Electric tailgate support bar application simulation test method

A simulation test and support rod technology, which is applied in design optimization/simulation, special data processing applications, electrical digital data processing, etc., can solve problems affecting the mechanical performance of the tailgate mechanism and unreliable hovering of the tailgate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that the following examples are based on the premise of this technical solution, and provide detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

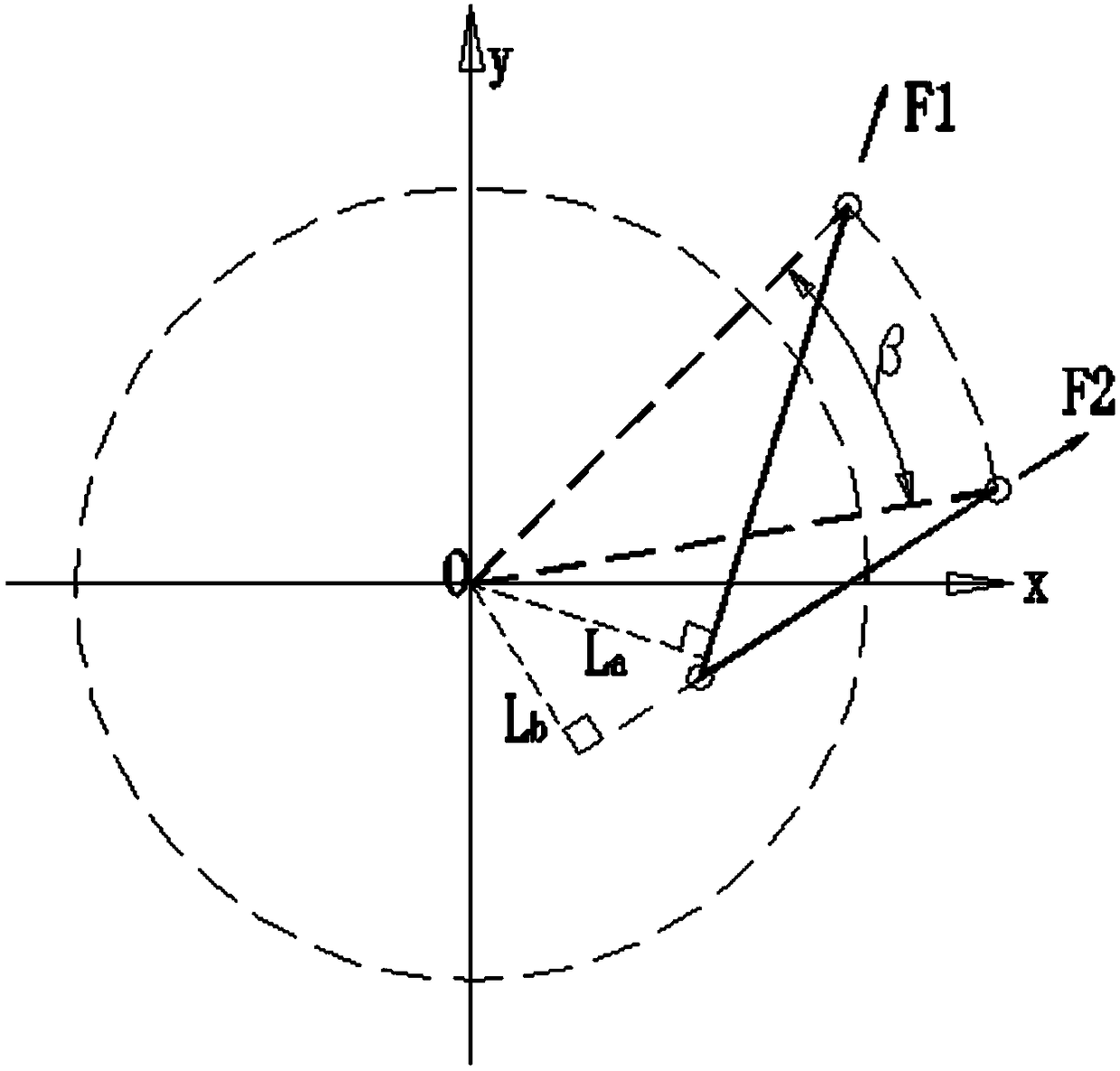

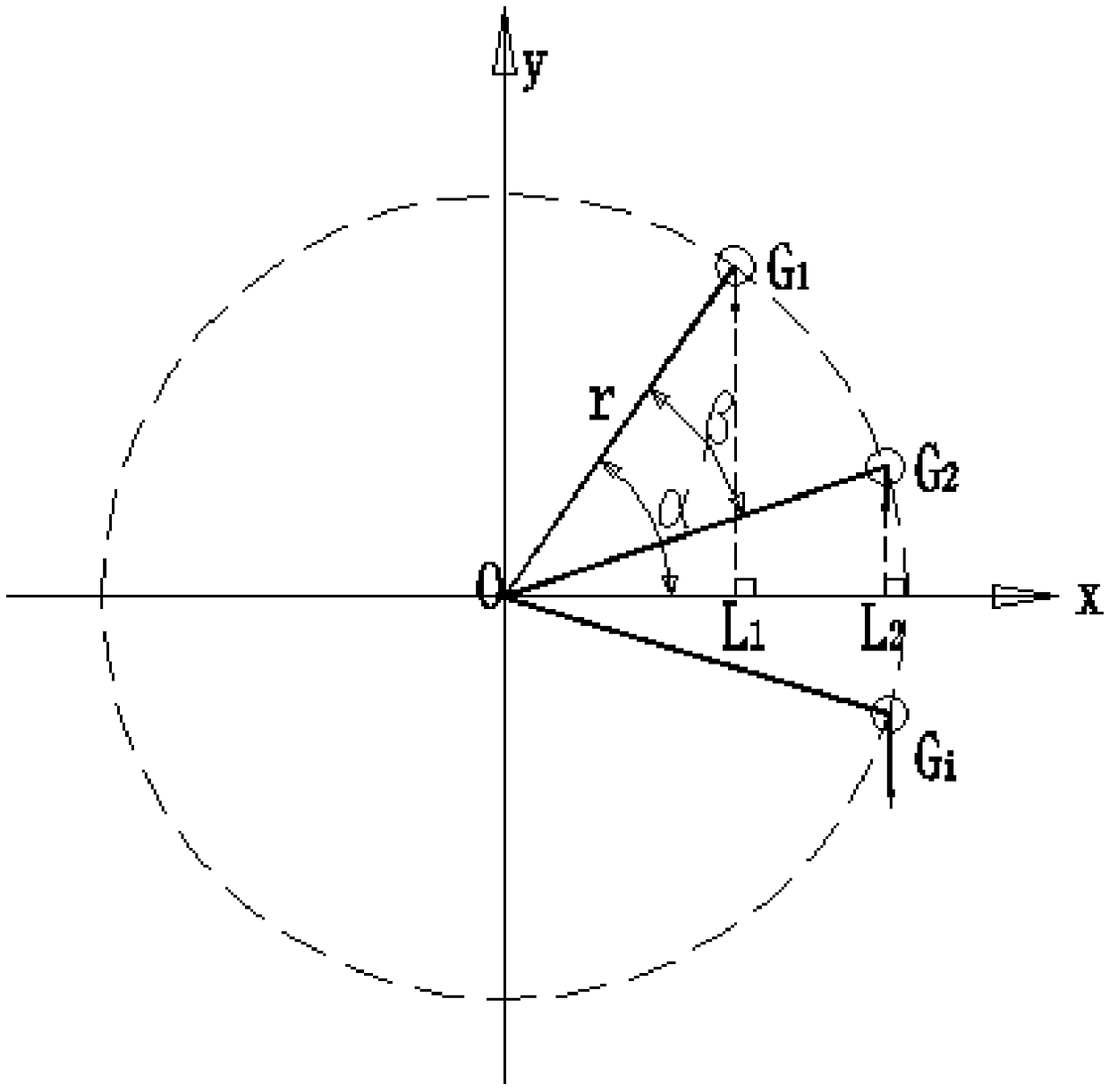

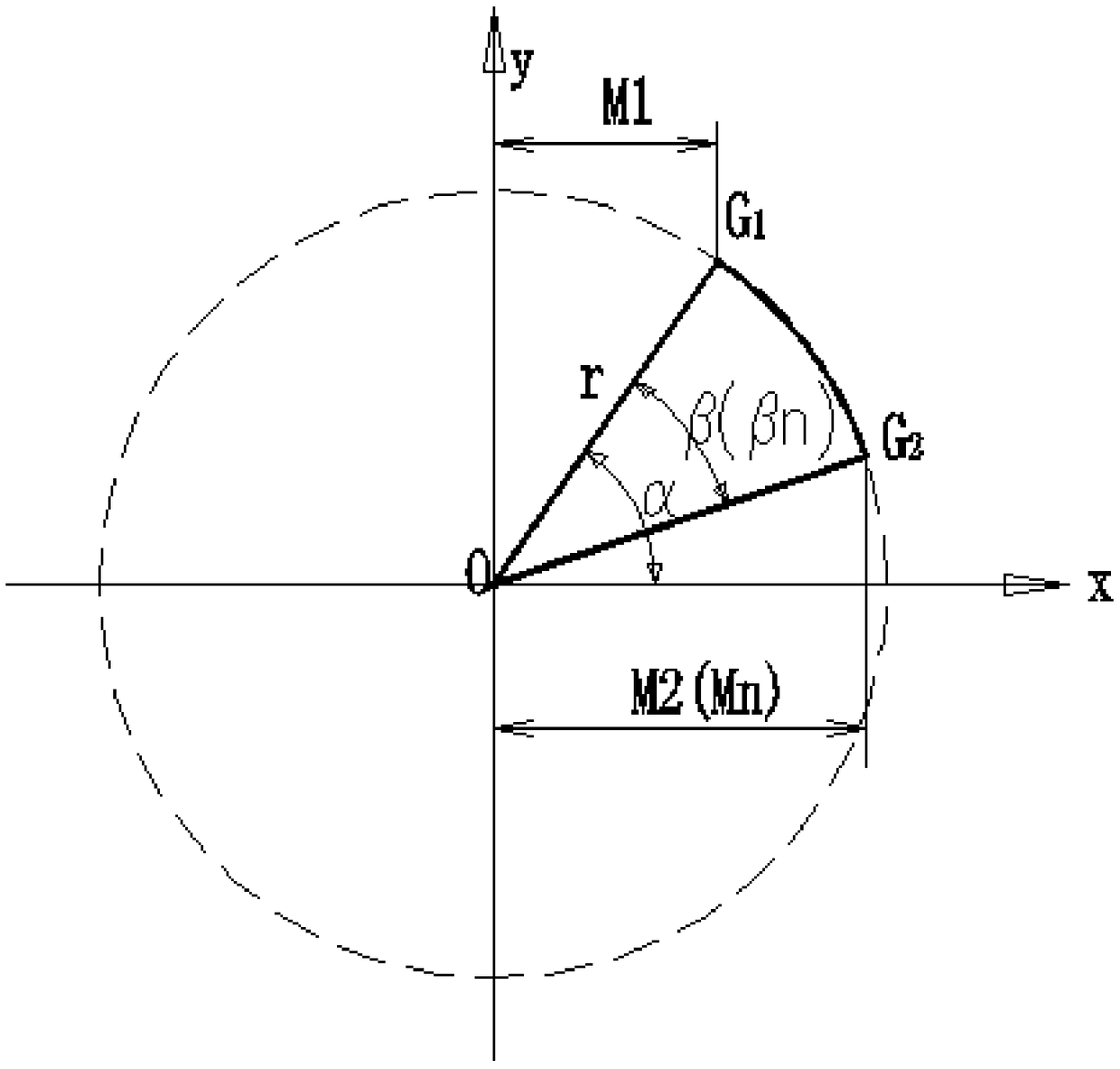

[0017] A device for the application simulation test of the electric tailgate support rod, including an electric tailgate, a fixed bracket and a support rod, the support rod is set on the electric tailgate through the fixed bracket, and also includes a copying device and a support rod dynamometer, and the copying The device communicates with the pole dynamometer, and the copying device is used to copy the shape of the electric tailgate and the support pole and transmit the data to the pole dynamometer, and the pole dynamometer is used to read the shape of the electric tailgate and the support pole. The shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com