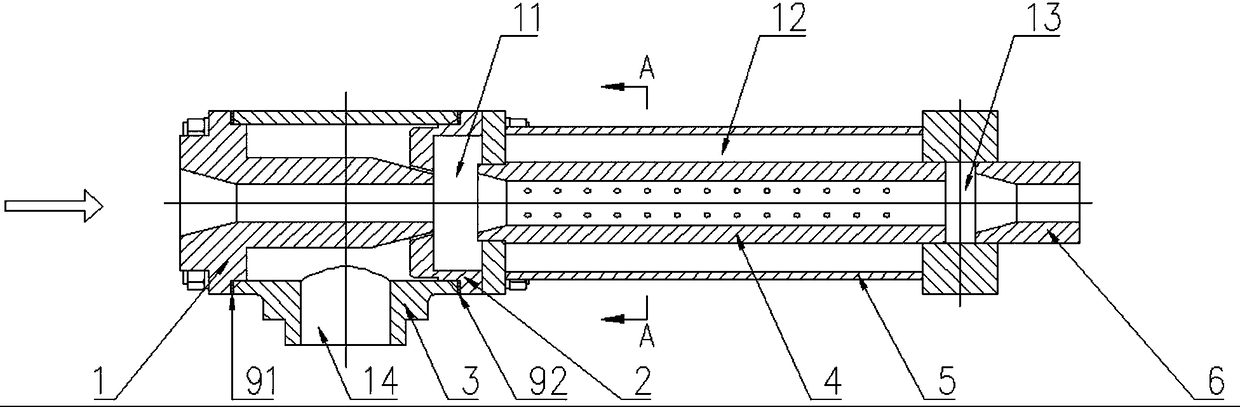

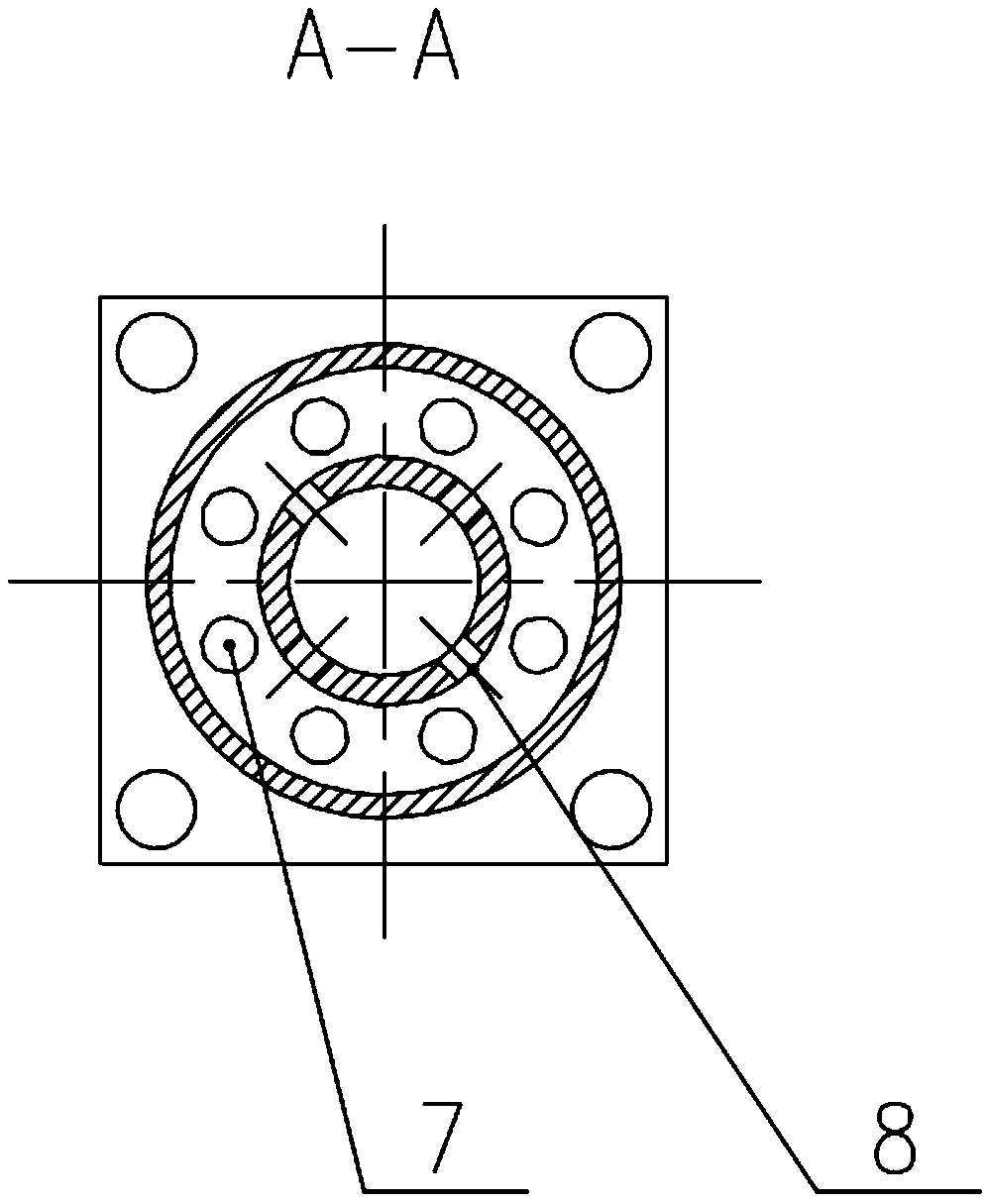

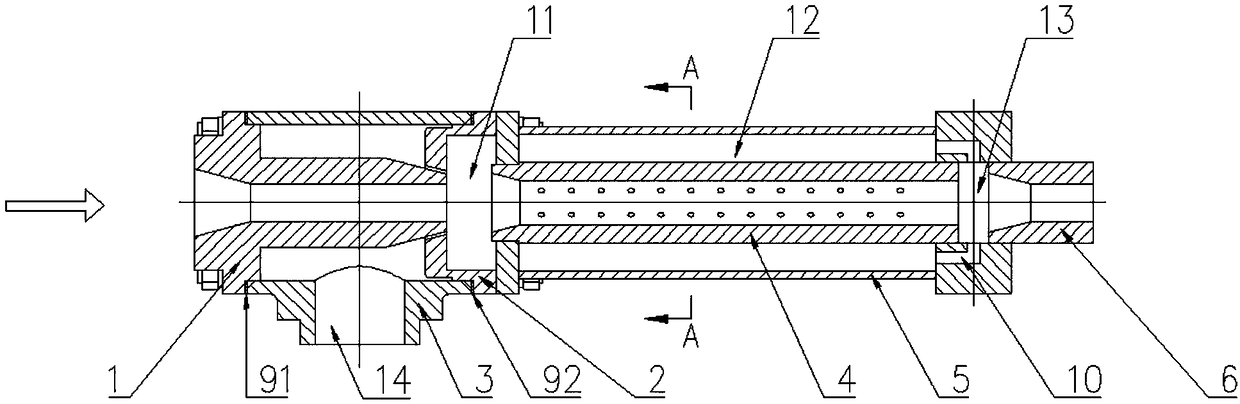

[0027] see figure 1 and figure 2 , a cooling pipe provided in the present invention, comprising a first nozzle 1, a second nozzle 2, an outer pipe 5, an inner conduit 4 and a water inlet 14;

[0028] Wherein, both the first nozzle 1 and the second nozzle 2 are connected at both ends, and are coaxially arranged to form a relative position with an annular water spray port, the inner diameter of the second nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com