Electric control valve

A technology of electric control valves and valve bodies, applied in valve details, multi-way valves, valve devices, etc., can solve the problems of slow valve opening speed, long response time, poor wax thermal expansion effect, etc., to improve cooling speed and ensure No overheating, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

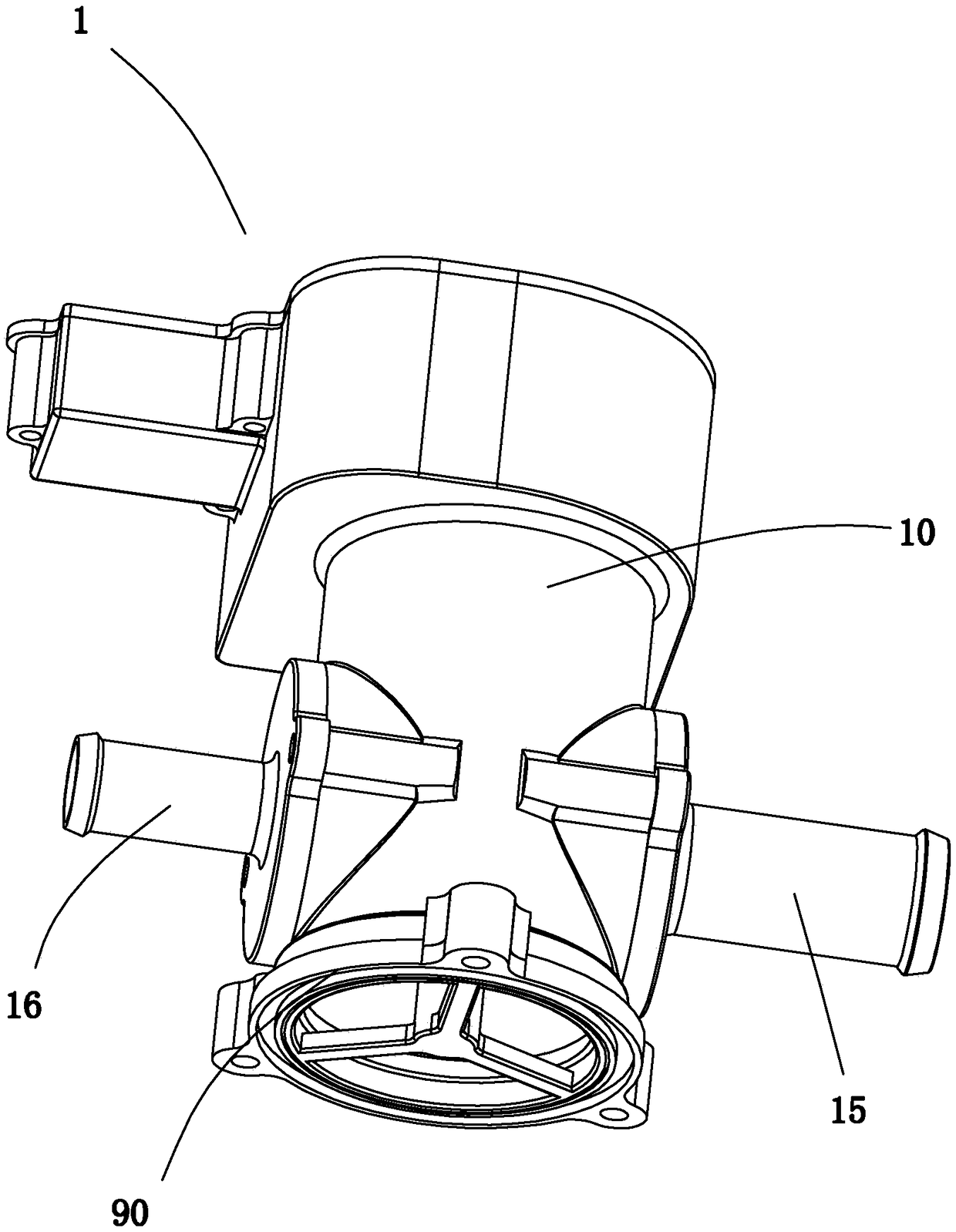

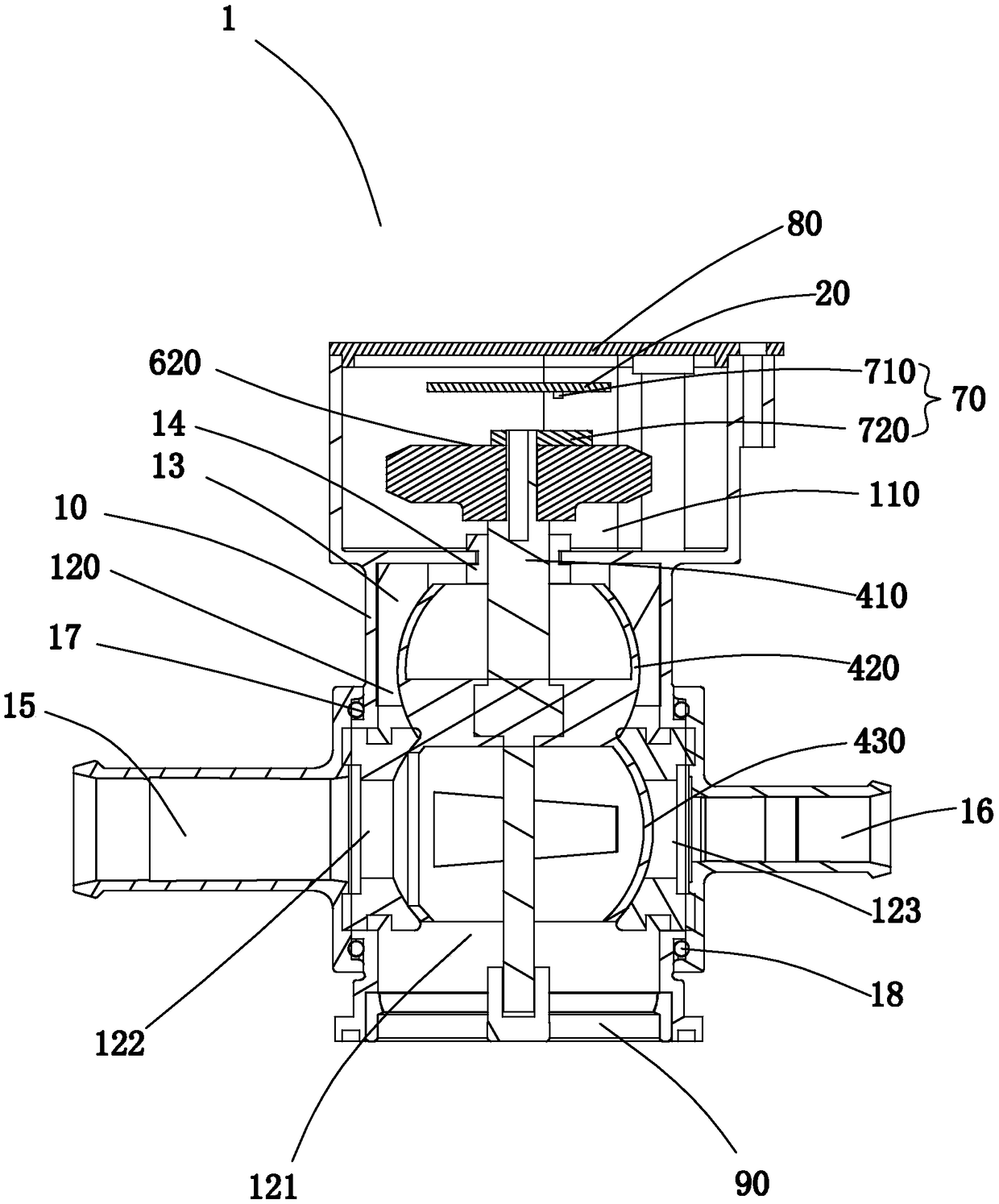

