Automatic square tube feeding and servo locating mechanism

A technology of servo positioning and automatic feeding, applied to conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as poor positioning accuracy, achieve the effect of liberating labor, improving positioning accuracy, and realizing automation

Active Publication Date: 2019-01-22

江苏众利达自动化设备有限公司

View PDF6 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For the processing of long workpieces, hydraulic positioning is often used, but the existing servo positioning method, relying on repeated positioning, will produce cumulative errors and poor positioning accuracy

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

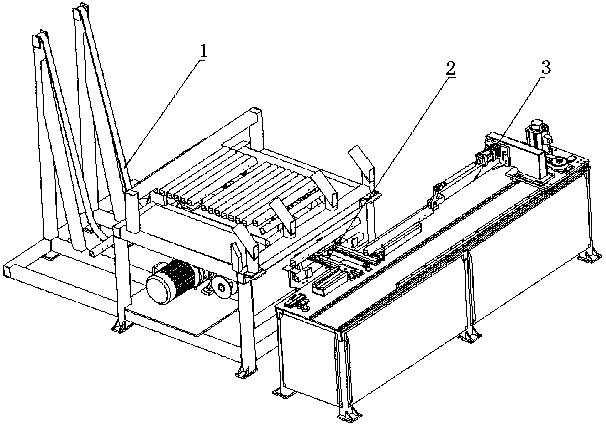

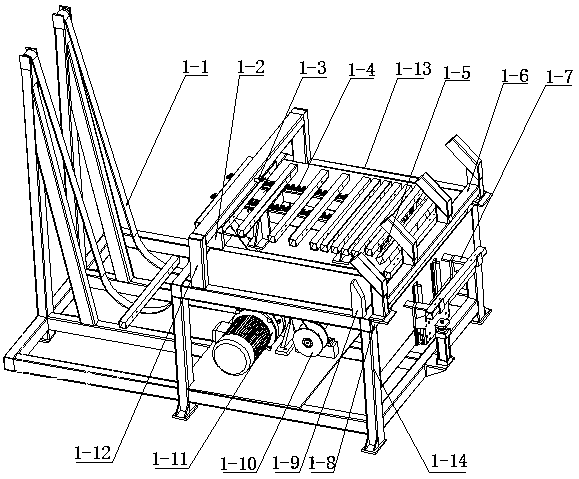

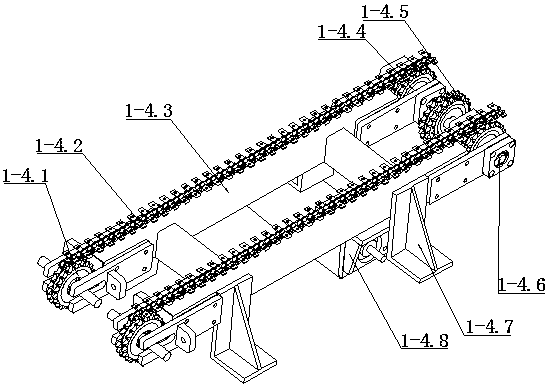

The invention discloses an automatic square tube feeding and servo locating mechanism, and belongs to the technical field of machining automation. The automatic square tube feeding and servo locatingmechanism comprises an automatic square tube feeding mechanism, a servo locating mechanism and a material transferring mechanism. When a hoisting mechanism works, a lifting rope starts to rise, workpieces are driven to ascend, and the workpiece fall onto a chain conveying mechanism through the gravity action. When the workpieces advance one by one along the chain conveying mechanism, after the workpiece advance to a certain position, the workpiece fall along with a guide plate, and are vertically placed under the action of a rear blocking frame. The vertically placed workpieces are pushed by apush air cylinder, and the workpieces are smoothly transferred to a lifting receiving mechanism. After the lifting receiving mechanism receives the workpieces, the workpieces are placed on the material transferring mechanism. The workpieces are transferred to the servo locating mechanism through the material conveying mechanism. The automatic square tube feeding and servo locating mechanism achieves an automatic square tube feeding function and can achieve a servo feeding function on the workpieces, and the locating precision of the workpieces is improved. Automation of square tube machiningis achieved, and labor force is freed up.

Description

technical field The invention relates to the technical field of mechanical processing automation, in particular to an automatic feeding and servo positioning mechanism for square tubes. Background technique With the continuous development of the economy, the call for the liberation of the labor force is getting louder and louder. In the field of mechanical processing, the degree of automation is required to be higher and higher. For the processing of profiles (square tubes, round tubes), the automatic feeding technology for round tubes is relatively mature, while for square tube processing, the automatic feeding technology is obviously lagging behind. For the processing of long workpieces, hydraulic positioning is often used, but the existing servo positioning method relies on repeated positioning, which will generate cumulative errors and poor positioning accuracy. Contents of the invention In order to solve the above technical problems, the present invention provides ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B65G47/82B65G47/24B65G47/28B65G17/46B65G21/20

CPCB65G17/46B65G21/2063B65G47/24B65G47/28B65G47/82B65G2201/0217

Inventor 邵先雨武月超晁岱卫晁岱庆

Owner 江苏众利达自动化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com