A production scheduling method with multi-rule constraints

A production scheduling and rule-constrained technology, applied in the direction of instruments, manufacturing computing systems, data processing applications, etc., can solve the problems of frequent changes in painting colors, unbalanced production load, and increased costs in the painting workshop, and achieve the goal of solving the load of the assembly workshop Effects of unevenness, improvement of production efficiency, and reduction of frequency of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples of implementation.

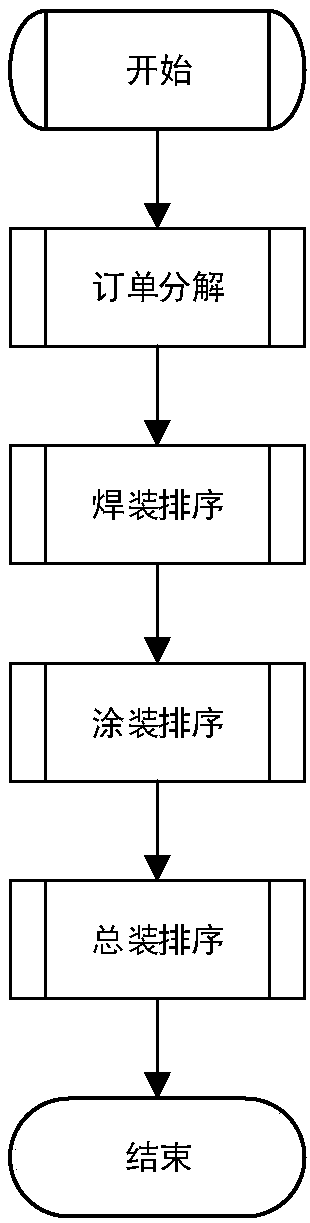

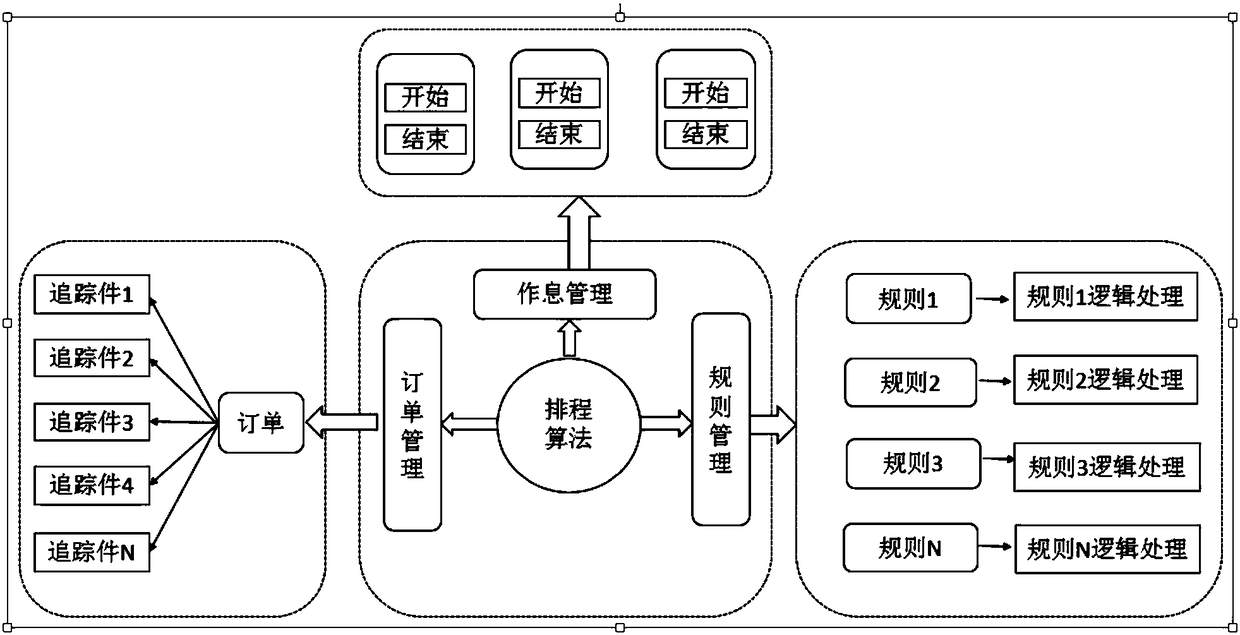

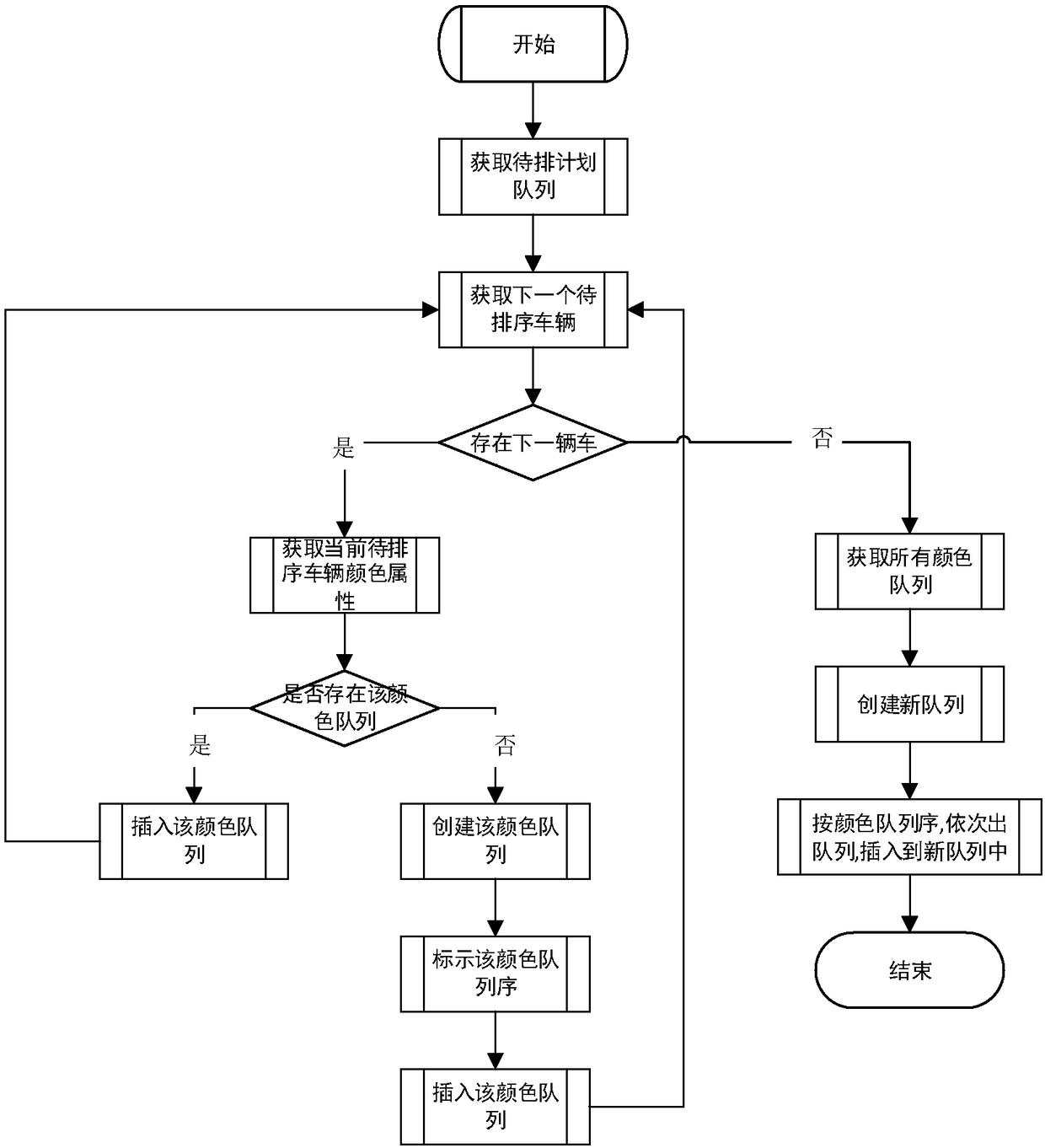

[0042] Such as Figure 1-Figure 2 As shown, a multi-rule-constrained production schedule is specifically aimed at the vehicle industry, where multiple varieties are produced on the same line. Sort the problem. Include the following steps:

[0043] Step 1: Initialize the constraints that affect production scheduling as a rule set composed of a series of production rules, expressed as where R i Production rules are divided into the following types: delivery date priority rules, color concentration rules, color distribution rules, model concentration rules, model distribution rules, high, medium and low configuration distribution rules, engine concentration rules, engine distribution rules, gearbox concentration Rules, gearbox distribution rules, load balancing rules, logistics consumption leveling rules;

[0044] Step 2: Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com