High-precision motor output shaft starting gear press fitting device

A press-fitting device, high-precision technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the axial end face error of the motor end cover, the difficulty of ensuring the position of the starting gear, and the difficulty of coaxiality between the starting gear and the motor shaft. Guarantee and other issues, to achieve the effect of accurate position, good coaxiality, and high-precision press-fitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below according to the accompanying drawings and specific embodiments.

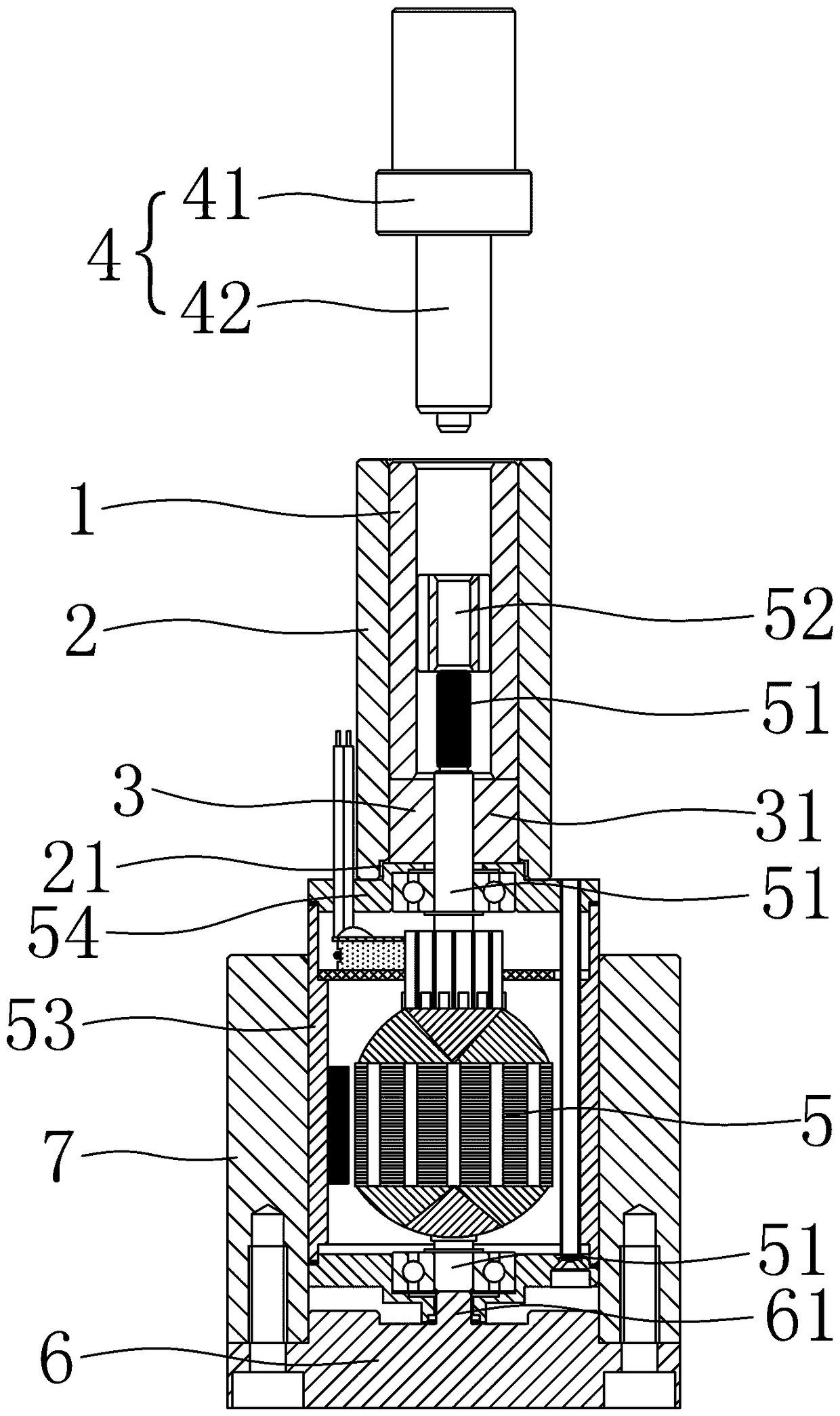

[0014] Depend on figure 1 As shown, a high-precision motor shaft starting gear pressing device of the present invention includes a first sleeve 1, a second sleeve 2, a limit block 3 and a pressure head 4, the first sleeve 1 and the second sleeve The barrel 2 has a through groove that penetrates up and down, the limit block 3 and the first sleeve 1 are both used to be sleeved outside the motor shaft 51, and the first sleeve 1 is supported on the limit block 3, and the second sleeve 2 Used to be sleeved outside the limit block 3 and the first sleeve 1 so that the second sleeve 2, the limit block 3 and the first sleeve 1 are coaxially arranged, when the starting gear 52 is placed in the first sleeve 1 , the circumferential outer wall of the starting gear 52 is in clearance fit with the circumferential inner wall of the first sleeve 1, the limit block 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com