Captive breeding cage capable of automatically feeding livestock with water and fodder

A livestock and feeding technology, applied in the field of breeding, can solve the problems of decay and deterioration, reducing the cleanliness of livestock diet, frequent cleaning cycles of livestock pens, etc., to achieve the effect of reducing cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

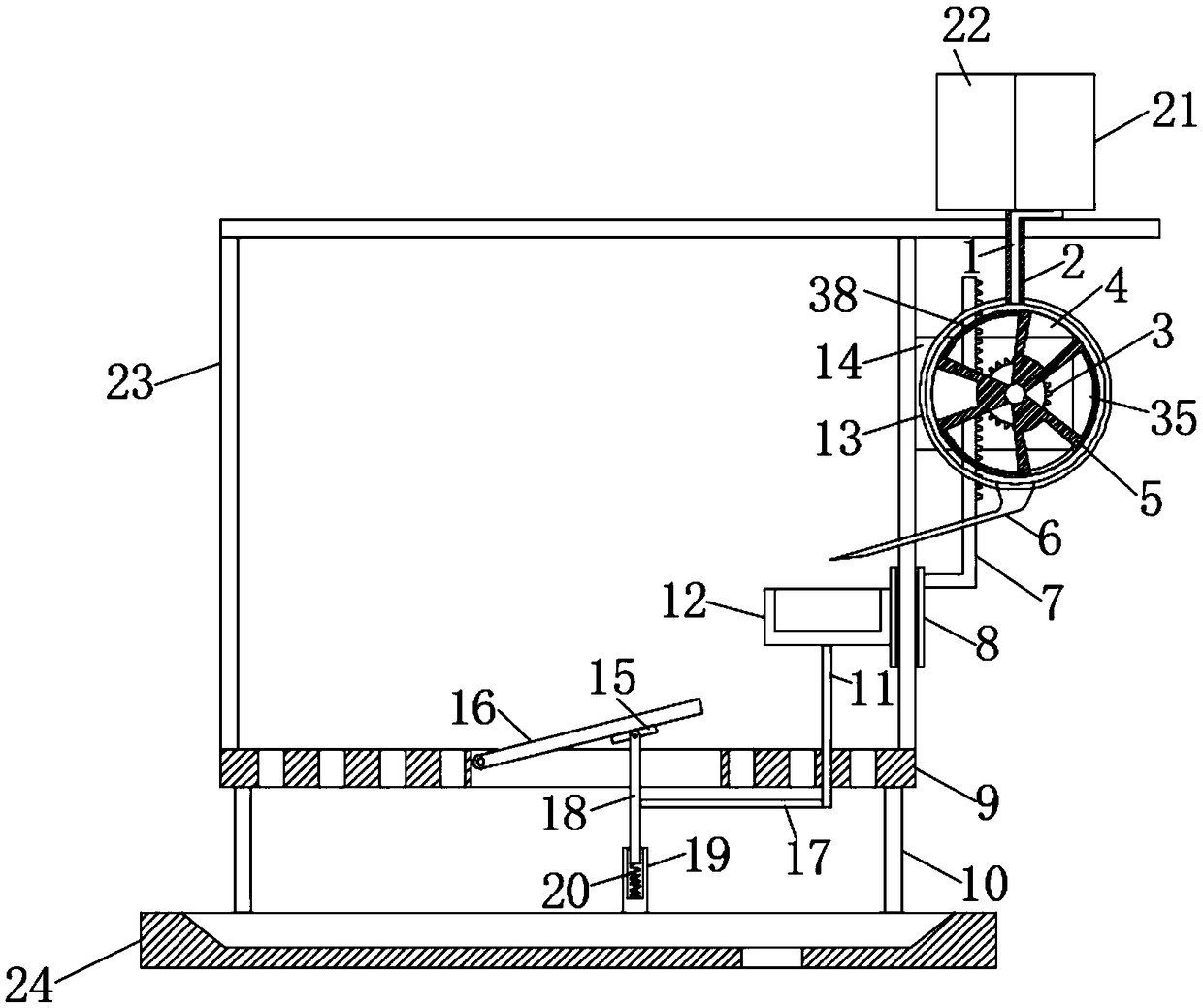

Method used

Image

Examples

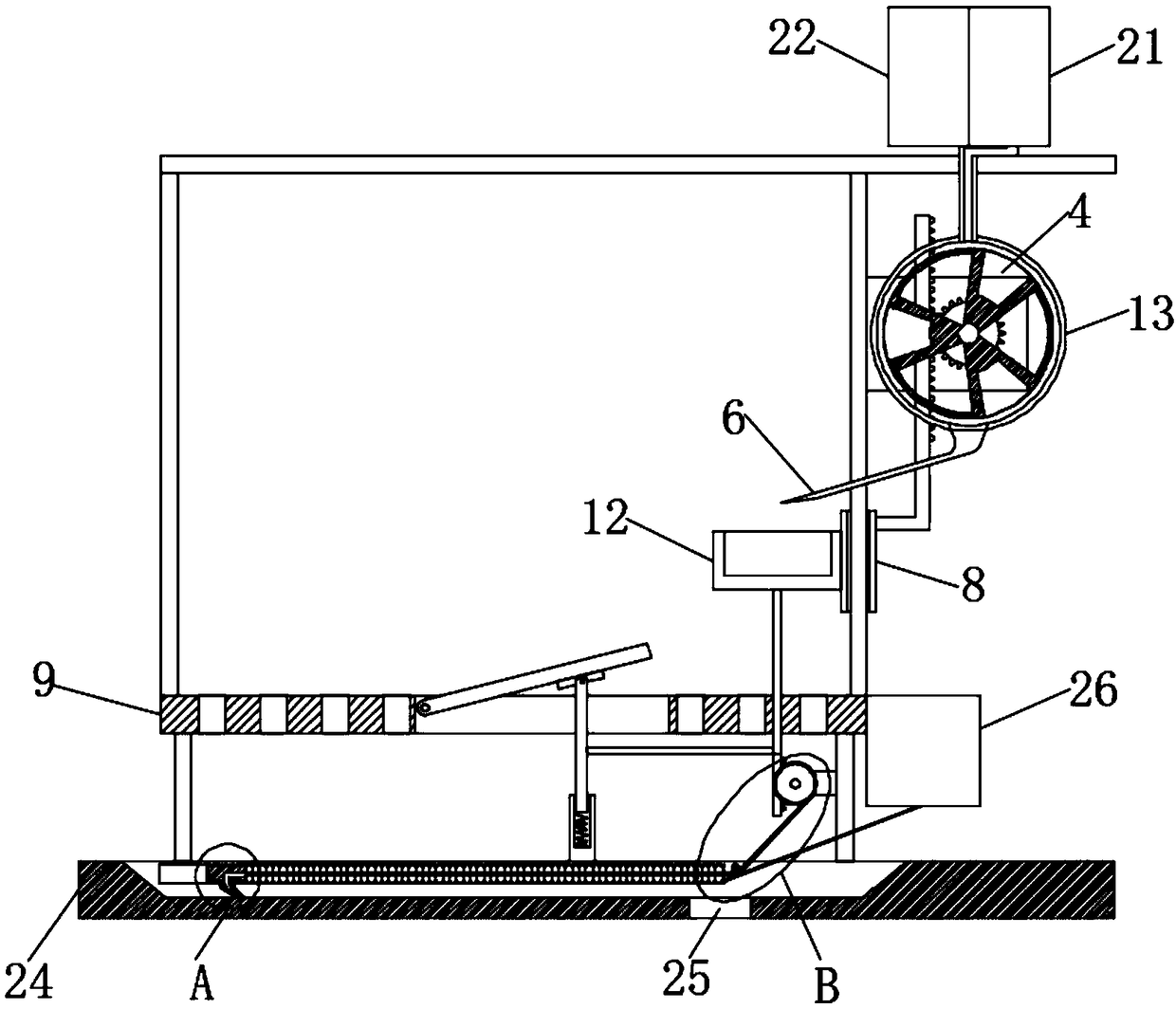

Embodiment 2

