Hanging basket lifting equipment

A hanging basket and equipment technology, applied in the direction of housing structure support, housing structure support, scaffolding supported by housing structure, etc., can solve the problems of inapplicability for internal use of buildings and the inability of equipment to be used flexibly, and achieve stable winding or unwinding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

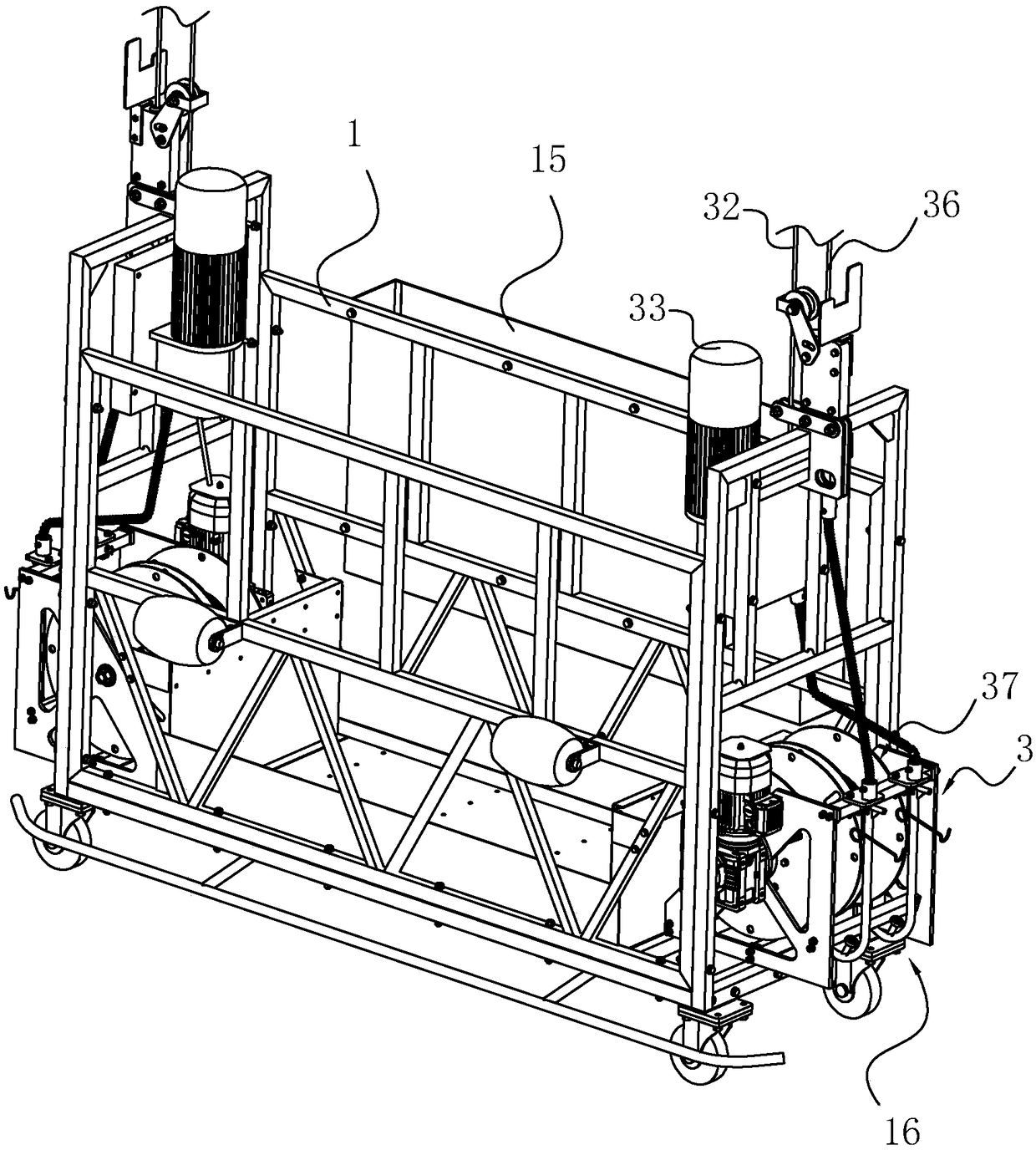

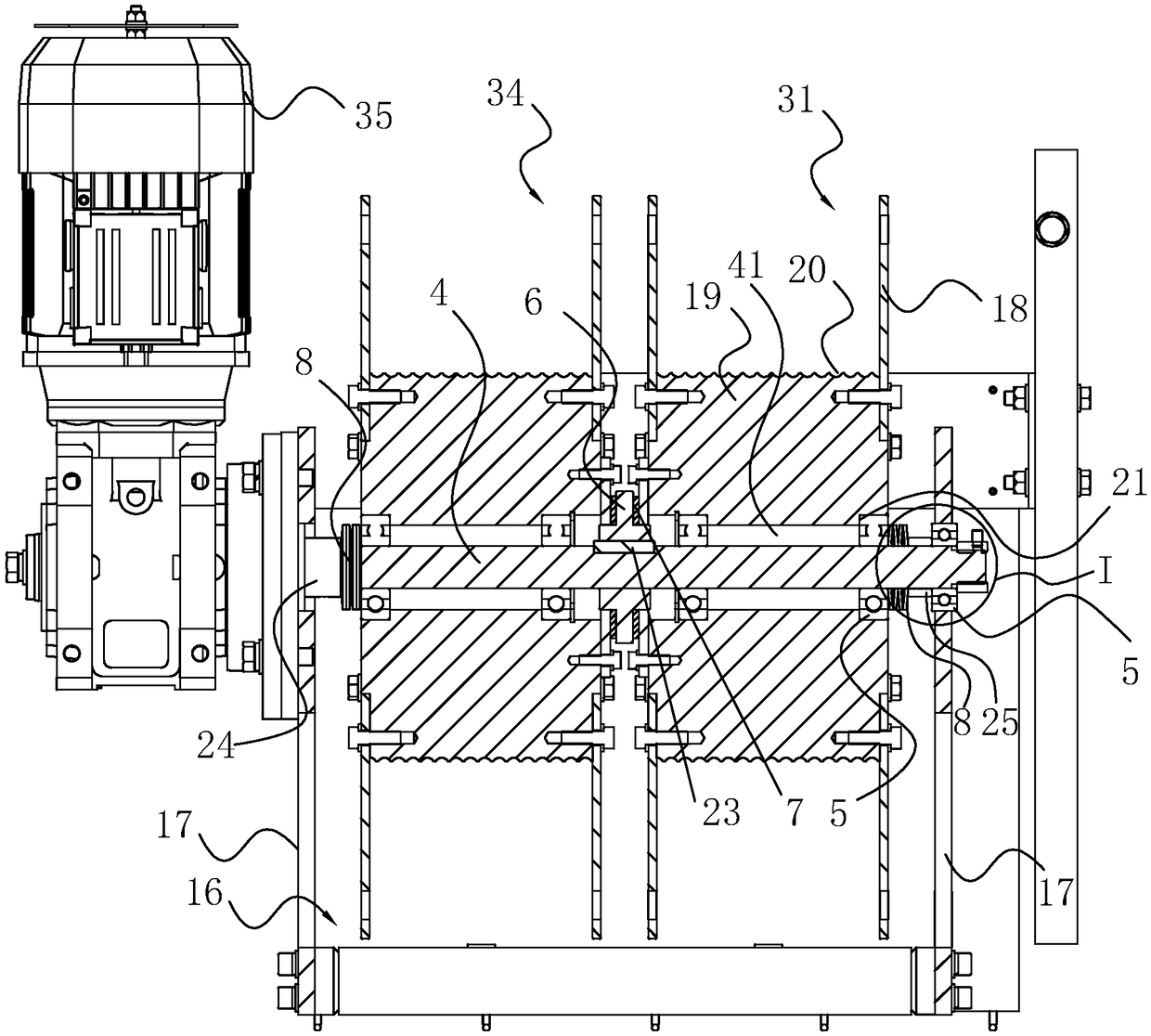

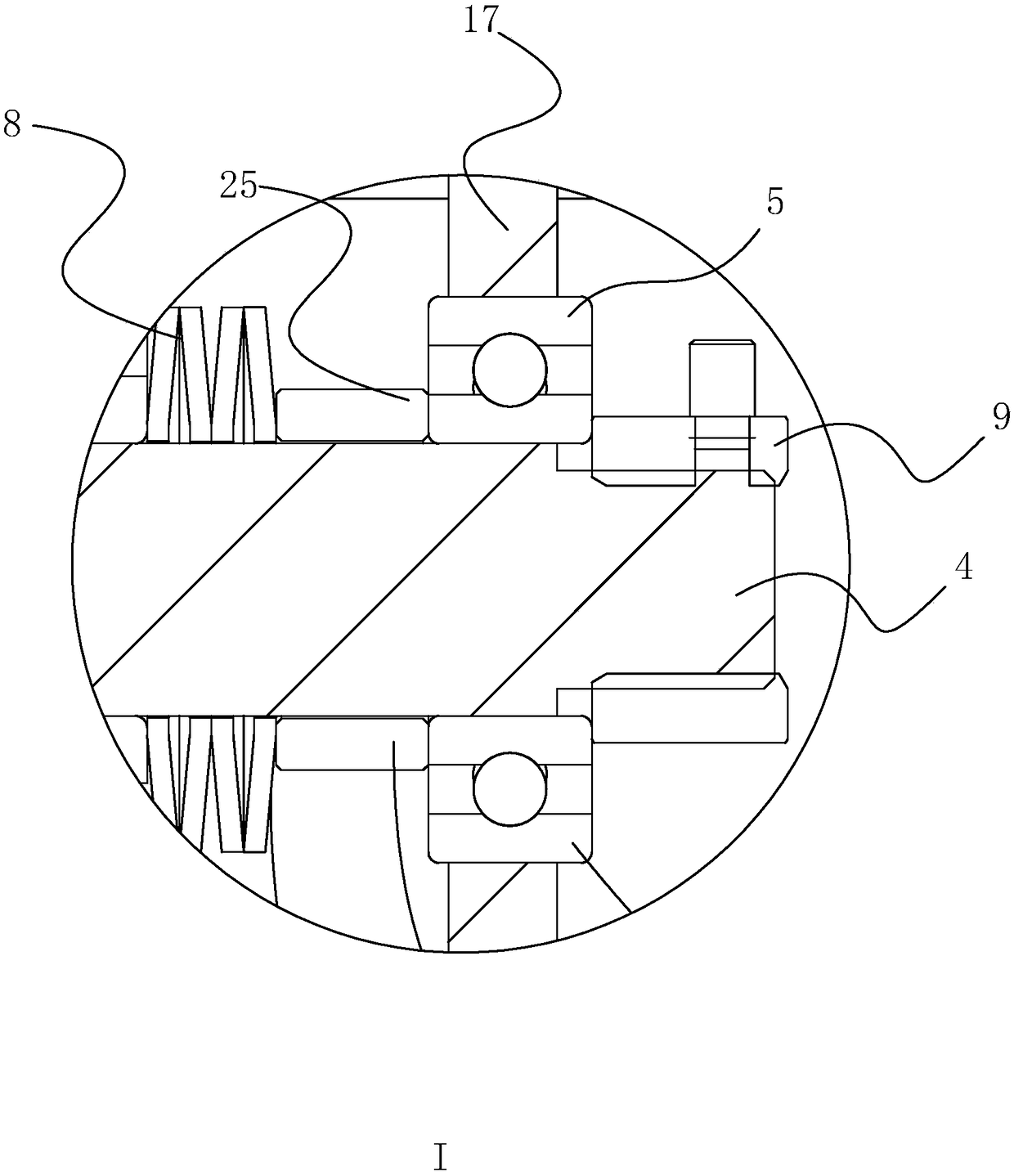

[0037] A lifting basket equipment, refer to figure 1 As shown, it includes a hanging basket 1 for standing operators. A group of cable mechanisms 3 are respectively arranged on both sides of the hanging basket 1 in the length direction. The cable mechanism 3 includes a winding device 37 and a main cable connected to the winding device 37. 