Tobacco beetles raising device and raising method using the device

A technology of tobacco beetle and feed, applied in the direction of animal husbandry and other directions, can solve the problems such as the inability to realize the mass feeding of tobacco beetle, the influence of in-depth research on tobacco beetle, the complexity of the feeding device, etc. Guarantee the effect of eclosion adult rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

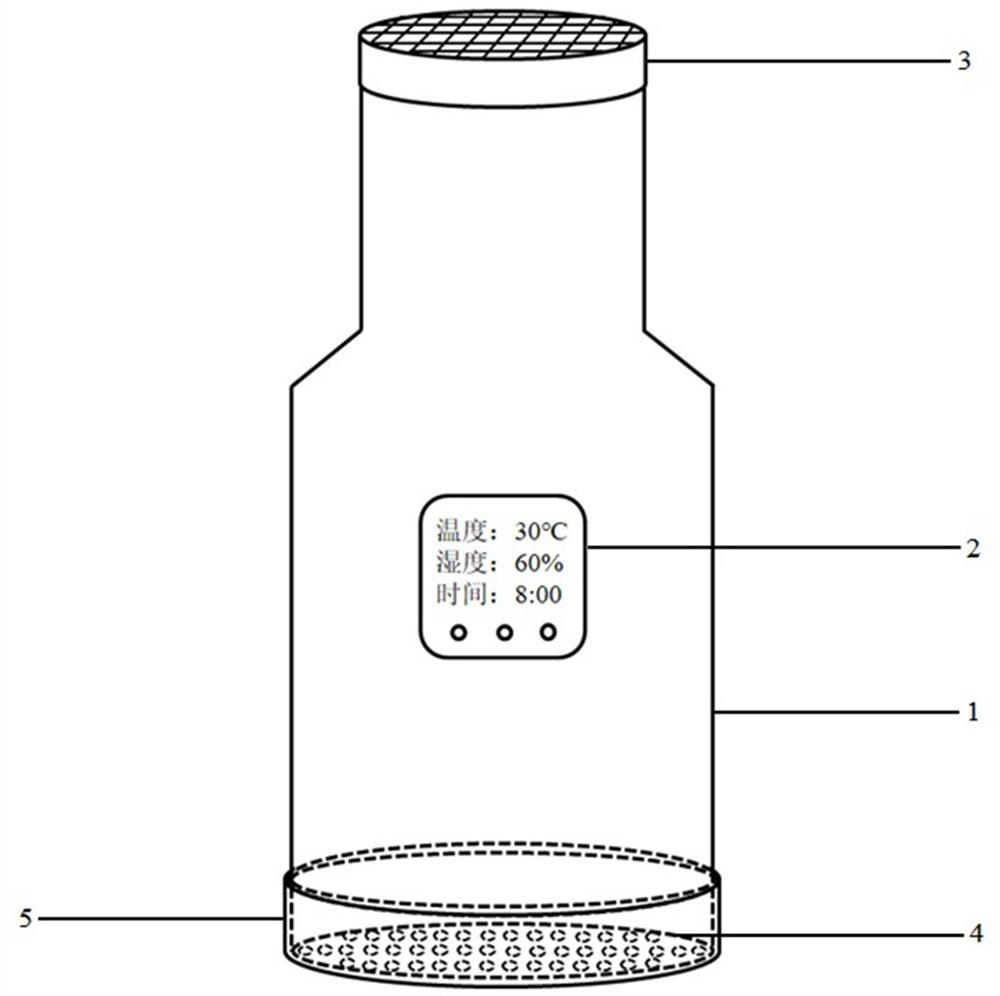

[0034] Such as figure 1 As shown, the Tobacco A breeding device provided by the application has a structural main body of a columnar rearing bottle 1; the rearing bottle 1 is prepared from a transparent material (specifically, resin, glass or acrylic, etc.); the middle part of the bottle body of the rearing bottle 1 A monitoring and display device 2 is provided for real-time measurement and display of the temperature and humidity inside the breeding bottle;

[0035] The top of the feeding bottle 1 is provided with a mesh type ventilating bottle cap 3, and the aperture of the mesh should not exceed 1.5 mm, so as to prevent the tobacco A from escaping; The mouth of the bottle, so as to realize the sealing of the mouth of the breeding bottle;

[0036] The bottom of the bottle body of the feeding bottle 1 is a double-layer bottom cover structure, and the inner bottom cover 4 can be movable or fixedly arranged on the bottom of the feeding bottle body, and the bottom of the inner ...

Embodiment 2

[0039] Utilizing the tobacco beetles breeding and separating device described in Example 1, the inventors carried out the actual raising of tobacco beetles and the separation of male and female adults. The specific process is briefly described as follows.

[0040] (1) Tobacco beetle hatching

[0041] First, put a proper amount of tobacco beetle eggs on the inner bottom cover of the bottom of the feeding bottle of the tobacco beetle breeding device, and hatch at a temperature of 30-32°C and a humidity of 70%; the hatching time is about 6 days until all the eggs become larvae.

[0042] It should be noted that, during the hatching process, the inventor made statistics on the time of hatching into larvae at different hatching temperatures, specifically:

[0043]When the humidity is controlled at 70%, different incubation temperatures have certain effects on the hatching time of eggs. It takes about 310 h to hatch at 22°C; about 270 h at 24°C; about 223 h at 26°C; 28 It takes abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com