Overhead arc-shaped slide way type rack traction device

A technology of arc-shaped slideway and traction device, which is applied in the field of dry quenching, can solve the problems of heavy rack box at the end, complex equipment structure, poor running stability, etc., to ensure stability and safety, and reduce power consumption , the effect of increased energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

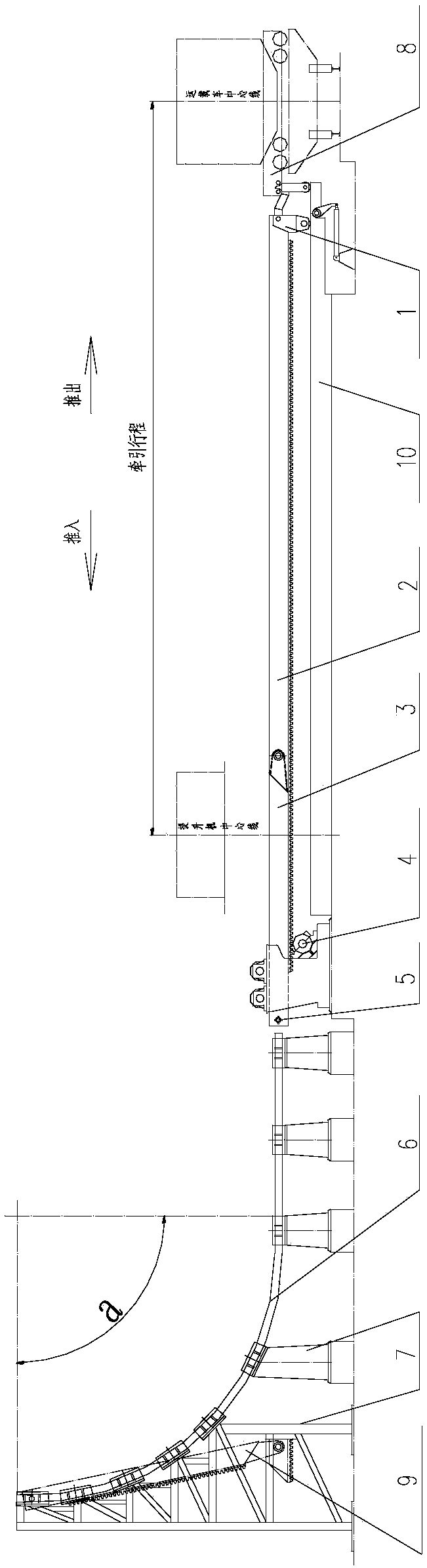

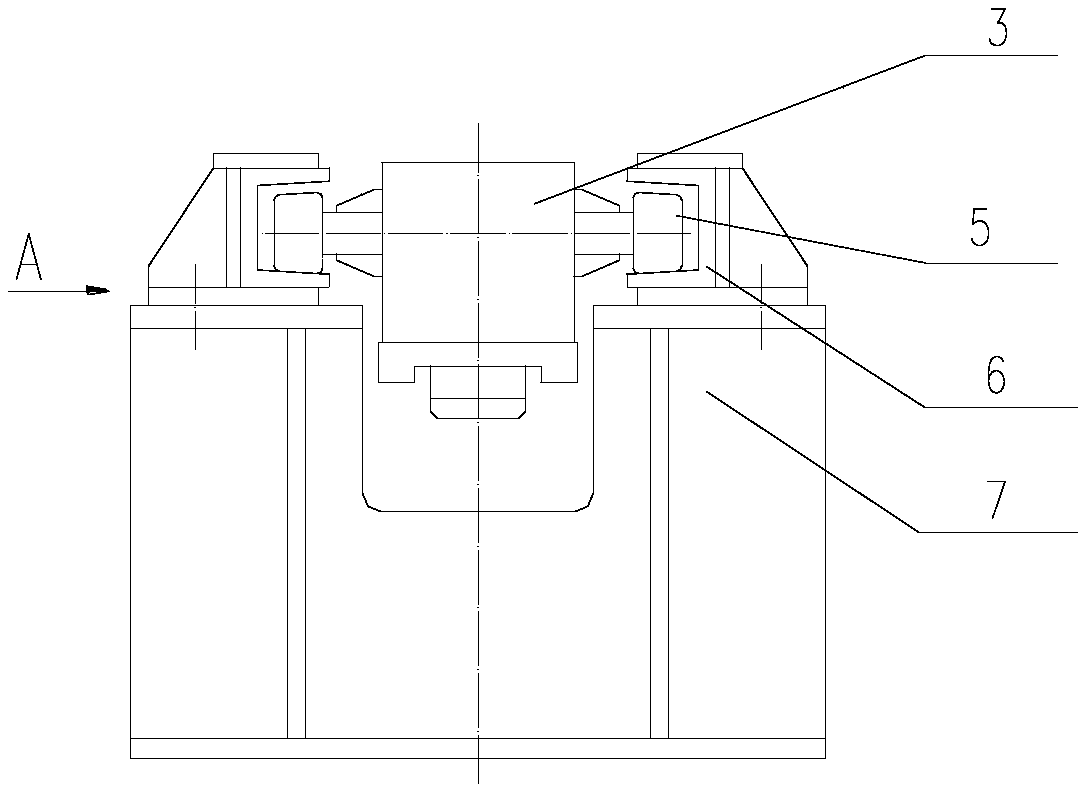

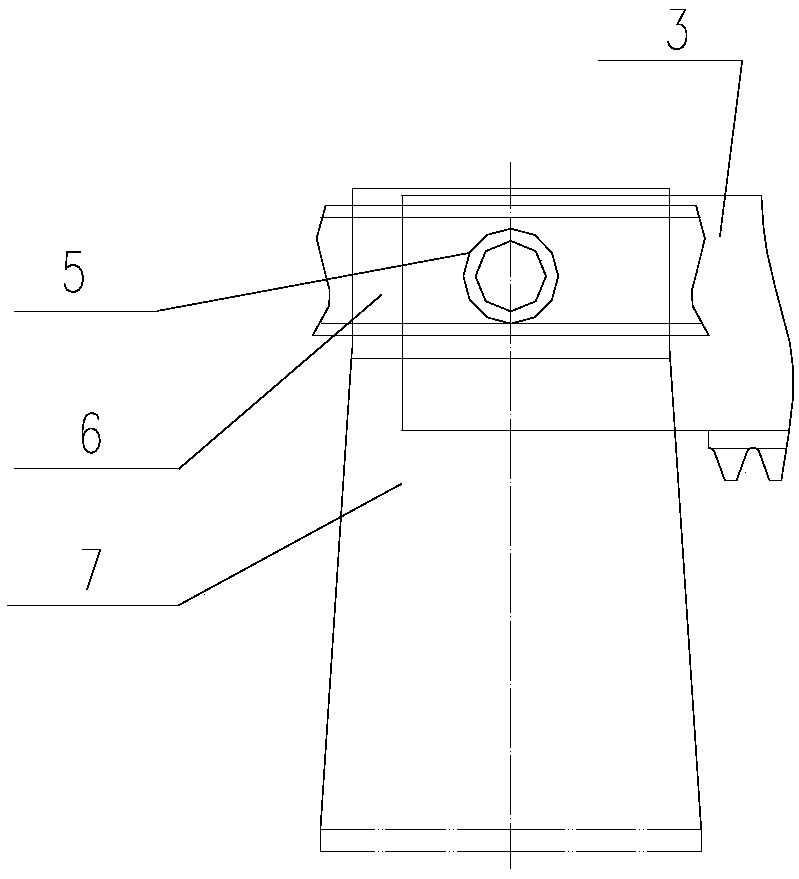

[0023] Such as Figure 1~3 As shown, a kind of aerial arc-shaped slideway type rack traction device according to the present invention includes a front-end trolley 1, a front-end rack box 2, a tail-end rack box 3, a transmission gear 4, a roller 5, and an arc-shaped slideway 6. The bracket 7 and the fixed track 10. The front-end trolley 1 is located on the side of the carrier and can move along the fixed track 10 laid on the ground; one end of the front-end rack box 2 is connected to the front-end trolley 1, and the other end is connected to the tail end The rack box 3 is hinged, the front rack box 2 and the rear end rack box 3 mesh with the transmission gear 4 fixed on the foundation through the support through the rack, and the front rack box 2 and the rear end can be realized under the drive of the driving device. The reciprocating motion of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com