Monitoring device for deformation of ballastless track plate

A ballastless track and monitoring device technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of cumbersome operation, low monitoring accuracy, endangering the safety of operating trains, etc., and achieve high monitoring accuracy, easy maintenance and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

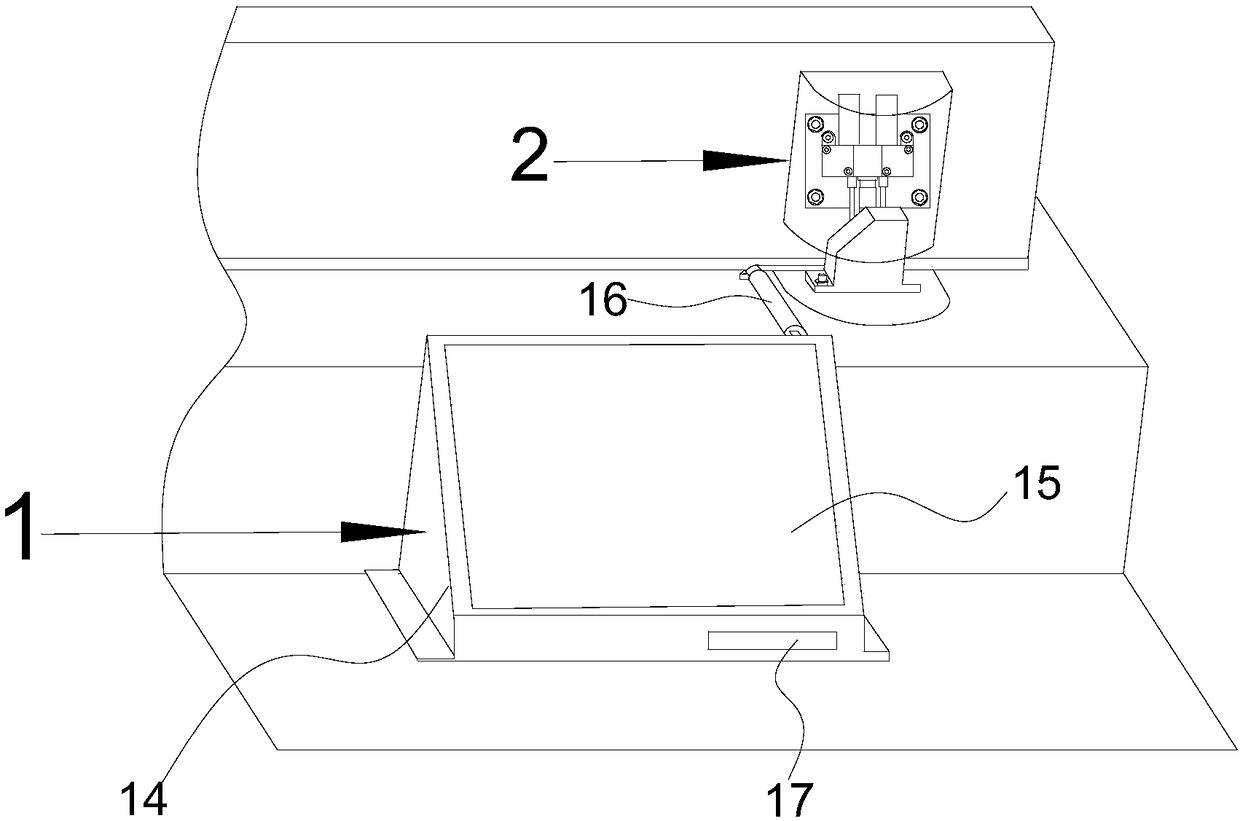

[0025] A monitoring device for deformation of a ballastless track slab includes an energy delivery unit 1 and a monitoring mechanism 2 communicatively connected with the energy delivery unit 1 . The energy delivery unit 1 provides electric energy for the device, and ensures the stable operation of the monitoring mechanism 2 under the electric energy guarantee of the energy output unit.

