Intelligent automatic detecting device for thread missing of bracket

An automatic detection device and intelligent technology, applied in sorting and other directions, can solve problems such as missing internal screw holes, high work intensity, and low efficiency, and achieve the effects of overcoming high work intensity, improving efficiency, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

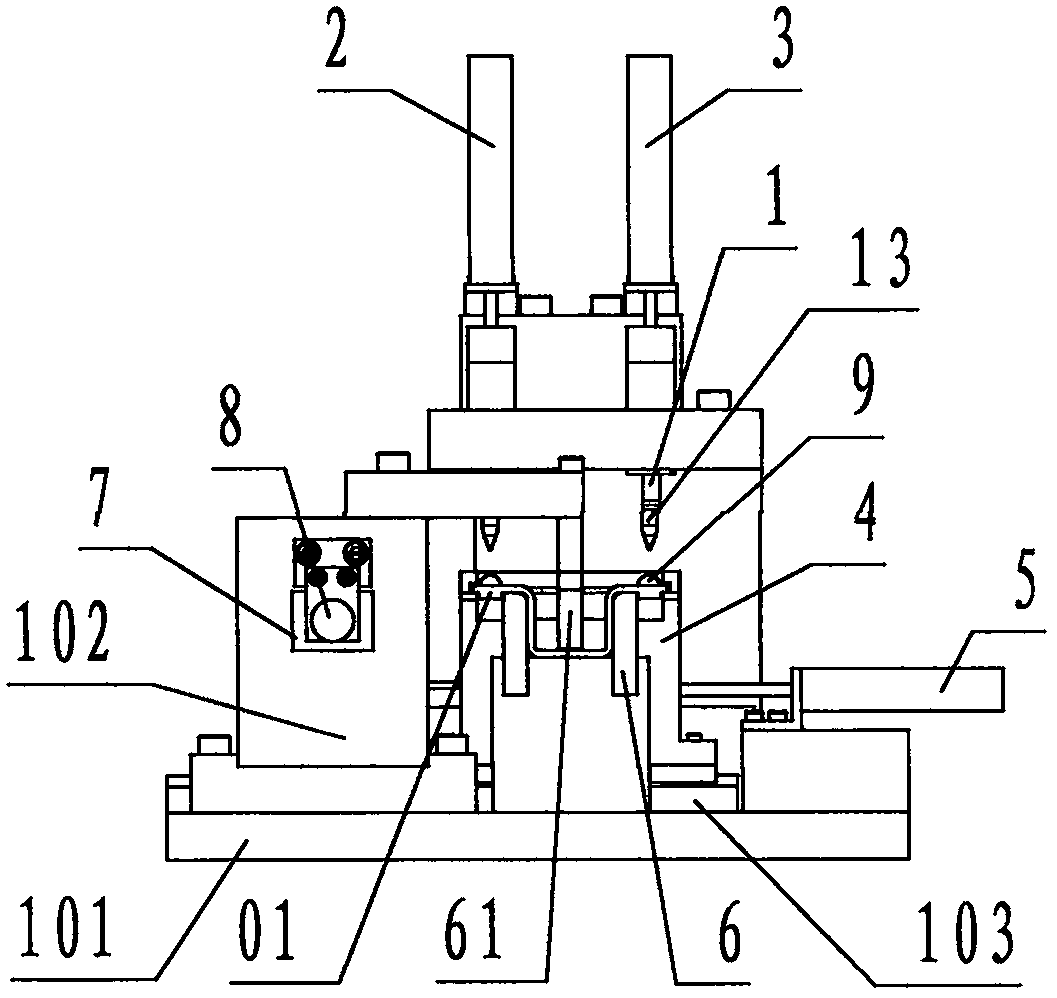

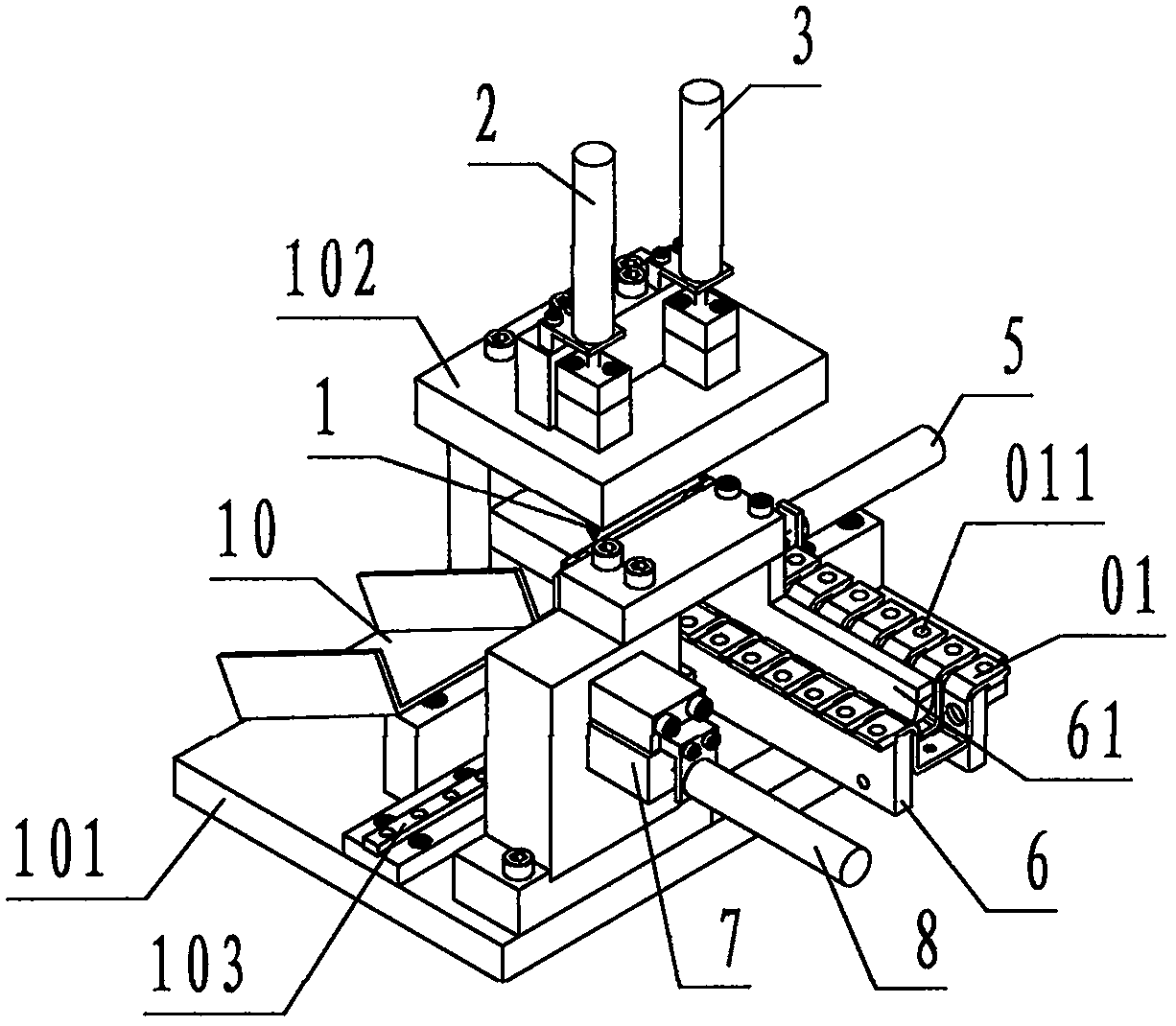

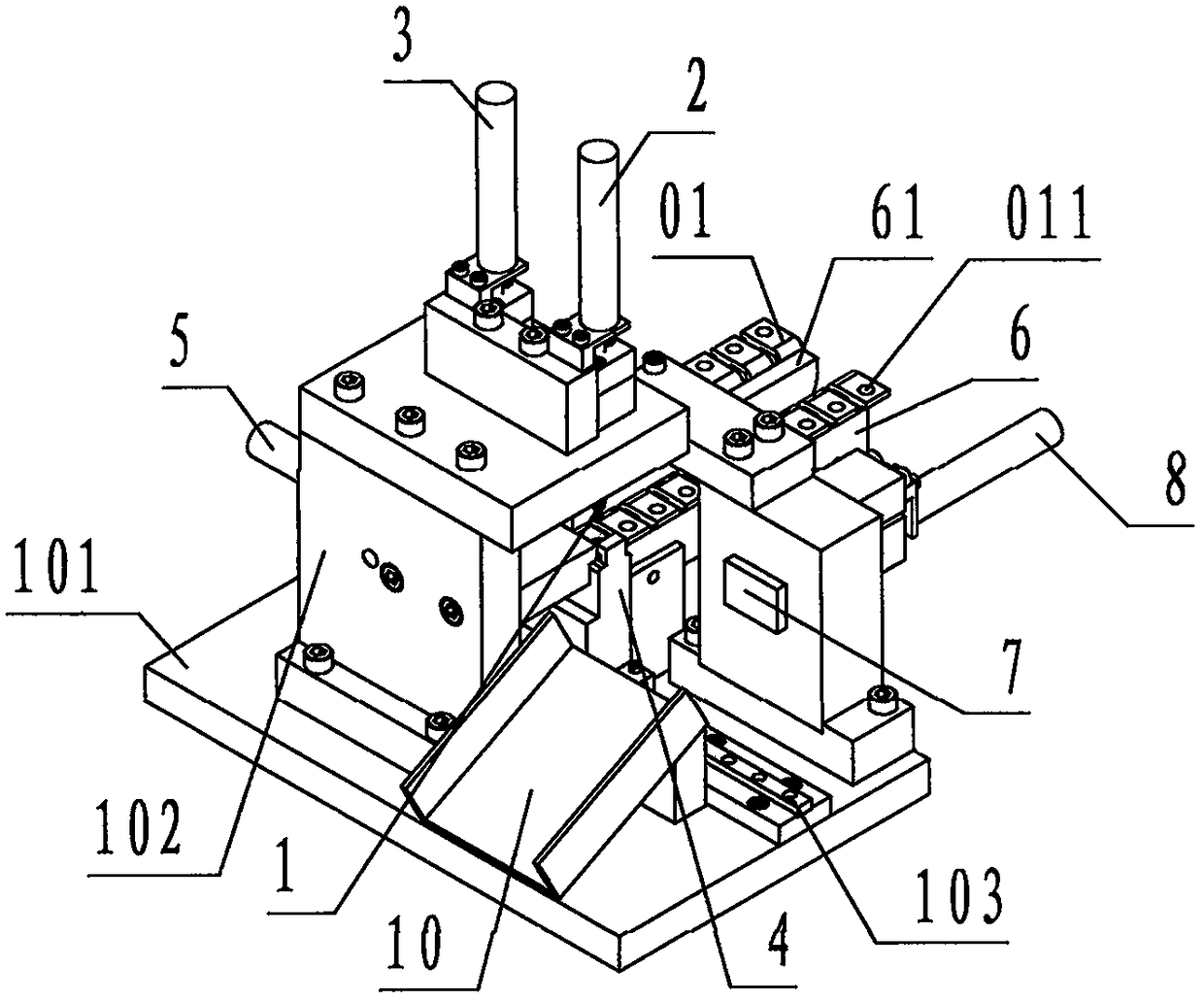

[0037] refer to Figure 1 to Figure 7 , an intelligent automatic detection device for missing thread of a bracket of the present invention, comprising a hole probe 1, an A cylinder 2, a B cylinder 3, a slider 4, a D cylinder 5, a feed rail 6, a push block 7, a C cylinder 8, a probe 9. Blanking chute 10, base 101, wherein: the base 101 is a rectangular plate-shaped steel member, the base 101 is provided with a bracket 102 and a slide rail 103, and the bracket 102 is made of steel The plates are connected, and the bracket 102 is used to connect and carry the measuring pin 1, the A cylinder 2, the B cylinder 3, the D cylinder 5, the feed rail 6, the push block 7, the C cylinder 8, the probe 9 and the blanking slide. The general term for the support structure of the groove 10; the slide rail 103 is a strip-shaped steel member with a convex cross-section, and the slide rail 103 is located in the middle of the base 101 along the left and right directions; the borer 1 is cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com