Bottle body vein manufacturing method and structure thereof

A manufacturing method and texture technology, applied in the direction of bottle, lining/inner coating, coating, etc., can solve the problems that it is difficult to render the bottle transparent or transparent, the technical difficulty of the bottle surface painting, and the lack of perspective effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

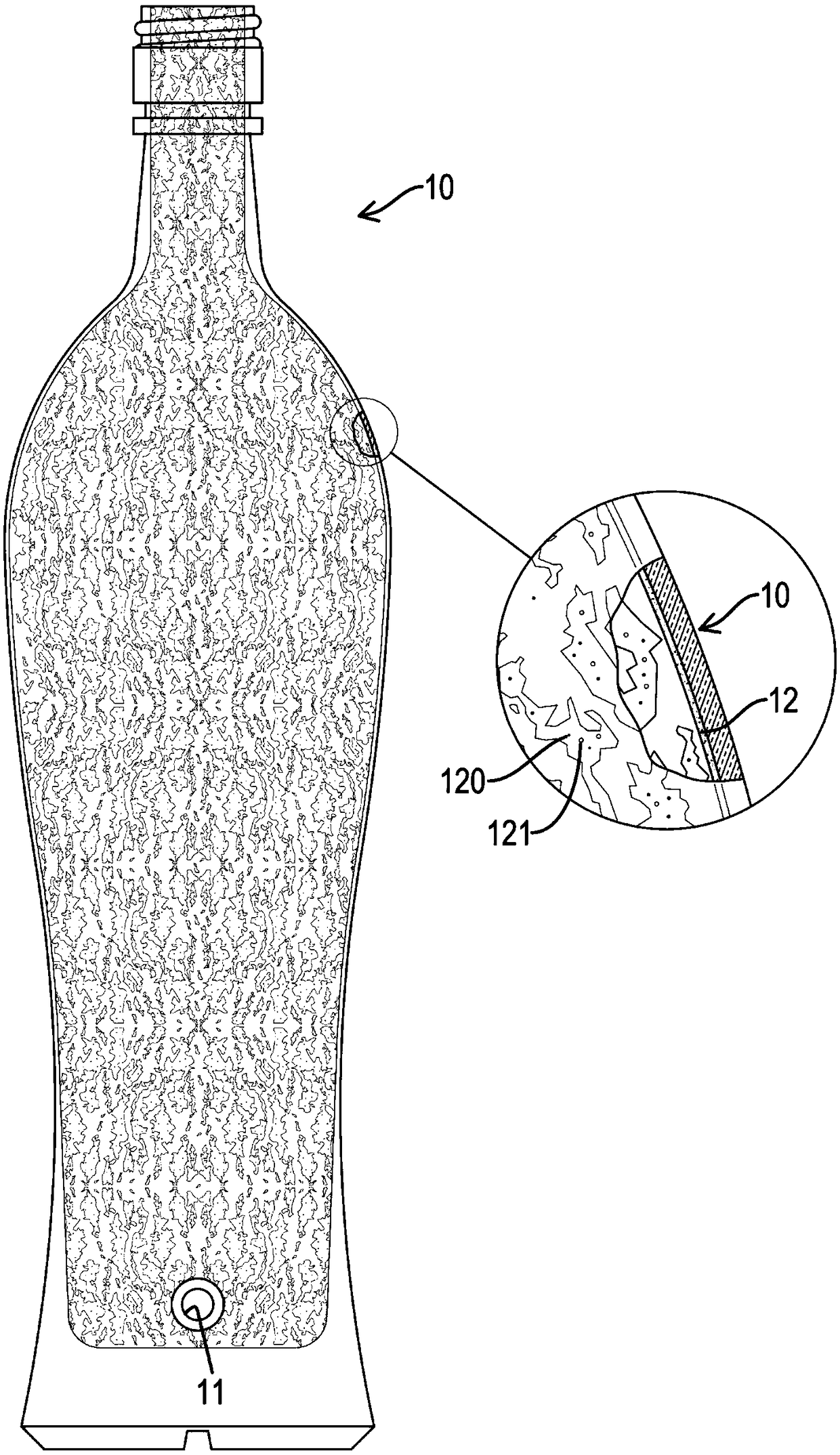

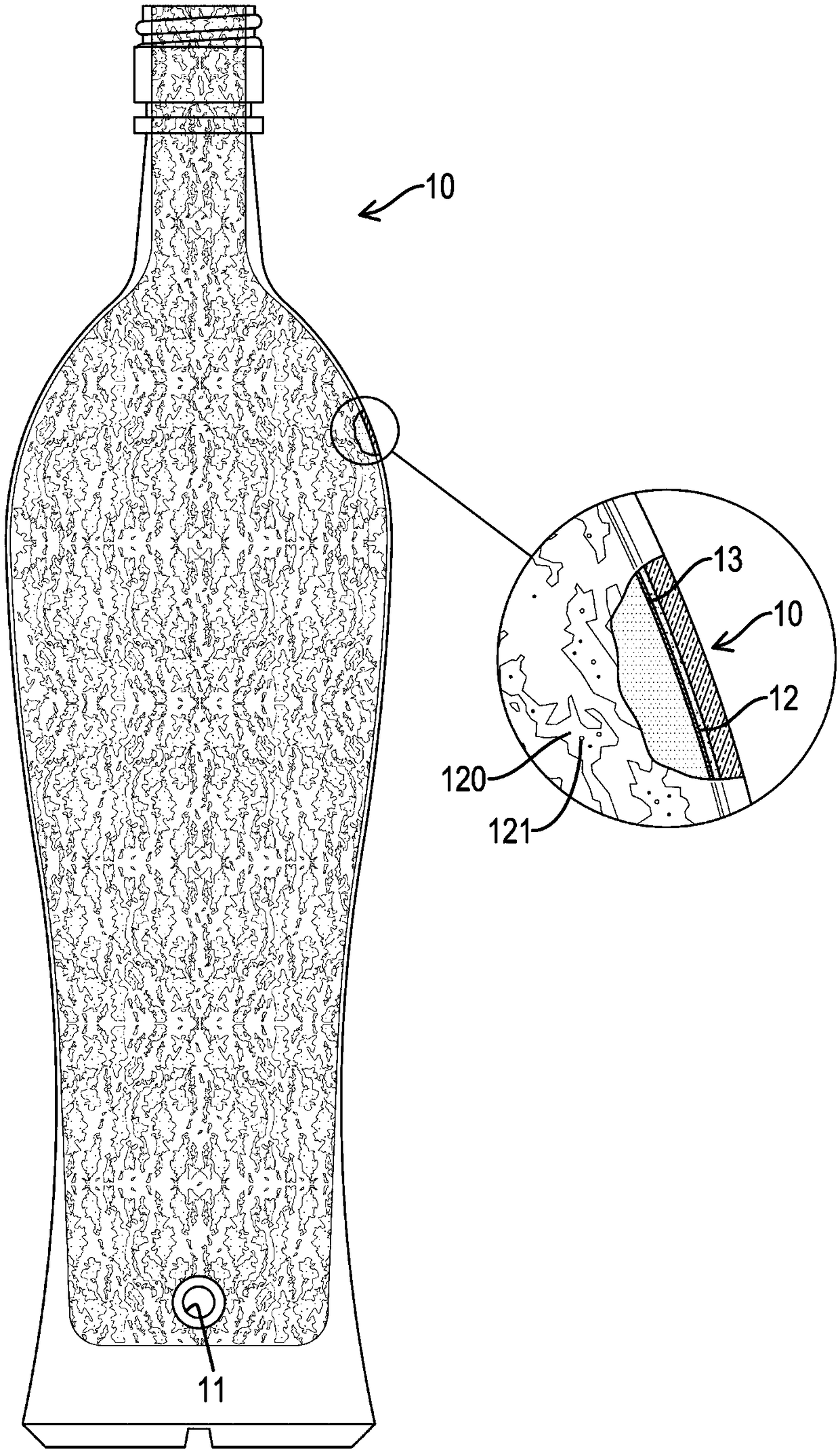

[0037] In order to understand the technical characteristics and practical effects of the present invention in detail, and to realize them according to the contents of the specification, the preferred embodiment shown in the drawings will be described in detail as follows:

