Low-temperature contact type surface temperature sensor

A temperature sensor and surface temperature technology, applied to thermometers, thermometer parts, thermometers with direct heat-sensitive electric/magnetic elements, etc., can solve the difficulty of replacing or maintaining temperature sensors, reduce the overall performance of the measured object, Accuracy is susceptible to external influences and other issues, to achieve the effect of improving temperature measurement efficiency, high accuracy, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

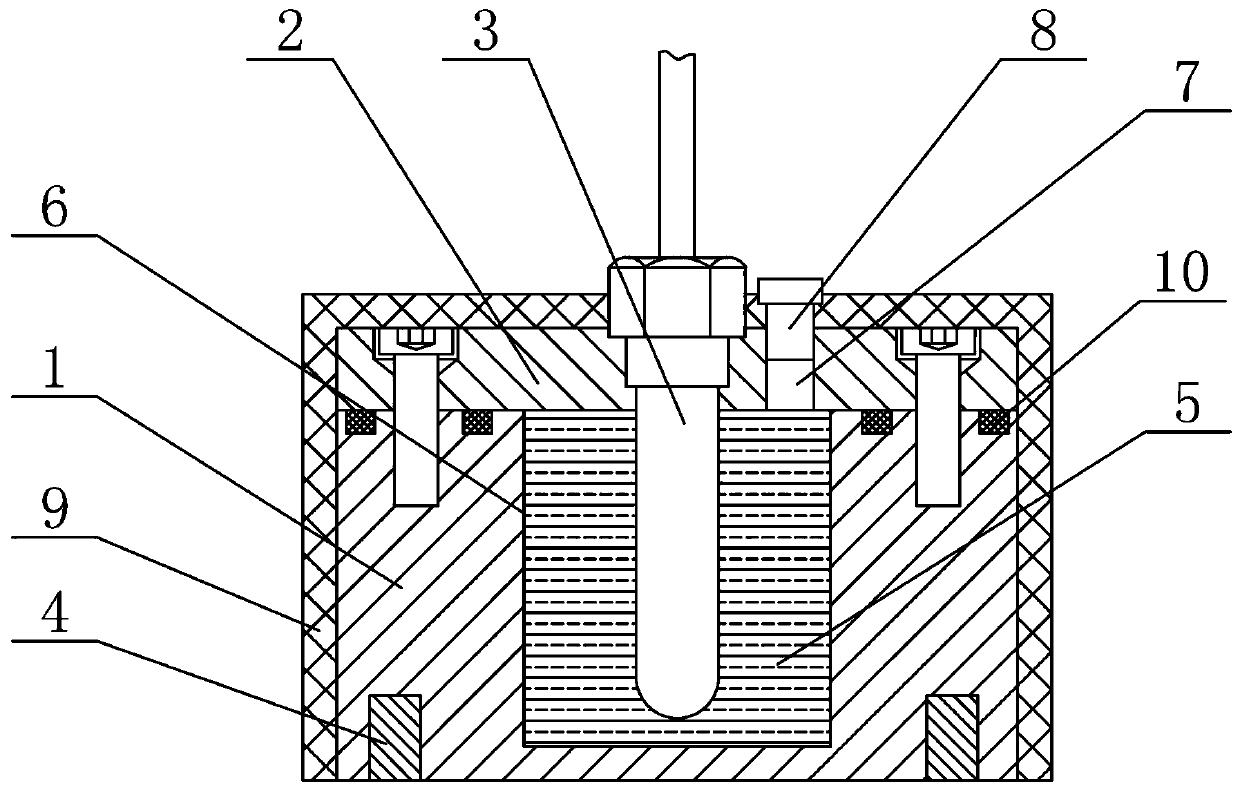

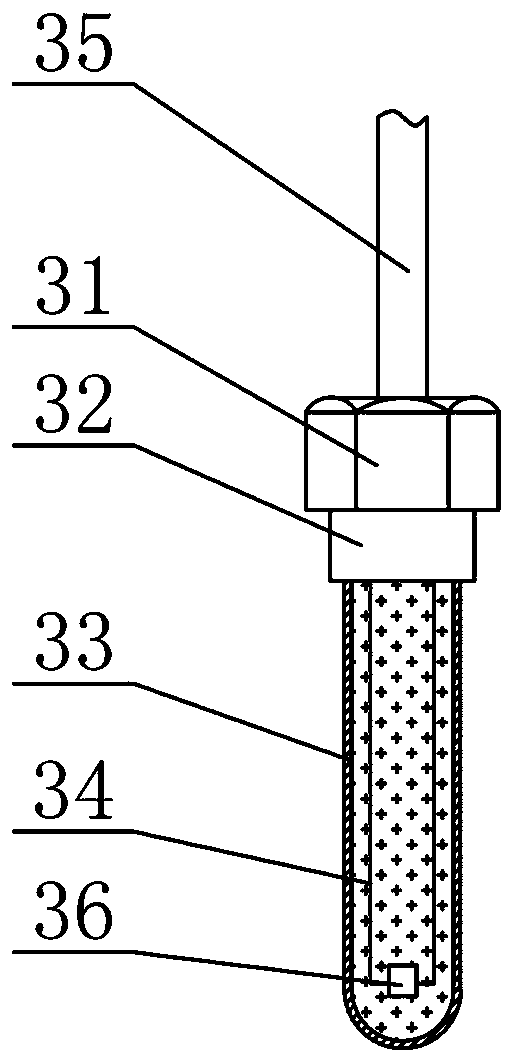

[0026] Such as figure 1 , figure 2 As shown, a low-temperature contact surface temperature sensor, which includes a housing 1, an upper cover 2, a temperature sensor 3, a magnet ring 4 and a temperature uniform medium 5, the housing 1 is a cylindrical pure aluminum housing, The lower end of the housing 1 is provided with an annular slot, and the annular slot at the lower end of the housing 1 is arranged near the edge of the housing 1. The magnet ring 4 is housed in the annular slot, and the depth of the annular slot is the same as that of the magnet ring. 4 have the same height, the housing 1 is provided with a uniform temperature tank 6, the distance between the bottom surface of the temperature uniform tank 6 and the lower end surface of the housing 1 is 0.2~1 mm, and the upper end of the housing 1 is provided with an upper cover 2. The cover 2 seals the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com