Sludge pretreatment device

A pretreatment device and sludge technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problems of high equipment investment and treatment costs, and achieve daily operating costs Low power consumption, low power consumption, convenient maintenance and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

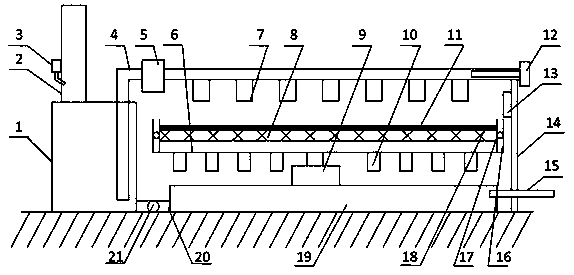

[0019] Such as figure 1 As shown, a sludge pretreatment device includes a sludge settling tank 1 and a drying area 11; the top of the sludge settling tank 1 is provided with a sludge inlet pipe 2 and a sludge outlet pipe 4; the sludge The side of the inlet pipe 2 is provided with a dosing device 3; the sludge outlet pipe 4 extends from the bottom of the sludge settling tank 1 to the top of the drying area 11; the sludge outlet pipe 4 is provided with a delivery pump 5, so that The end of the sludge outlet pipe 4 is provided with a plug 12; the sludge outlet pipe 4 is provided with a mud outlet pipe 7; one side of the sludge outlet pipe 4 is provided with a support rod 14; The mud outlet pipe 7 communicates with the sludge outlet pipe 4; the drying area 11 includes a drying chamber 6, a rotating device 9 and a water accumulation container 19; an activated carbon filter layer 8 is arranged in the drying chamber 6; Both sides of the airing chamber 6 are provided with chutes 16; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com