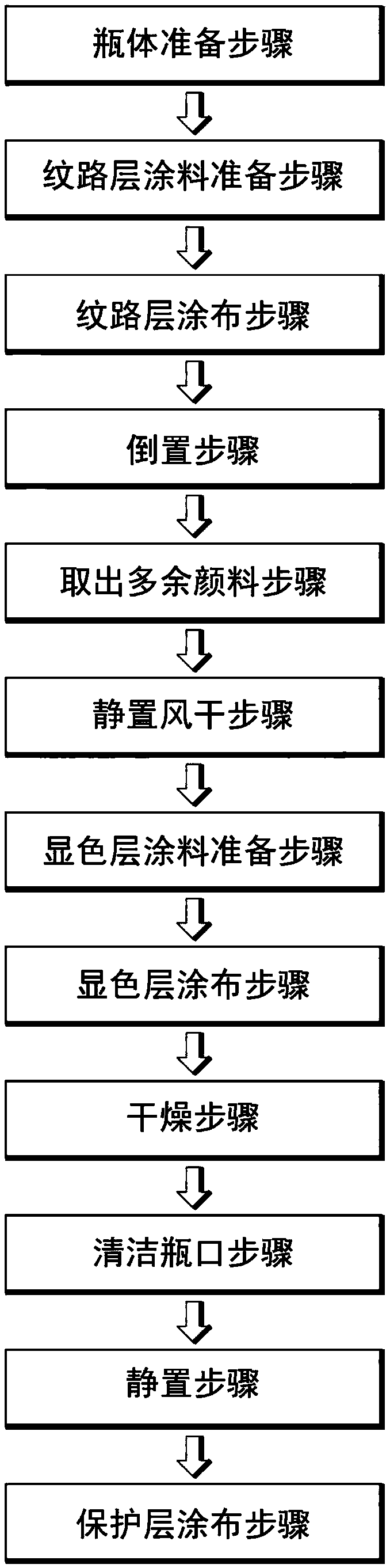

[0038] For the manufacturing method of the bottle body texture of the present invention, please refer to Figure 1 to Figure 4 , including the following steps:

[0039] Bottle body preparation step: prepare a transparent or translucent bottle body 10, and open an outflow hole 11 on the peripheral surface near the bottom of the bottle body 10, preferably, the bottle body 10 can be glass or plastic, etc. light material;

[0040] Texture layer paint preparation step: the model paint is mixed with at least one pigment, preferably, the model paint contains oily synthetic resin organic solvent and synthetic resin paint, the ratio of the two is 7:10, the model paint and The ratio of the pigment is 10:0.6, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com