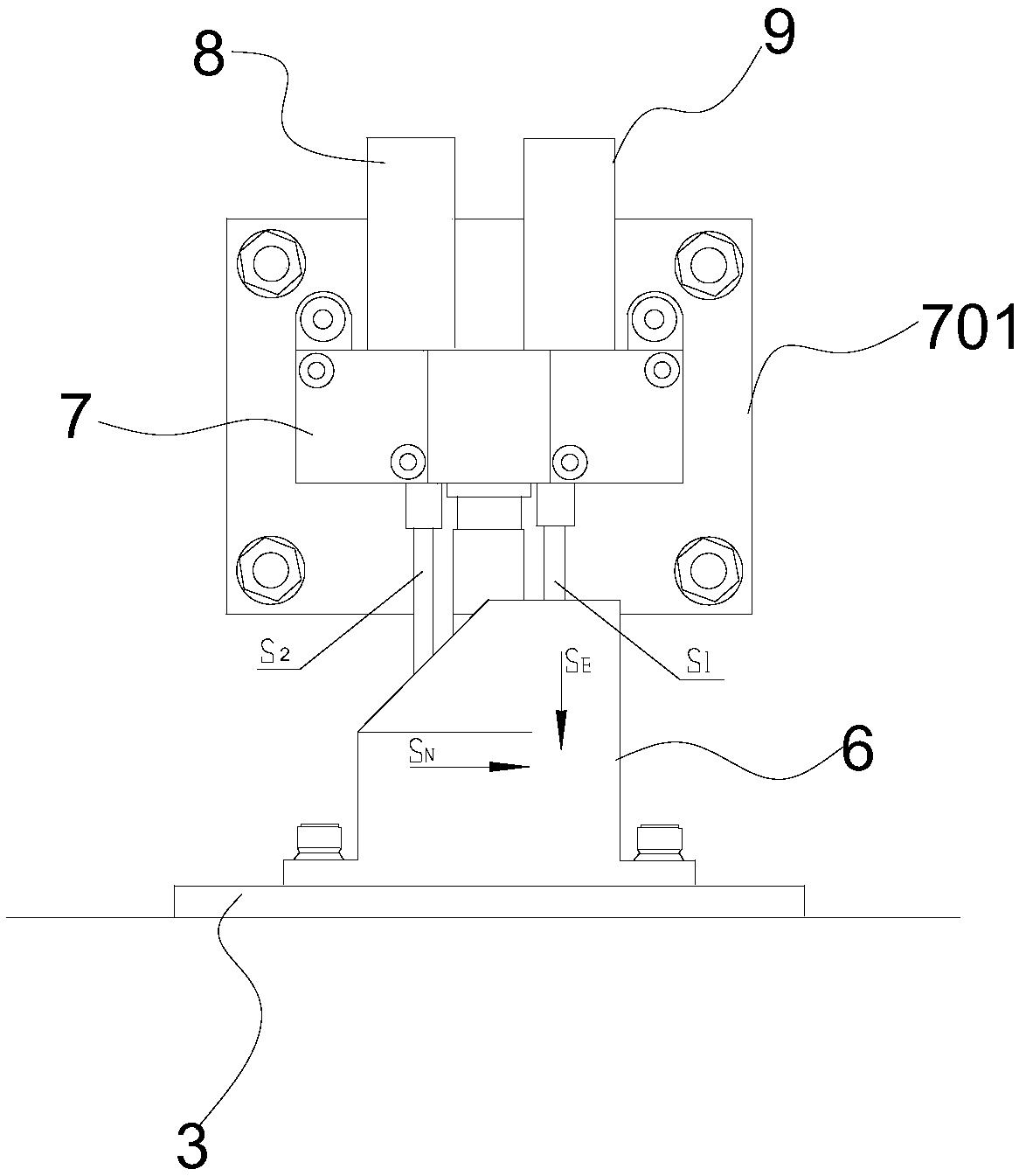

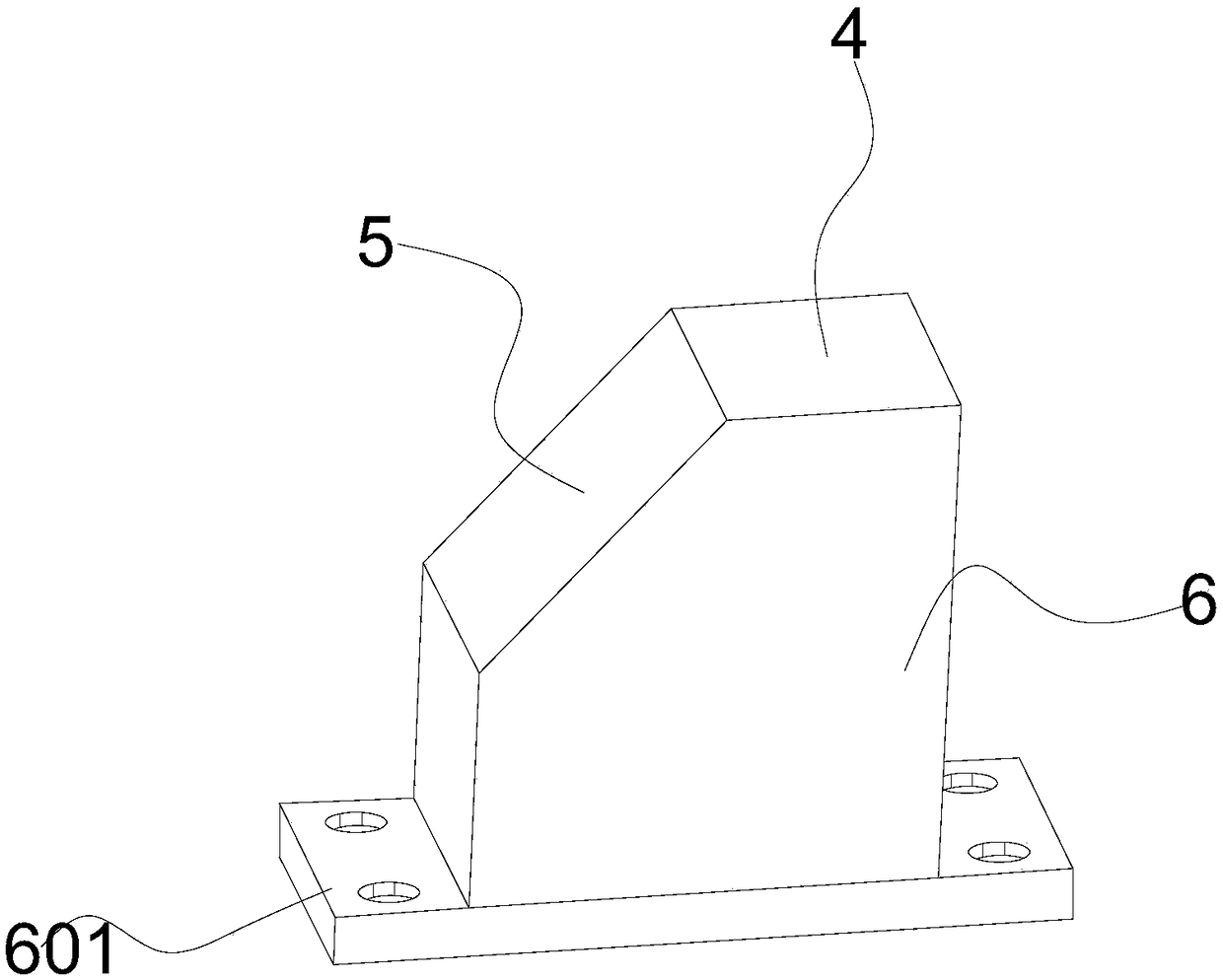

[0026] The monitoring mechanism 2 includes a base 3 , an installation block 6 arranged on the base 3 and having a horizontal top surface 4 and an inclined surface 5 , and a seam gauge with double probes in contact with the installation block 6 .

[0027] The base 3 of the monitoring mechanism 2 is a rectangular semicircular stainles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com