Toothpaste tube

A toothpaste tube and tube body technology, applied in the field of toothpaste tubes, can solve the problems of paste residue, paste migration, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

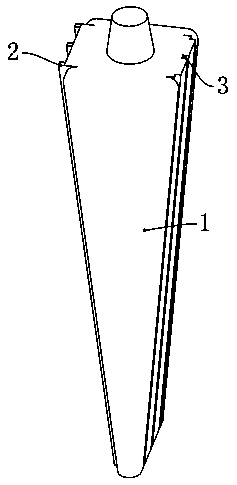

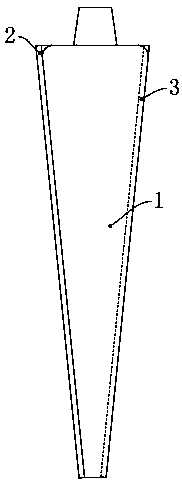

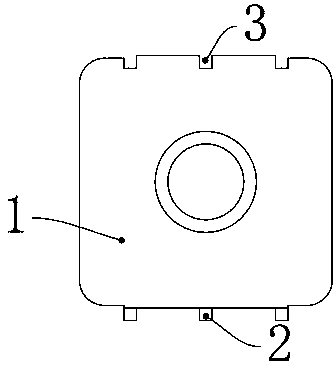

[0012] Such as Figure 1 to Figure 4 As shown, the toothpaste tube of the present invention includes a tube body 1, the top of the tube body 1 is provided with an extrusion port and a cover screwed to the extrusion port, the tube body 1 is surrounded by six walls, and the tube body 1 shrinks gradually from top to bottom Make the side face into an inverted triangle; the front length direction of the tube body 1 is provided with a clamping strip 2, and the backside length direction of the tube body 1 is provided with a clamping groove 3, and the clamping strip 2 corresponds to the position of the clamping groove 3. When the tube body 1 is subjected to When the force is curled from bottom to top, the clip strip 2 can be clipped into the clip slot 3; the pipe wall is formed by tight pressing of inner, middle and outer layers, the inner and outer layers are PE plastic layer 4, and the middle layer is a wire mesh layer 5.

[0013] The working principle of the above technical soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com