A Construction Method of Segmented Curtain Grouting in Fault Working Face with Excessive Dip Angle of Shaft Shaft

A technology of curtain grouting and construction method, which is applied in the direction of wellbore/well components, earthwork drilling, sealing/isolation, etc., and can solve the problems of large amount of pore-making engineering, many grouting holes, and poor grouting effect. Achieving good injectability, improving drilling efficiency and shortening the well construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

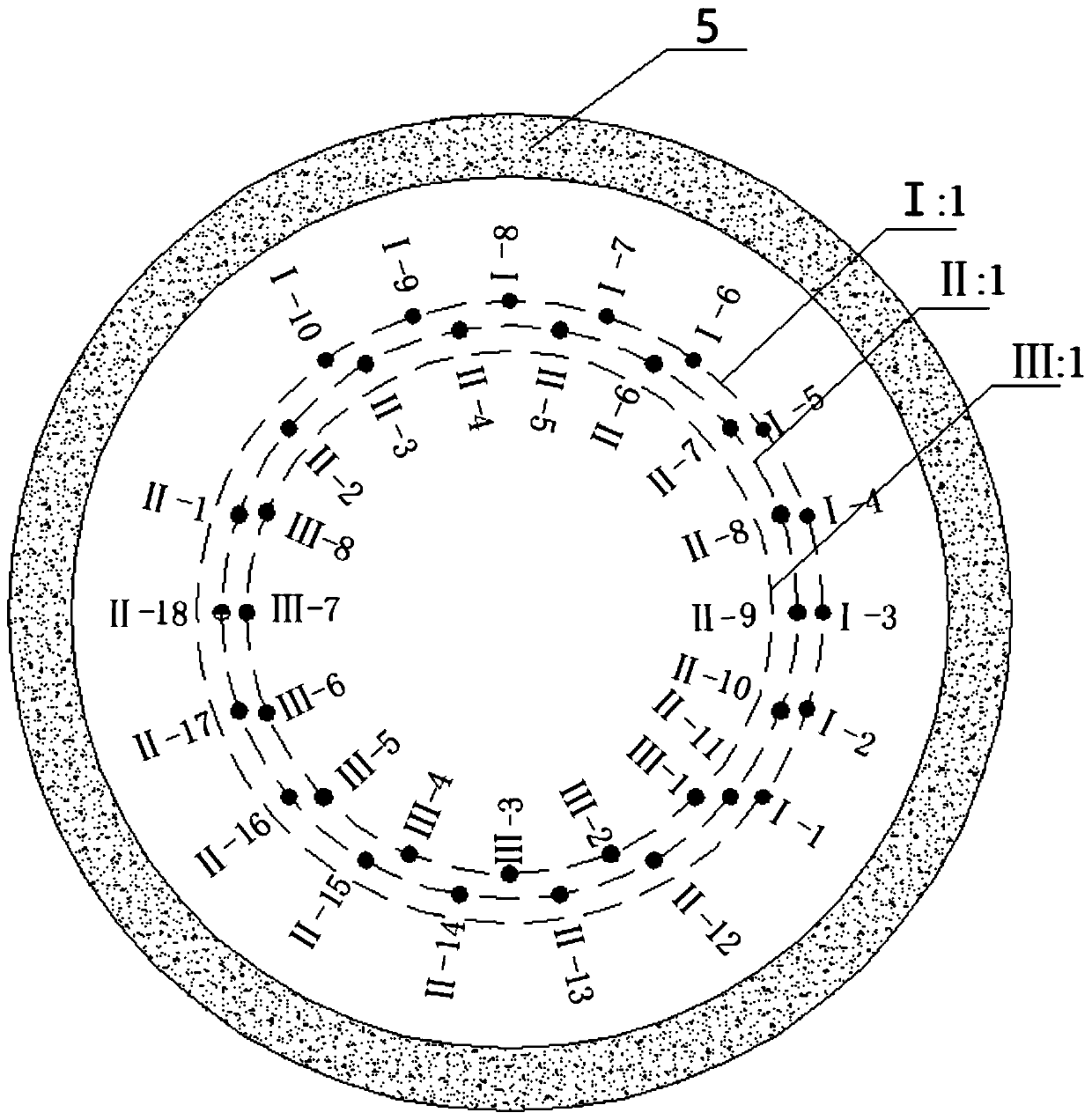

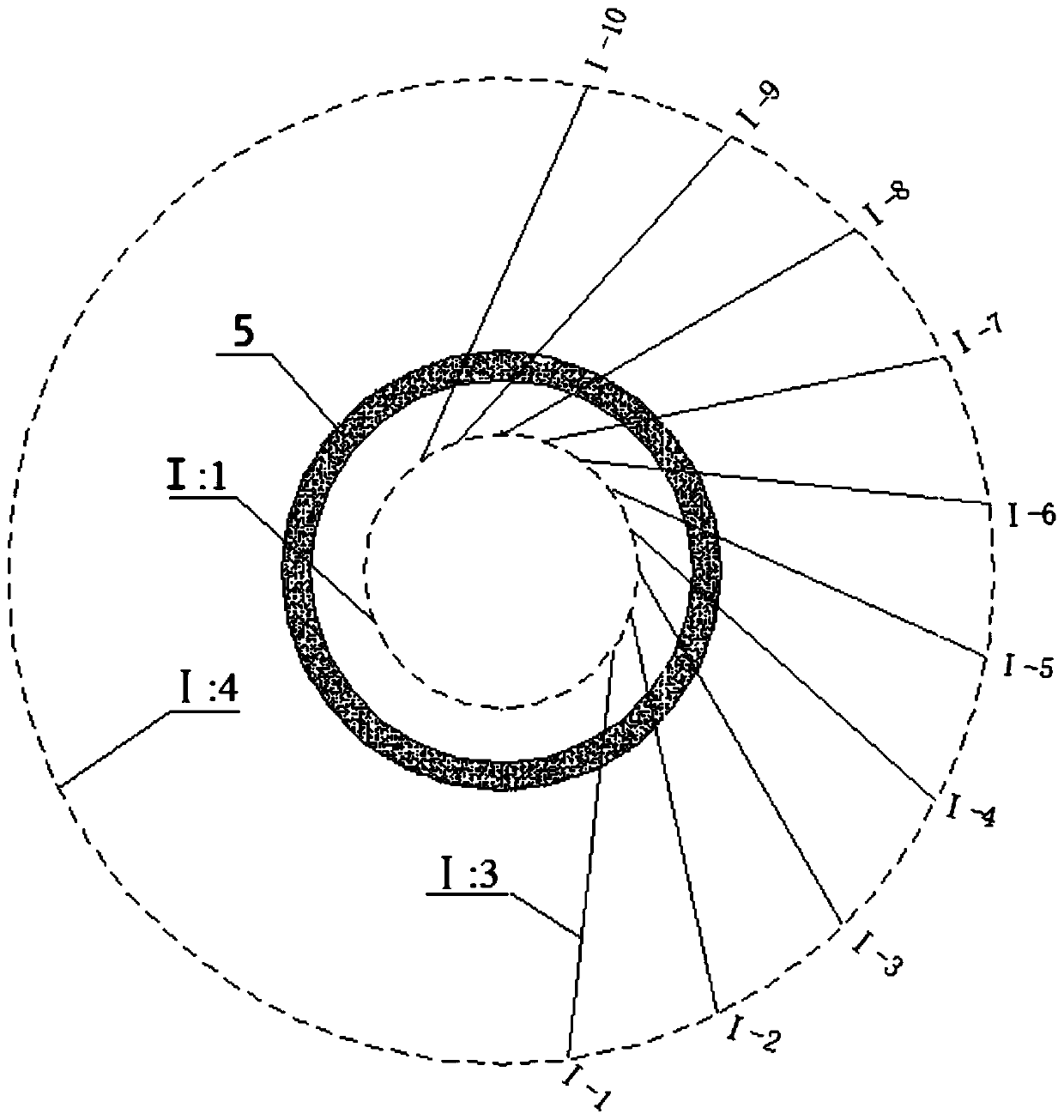

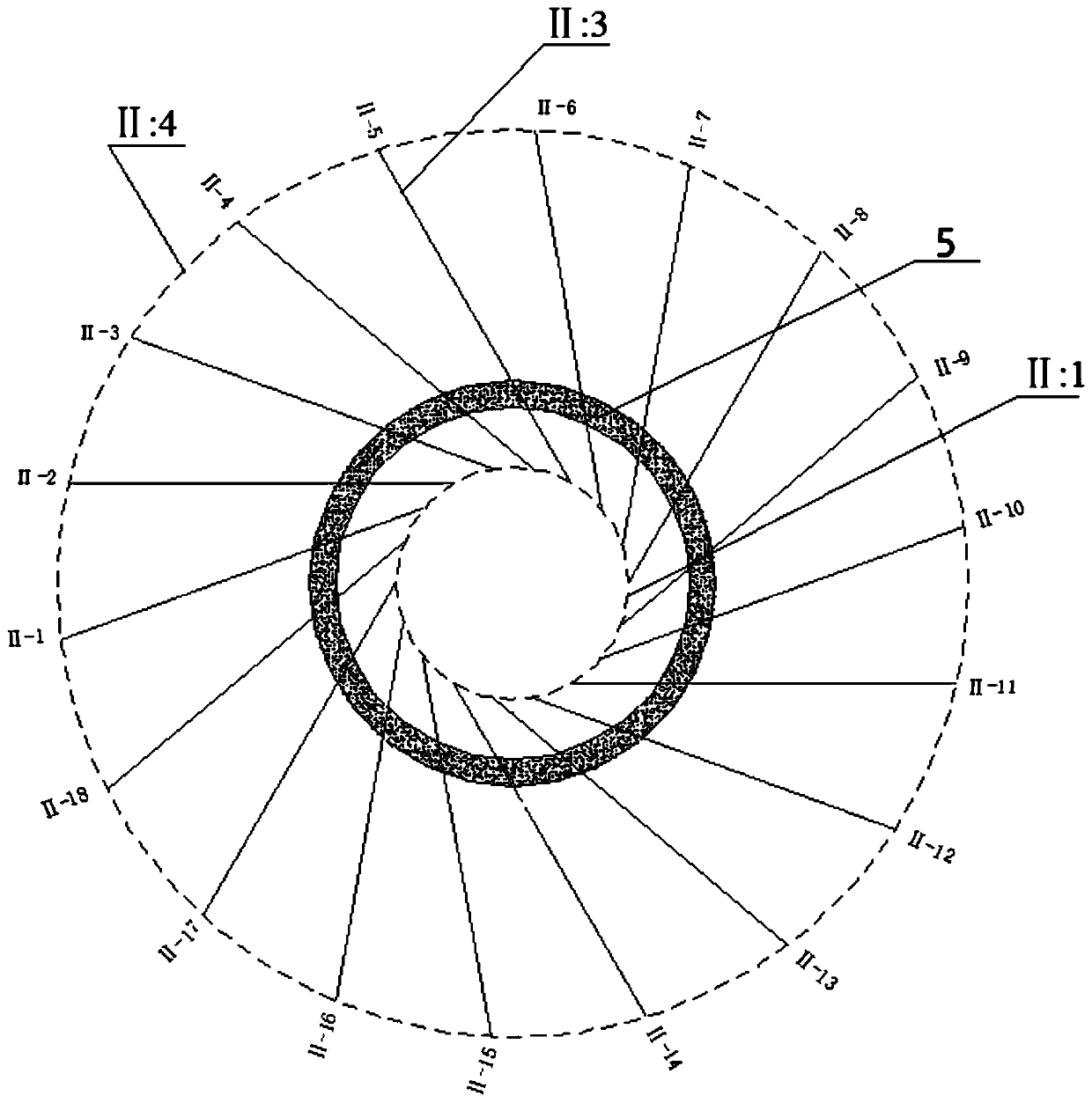

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

[0034] A segmented curtain grouting construction method for a working face on a fault with an excessively large dip angle in a vertical shaft shaft. The excavation face of the vertical shaft shaft is constructed in segments in terms of depth. The distance between the bottom surfaces of each segment is 20-40 m. On the bottom surface of each section, after the construction of the previous shallow section is completed, the next deep section will be constructed; during the construction of each section, the shaft shaft will be excavated first, and when the bottom surface of the current section is reached, the shaft will be excavated. The wall and the grouting cushion are poured, and then the construction is drilled and grouted to complete the construction of the current section. For each segment, it is necessary to pour a concrete grout-proof cushion on the excavation face ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com