A Portable Automatic Clamping Device for Nonlinear Ultrasonic Testing

A non-linear ultrasonic and clamping device technology, which is applied to measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves to analyze materials, etc. Explain in detail the probe clamping device and other issues to achieve the effects of strong applicability, stability assurance, and convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

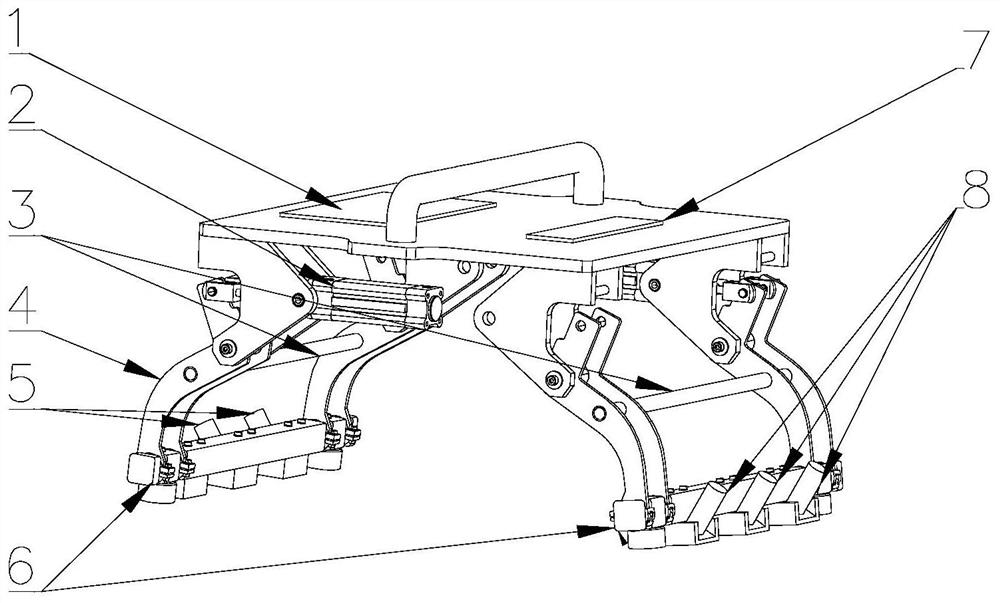

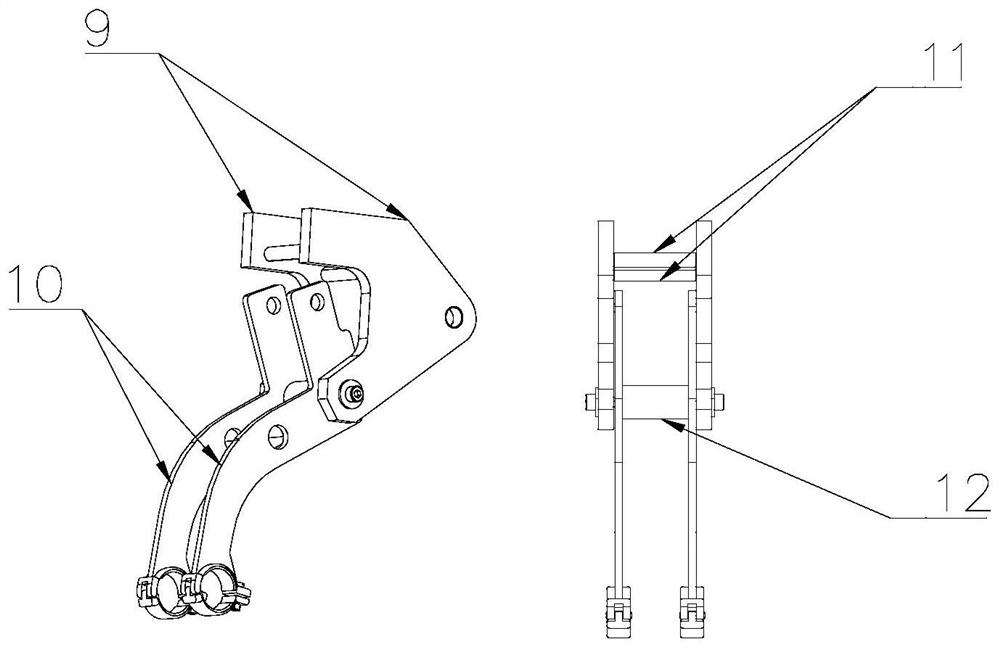

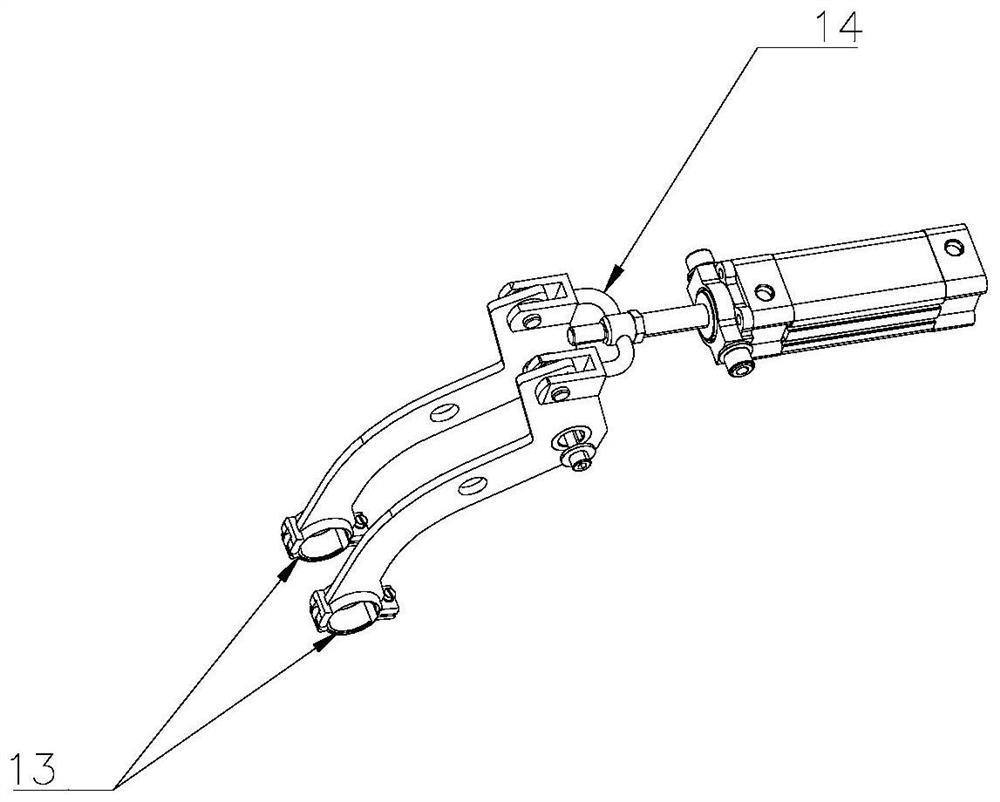

[0021] like figure 1 As shown, a portable automatic clamping device for nonlinear ultrasonic testing, including: mechanical claw assembly, display screen, controller, small stepper motor, electromagnet, pressure sensor, square connecting rod, wedge, ultrasonic excitation Transducer, ultrasonic receiving transducer, a handle is installed in the middle of the top plate of the device, which is used for portability of the device, combined with figure 2 As shown, the mechanical jaw assembly includes: a splint, a jaw plate, a U-shaped threaded connector, a tensionable ring buckle, a short cylindrical connecting rod, and a sleeve. Two splints 9 are connected side by side with two short cylindrical connecting rods 11, two clamping jaw plates 10 are connected with two clamping plates 9 with stud screws, and sleeve 12 is housed between two clamping jaw plates 10. The mechanical ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com