Exhaust valve plate applied to compressor

A technology of compressor exhaust and exhaust valve plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

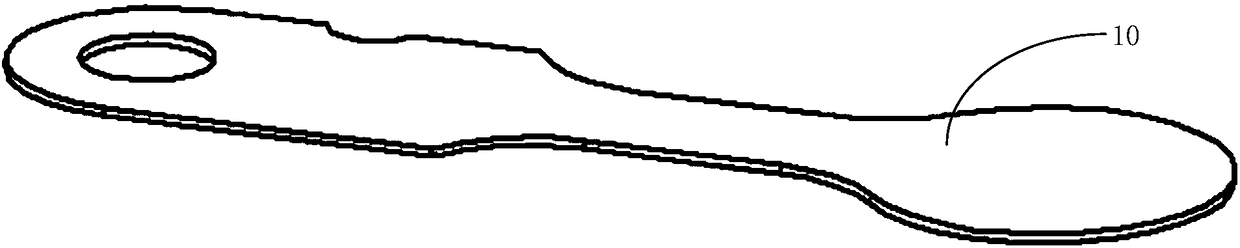

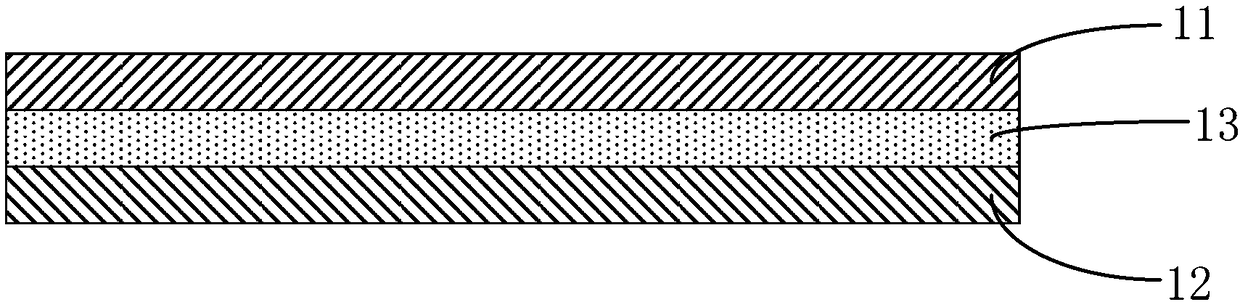

[0017] Such as figure 1 with figure 2 As shown, the compressor discharge valve plate 10 of Embodiment 1 of the present invention has a three-layer composite structure in its main body, and the three-layer composite structure includes a first metal valve layer 11, a damping layer 13 and a second metal valve layer 12 , wherein the damping layer 13 is sandwiched between the first metal valve layer 11 and the second metal valve layer 12 .

[0018] In a specific embodiment of the present invention, the two surfaces of the damping layer 13 are closely combined with the first metal valve layer 11 and the second metal valve layer 12 to form a whole; .

[0019] In a specific embodiment of the present invention, the thickness of the first metal valve layer 11 is 0.1 mm to 1 mm, and its Rockwell hardness is HRC 20 to 60; the thickness of the second metal valve layer 12 is 0.1 mm to 1 mm, Its Rockwell hardness is HRC 20-60. In a specific embodiment of the present invention, the thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com