32 and the lifting motor 33 that is fixed on the hanging basket 1 and is used to promote the main cable 32, the main cable 32 extends vertically upwards to the top track 2 fixed on the building (marked on Figure 4 ), the upper end of the main cable 32 is fixedly connected to the top rail 2. During use, the main cable 32 is rewound or unrolled by the traction of the lifting motor 33 and the winding device 37, so as to realize the lifting of the entire hanging basket 1 .

[0038] The hanging basket 1 has a cuboid upper opening structure as a whole. On the side wall of the hanging basket 1 facing away from the wall, a control box 15 for contro...

Embodiment 2

[0049] A lifting basket, the difference from the first embodiment is that refer to Figure 5 As shown in the figure, because different buildings have different structures, according to the use requirements of different buildings, the top rail 2 can be changed according to the actual use situation, and it can be made into a straight line or an arc shape. The connection between straight lines and arcs can also be made, and the top rail 2 is provided with a chute 38 with a T-shaped cross-section, and the mounting seats 14 corresponding to the cable mechanisms 3 on both sides are slidably connected in the chute 38. The mounting seats 14 use The rollers (not shown) are rollingly connected to the chute 38, and the drive motor 40 is fixedly installed on the mounting base 14. The mounting base 14 is fixedly connected to the upper ends of the main cable 32 and the auxiliary cable 36, and the drive motor 40 is activated during operation. , using the output shaft of the drive motor 40 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com