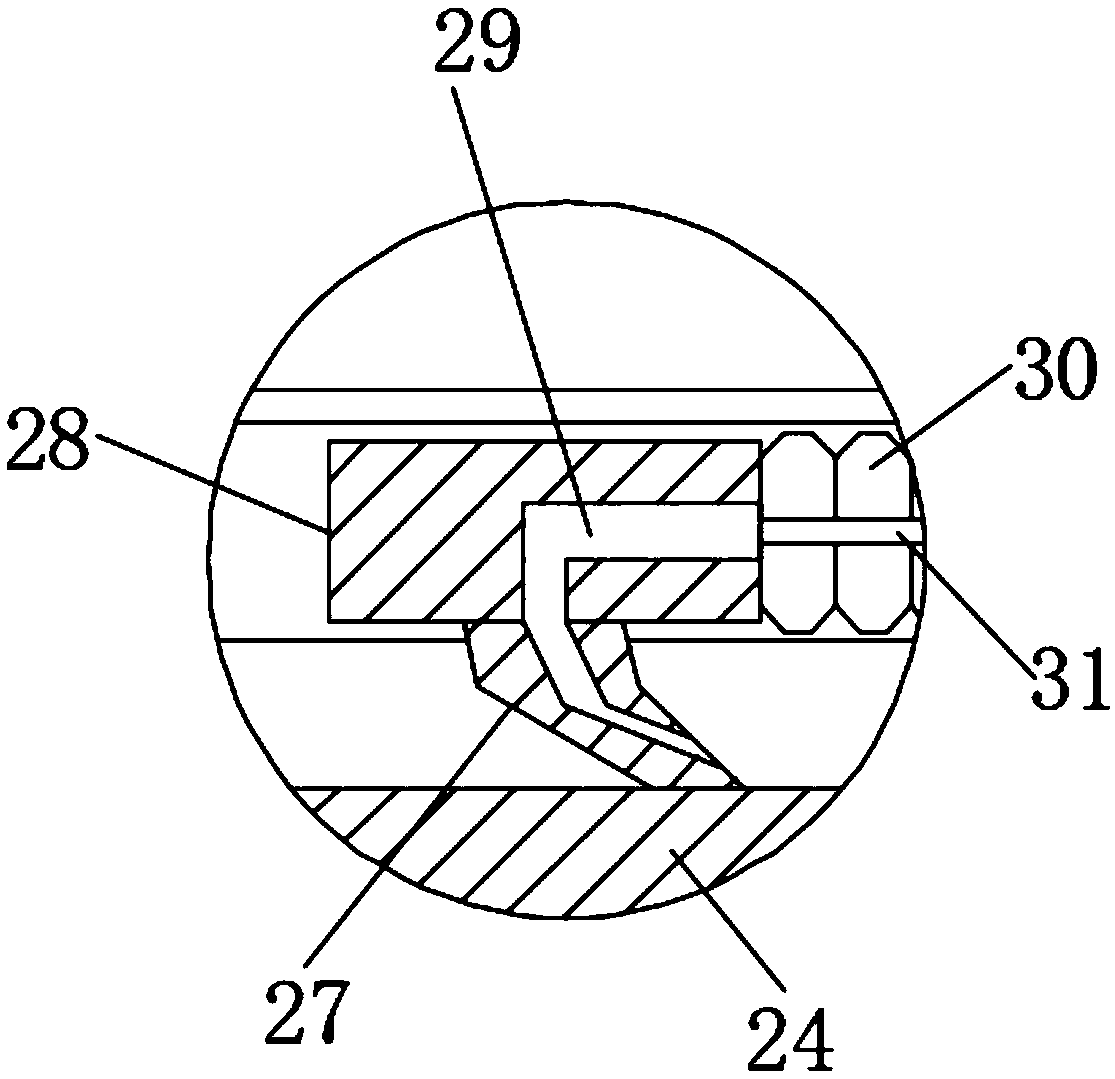

[0025] refer to Figure 2-5 , different from Embodiment 1, the lower end of the movable rod 11 is fixedly connected with the second rack 33, the side wall of the connecting rod 10 is fixedly connected with the mounting plate 34, and the side wall of the mounting plate 34 is rotatably connected with the second rack 33 The meshed second gear 40, the side wall of the second gear 40 is coaxially fixedly connected with the winding roller 32, the side wall of the tray 24 is rotatably connected with the reversing wheel 39, and the opposite inner side wall of the tray 24 is provided with a chute, A slide plate 28 is slidably connected between the two chutes, and the lower end of the slide plate 28 is fixedly connected with a scraper 27 which is always in contact with the inner bottom of the tray 24. A traction line 31 is connected to the winding roller 32, and the traction line 31 bypasses the redirection Wheel 39 is also fixedly connected on the side wall of slide plate 28, and water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com