A positioning and navigation system and method for an automatic inspection robot in intelligent manufacturing

A technology of intelligent manufacturing and navigation system, applied in manufacturing tools, program control manipulators, manipulators, etc., can solve the problems of parts failure, lack of improvement, easy infiltration of rainwater, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

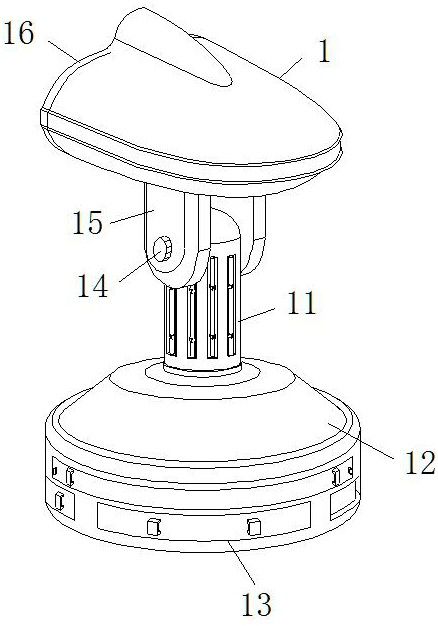

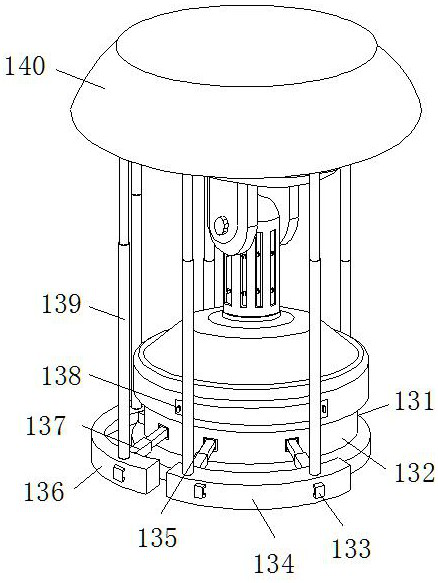

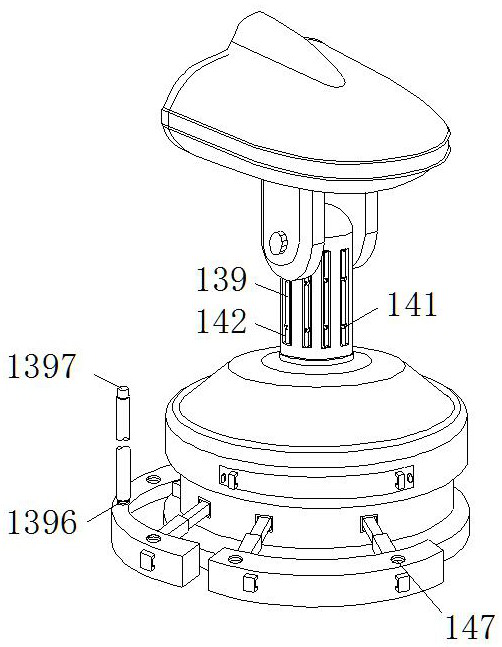

[0035] see Figure 1-7 , the present invention provides the following technical solutions: a positioning and navigation system for an automatic inspection robot in intelligent manufacturing, including an automatic inspection robot 1, and the automatic inspection robot 1 includes a support frame 11, a base 12, a rainproof assembly 13, a limit bolt 14, Connecting frame 15 and automatic inspection robot main body 16, wherein, the below of automatic inspection robot main body 16 is provided with connecting frame 15, and connecting frame 15 is provided with support frame 11 away from the side of automatic inspection robot main body 16, and support frame 11 and connecting frame 15 They are fixedly connected by limit bolts 14, a base 12 is provided under the support frame 11, and a rainproof assembly 13 is partially provided inside the base 12, and the rainproof assembly 13 includes a first fixing plate 131, a first receiving groove 132, a second Two fixing plates 134, the second hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com