Method for applying multi-axis robot to cell factories to prepare biological products

A multi-axis robot, biological product technology, applied in biochemical equipment and methods, tissue cell/virus culture devices, specific-purpose bioreactors/fermenters, etc., can solve the problem of increasing production costs and the number of workers, Unfavorable culture growth and expansion, high difficulty in sterile environment control, to achieve the effect of facilitating large-scale and efficient production, reducing human intervention, and achieving good product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

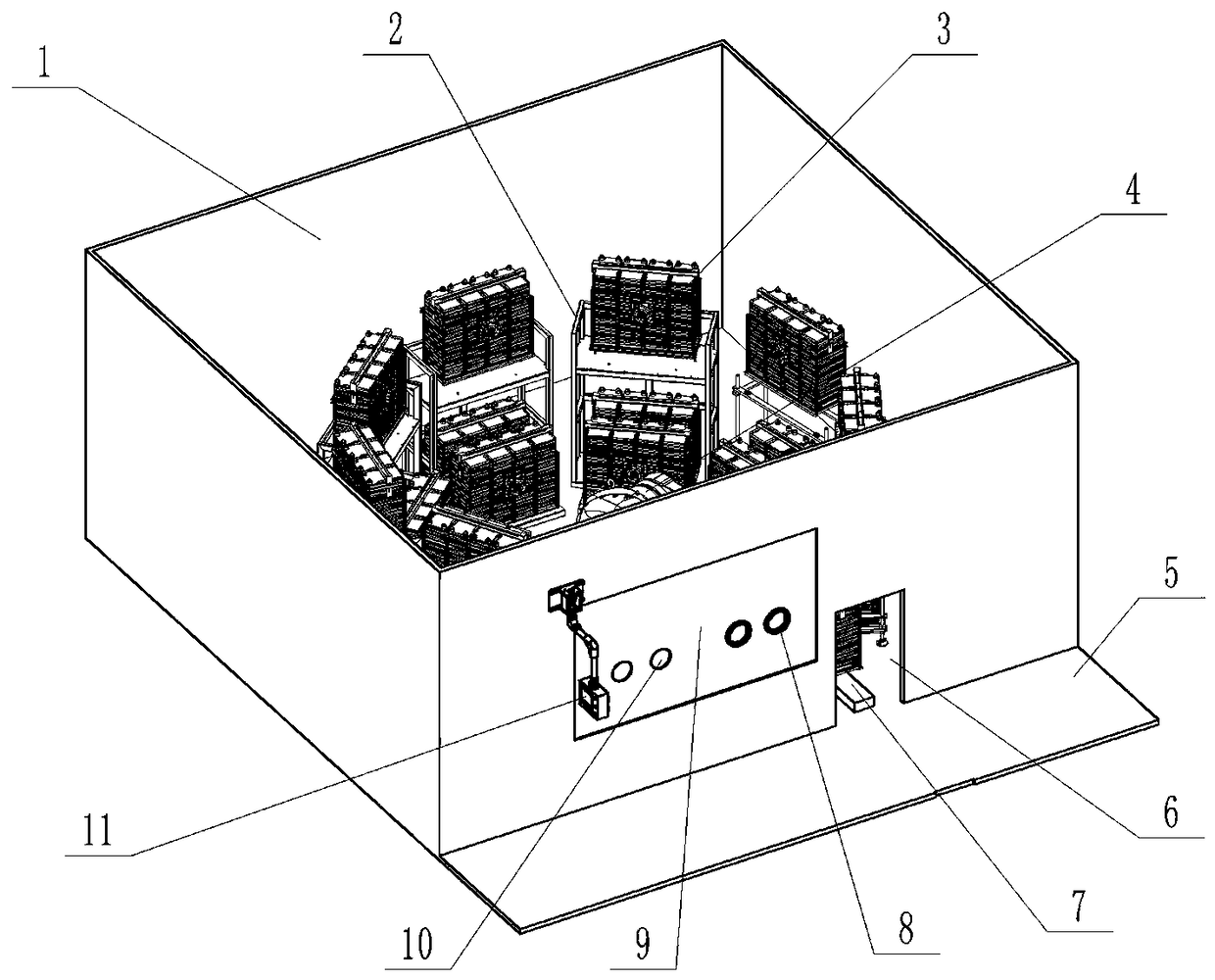

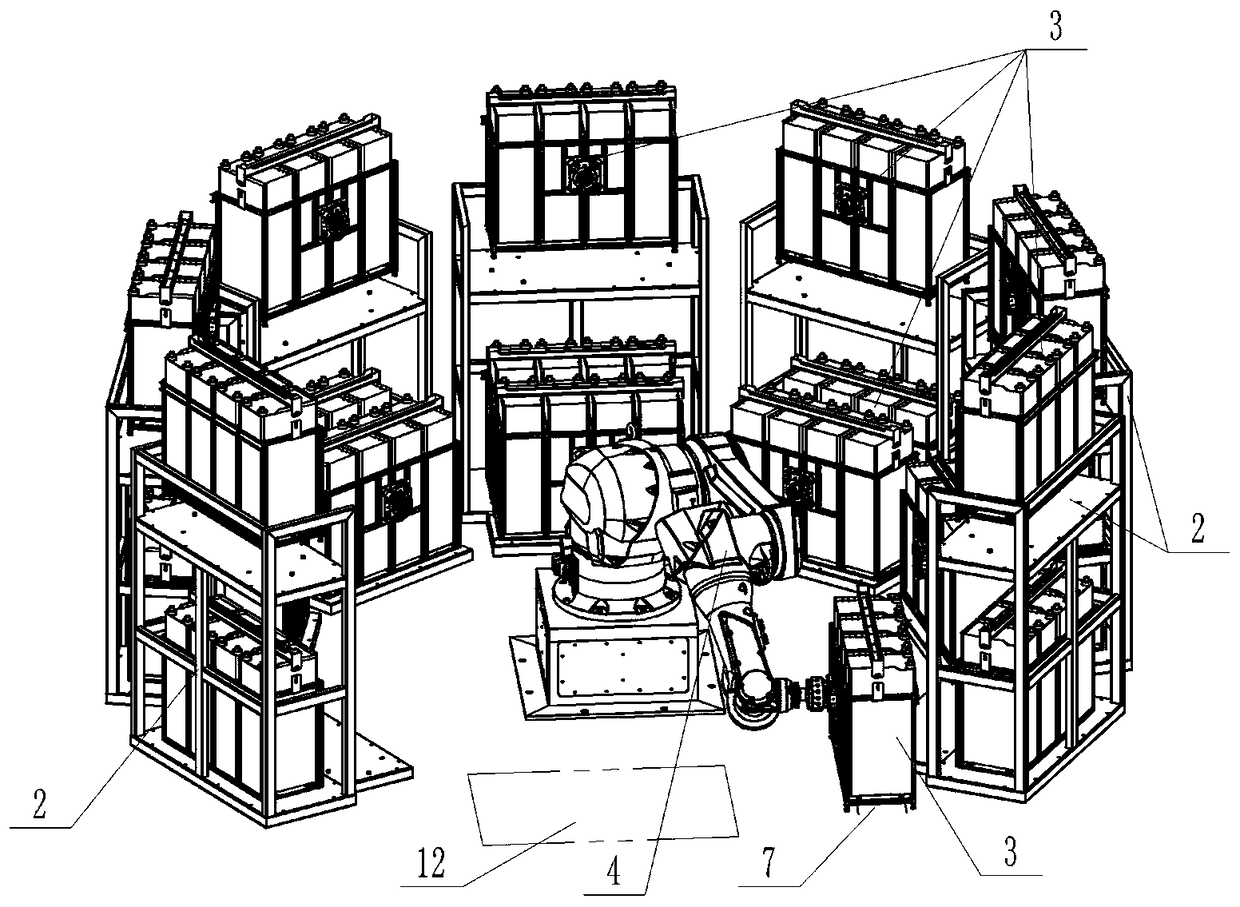

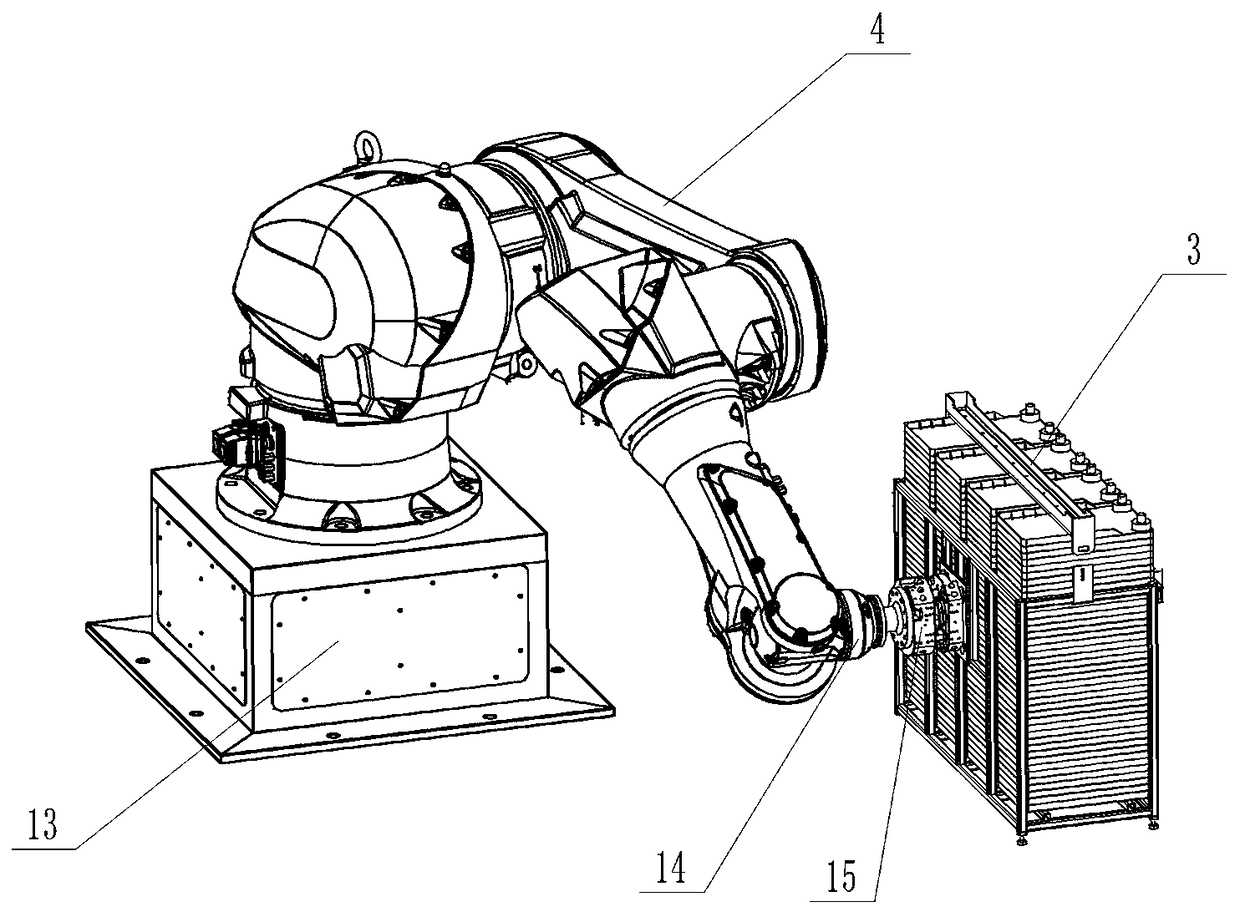

[0028] according to Figure 1-9The specific steps of the present invention are described in detail. The multi-axis robot is applied to the method of preparing biological products in cell factories (taking cell digestion and harvesting as an example), including but not limited to the following steps:

[0029] Step 1. In the constant temperature chamber 1 for the preparation of biological products, several groups of culture racks 2 arranged in a fan shape are set up, and each culture rack 2 is respectively equipped with 1 to 4 sets of cell factory frames 3 . The cell factory frame 3 is composed of a frame main body 16, and the frame main body 16 is provided with four groups of vertical cavities arranged side by side for placing the cell factory 19. The upper end of the vertical cavity is provided with a placement opening, and the cell factory 19 passes through each vertical cavity. The placement opening at the upper end is put into the cell factory frame 3 . The top of the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com