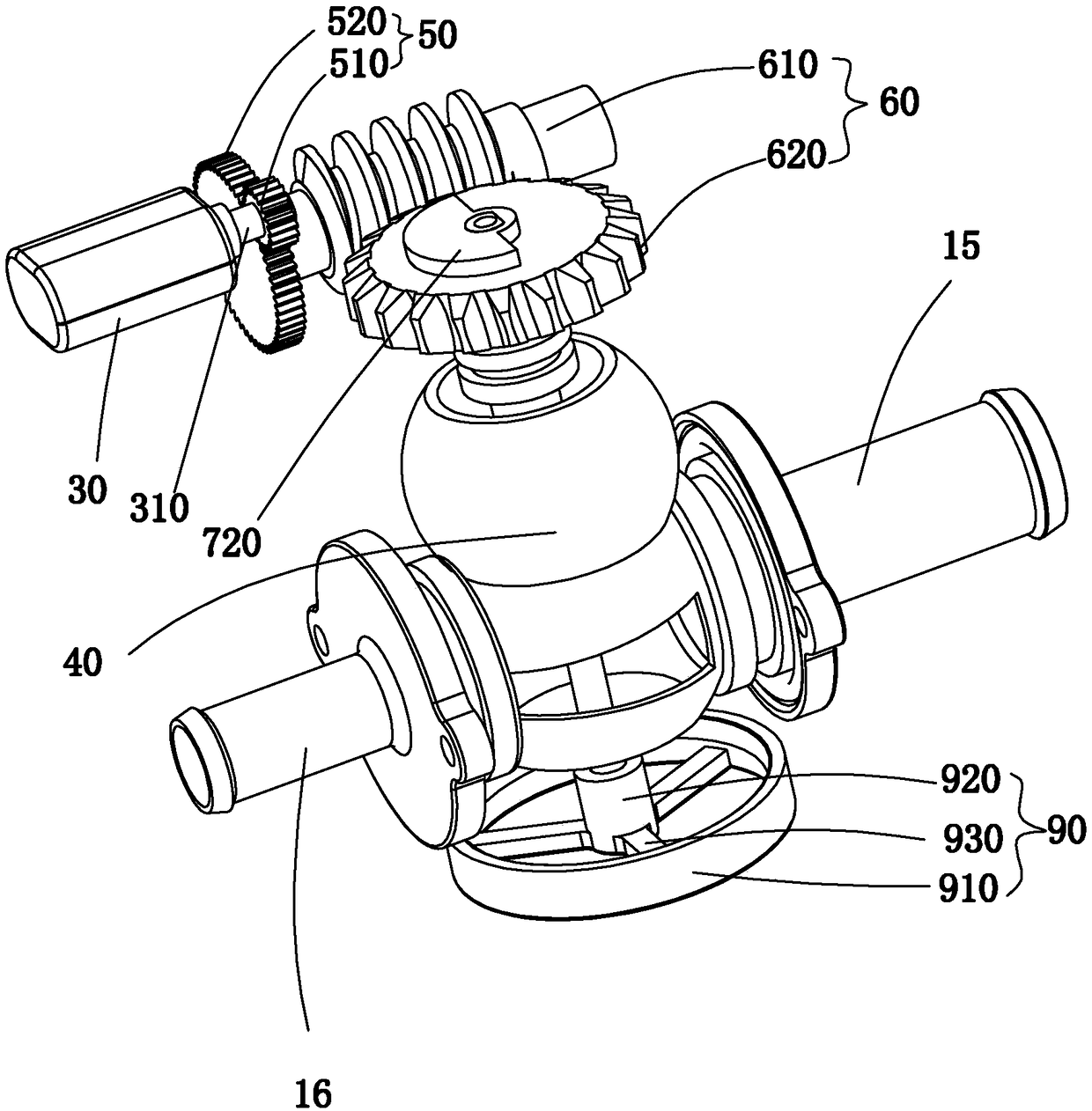

[0020] Such as Figures 1 to 3 As shown, an electric control valve 1 may include a valve body 10 , a circuit board 20 , a motor 30 , a transmission mechanism and a spherical valve core 40 . The valve body 10 can be integrally formed, and has an upper chamber 110 and a lower chamber 120 that are hermetically separated. The circuit board 20, the motor 30 and the transmission mechanism are arranged in the upper chamber 110. The circuit board 20 is electrically connected with the motor 30 to control the rotation of the motor 30. The output shaft 310 of the motor 30 is connected to the rotating shaft 410 of the spherical valve core 40 through the transmission mechanism. Drive connection, the lower chamber 120 is provided with a water inlet 121 located at the bottom and two water outlets 122, 123 located on the side, one large and one small, the spherical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com