Helicopter power cabin front fairing

A technology for helicopter power and fairing, which is applied in the direction of motor vehicles, rotorcraft, aircraft parts, etc., to achieve the effect of light weight, high efficiency, good installation and maintenance functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

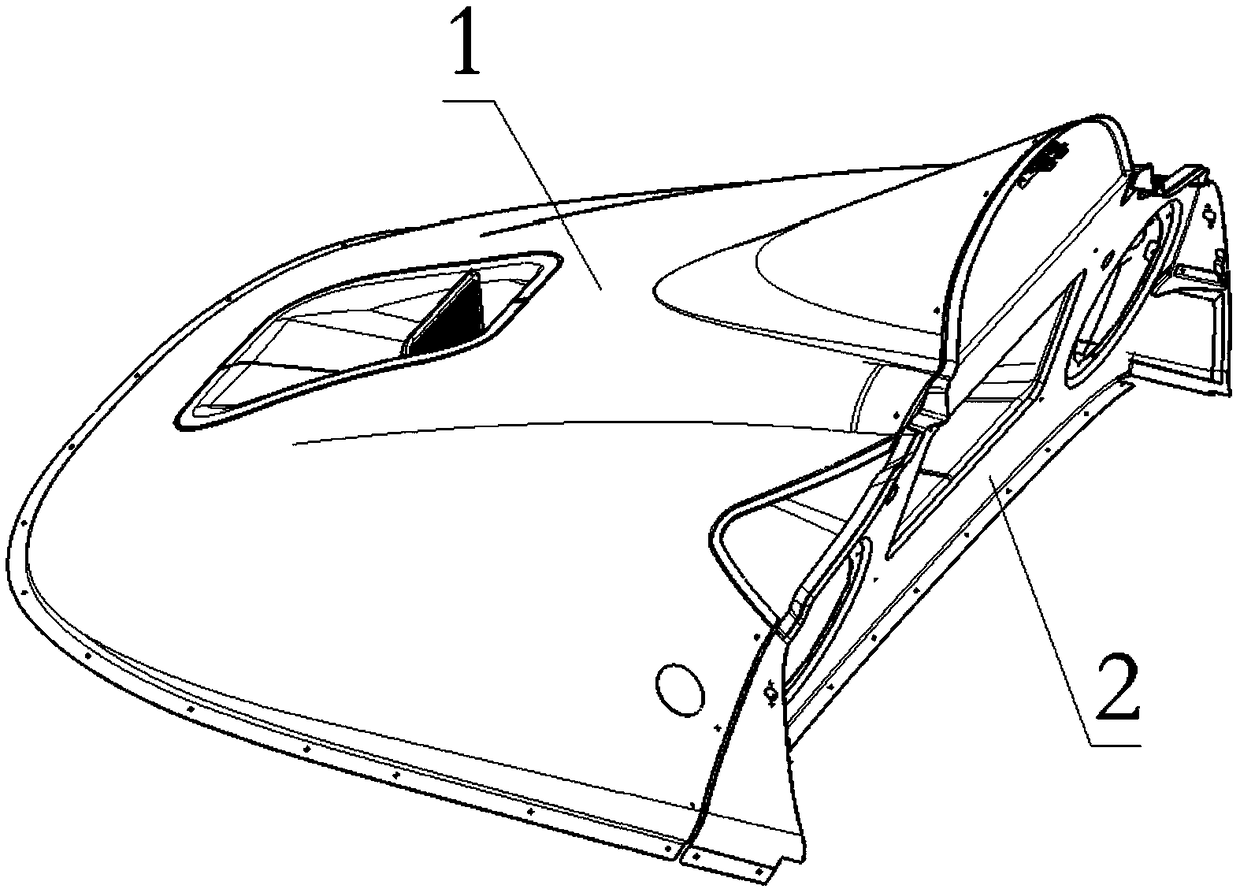

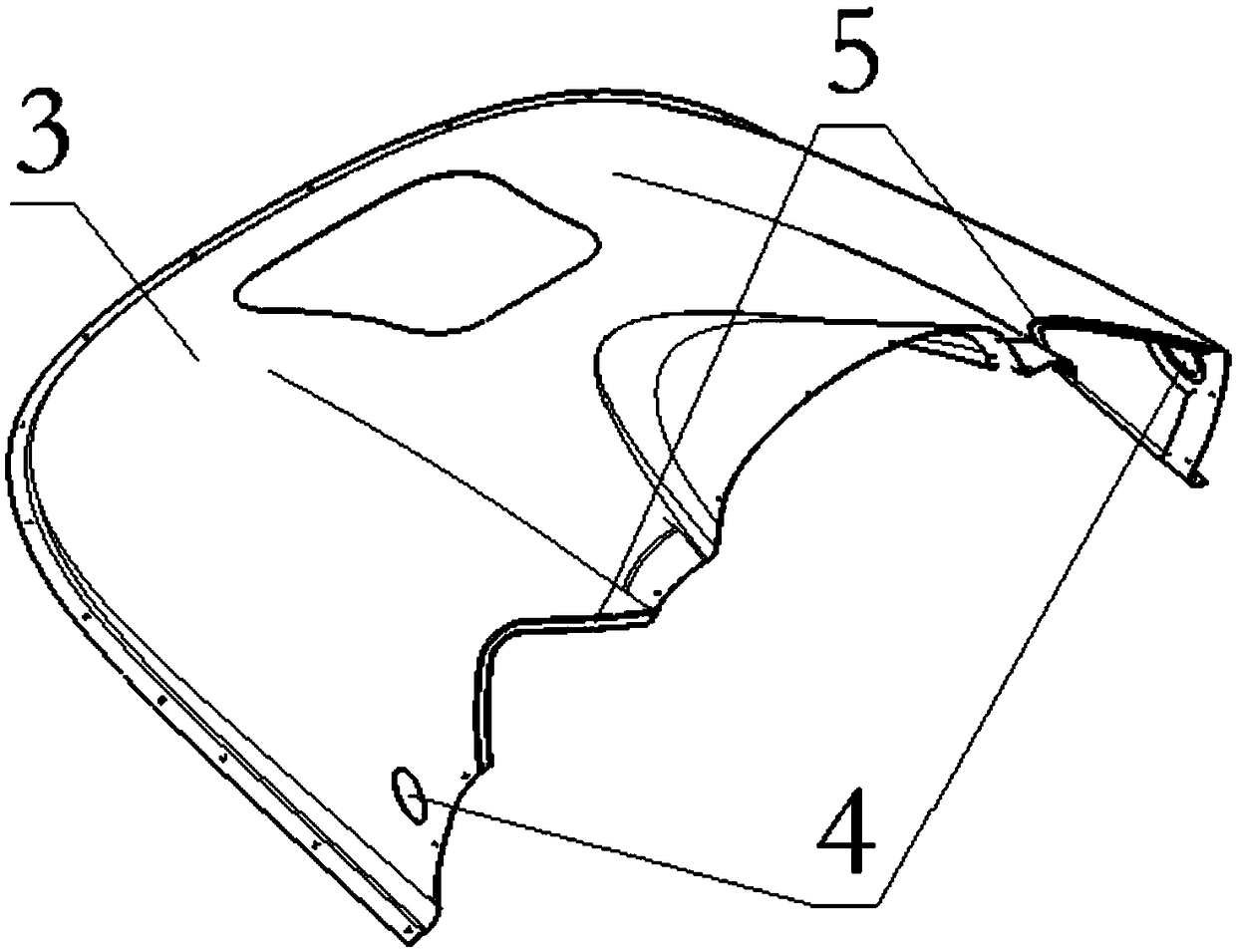

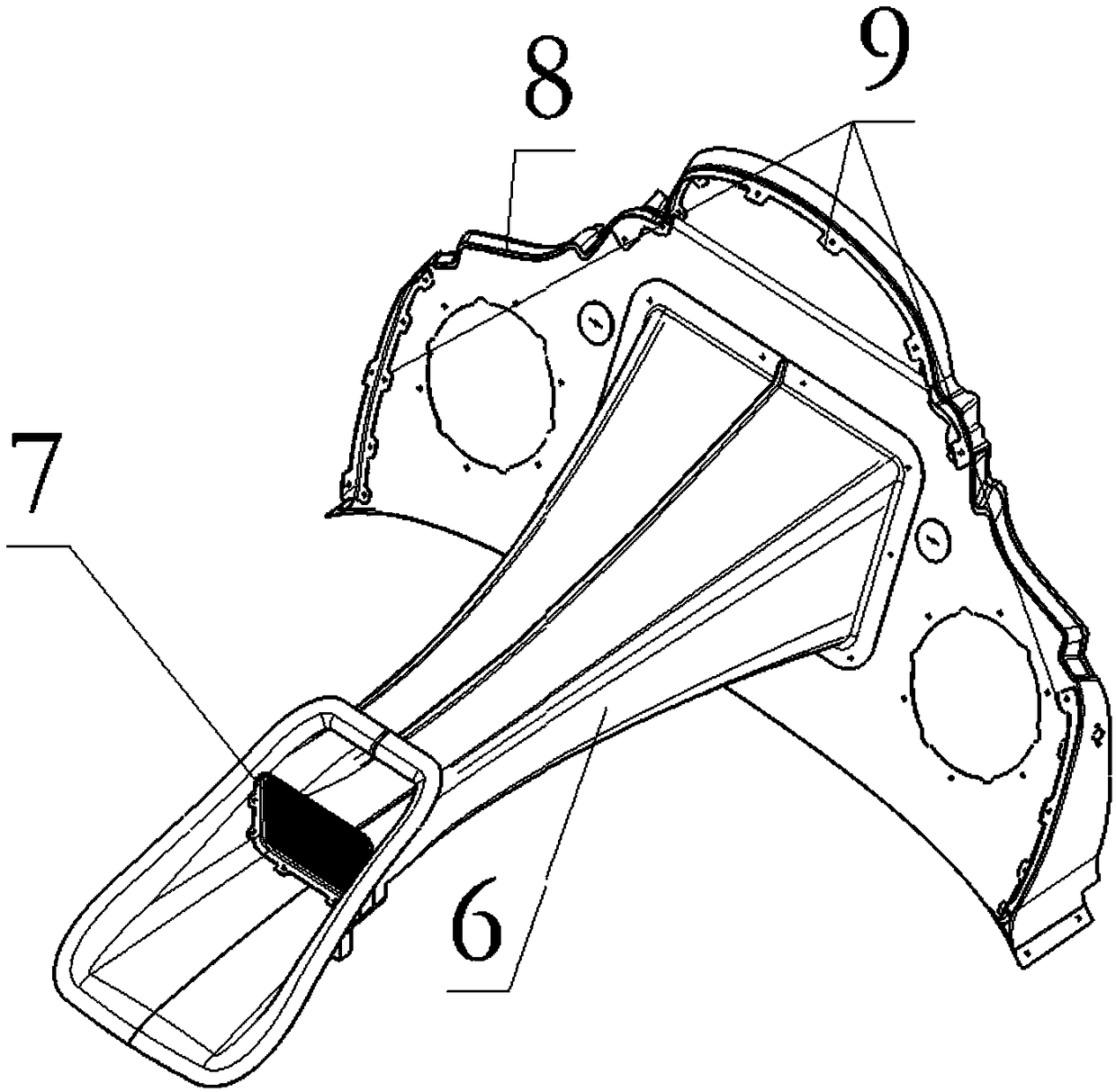

[0017] The invention relates to a front fairing of a helicopter power cabin, which comprises a lubricating oil radiator fairing assembly 1 and an oil radiator inlet passage assembly 2 .

[0018] The lubricating oil radiator fairing assembly 1 is formed by bonding the movable oil radiator fairing 3, the left / right hydraulic observation window 4, and the left / right sealing rubber pad 5; the lubricating oil radiator fairing assembly 1 is connected with the cockpit ceiling and The lubricating oil radiator intake channel assembly 2 is connected with angled material screws, and different diameters are used according to the lengths of the two specifications of the screws, so as to prevent errors in fairing reassembly during maintenance. The active fairing 3 of the lubricating oil radiator is a honeycomb sandwich structure of composite material, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com