Crop straw vaporization furnace

A technology for crop straw and gasification furnace, which is used in coke ovens, biofuels, special forms of dry distillation, etc., can solve the problems of high device cost, complicated structures of the first furnace chamber and the second furnace chamber, etc., to improve the service life and avoid thermal deformation. Too large, reducing the effect of disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

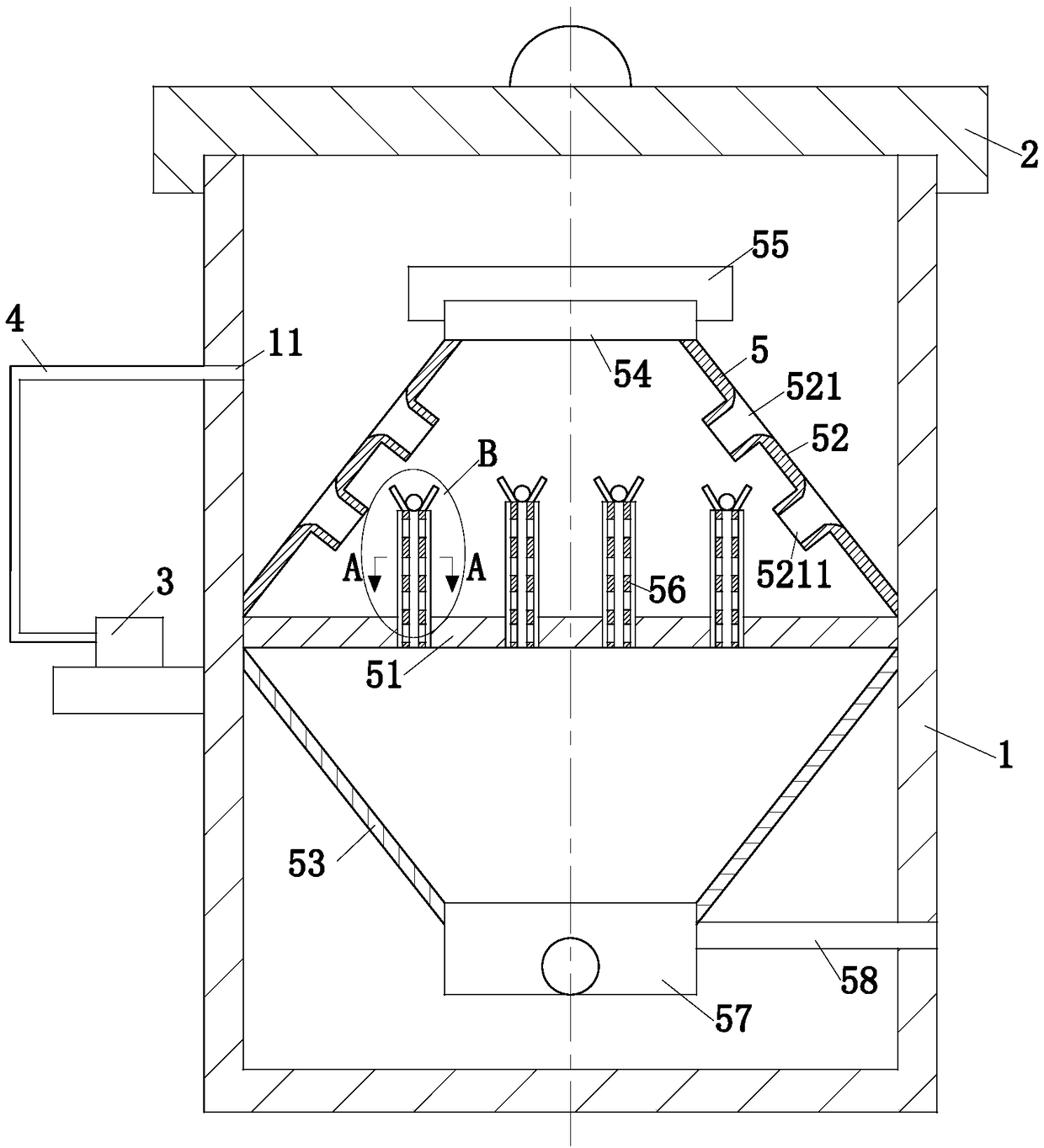

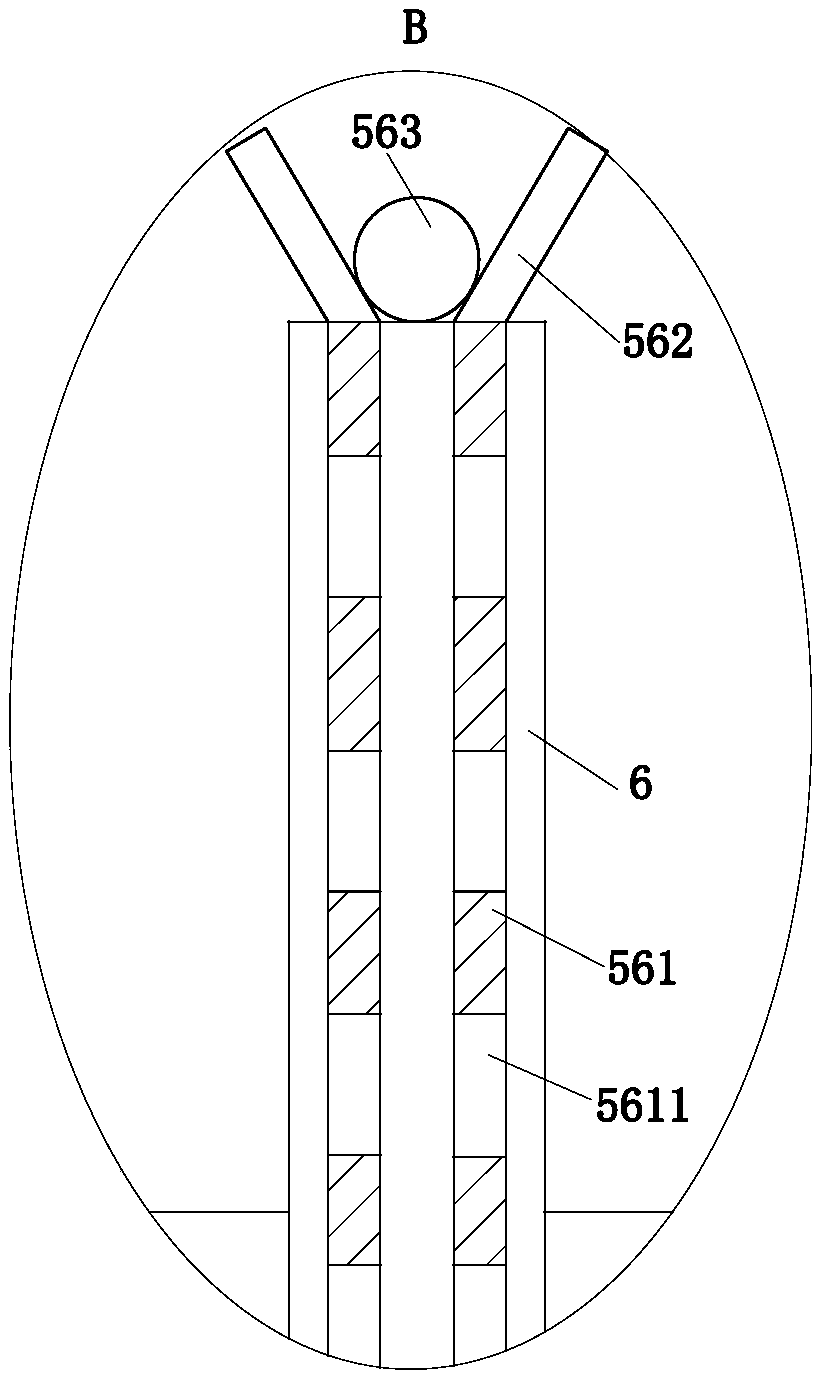

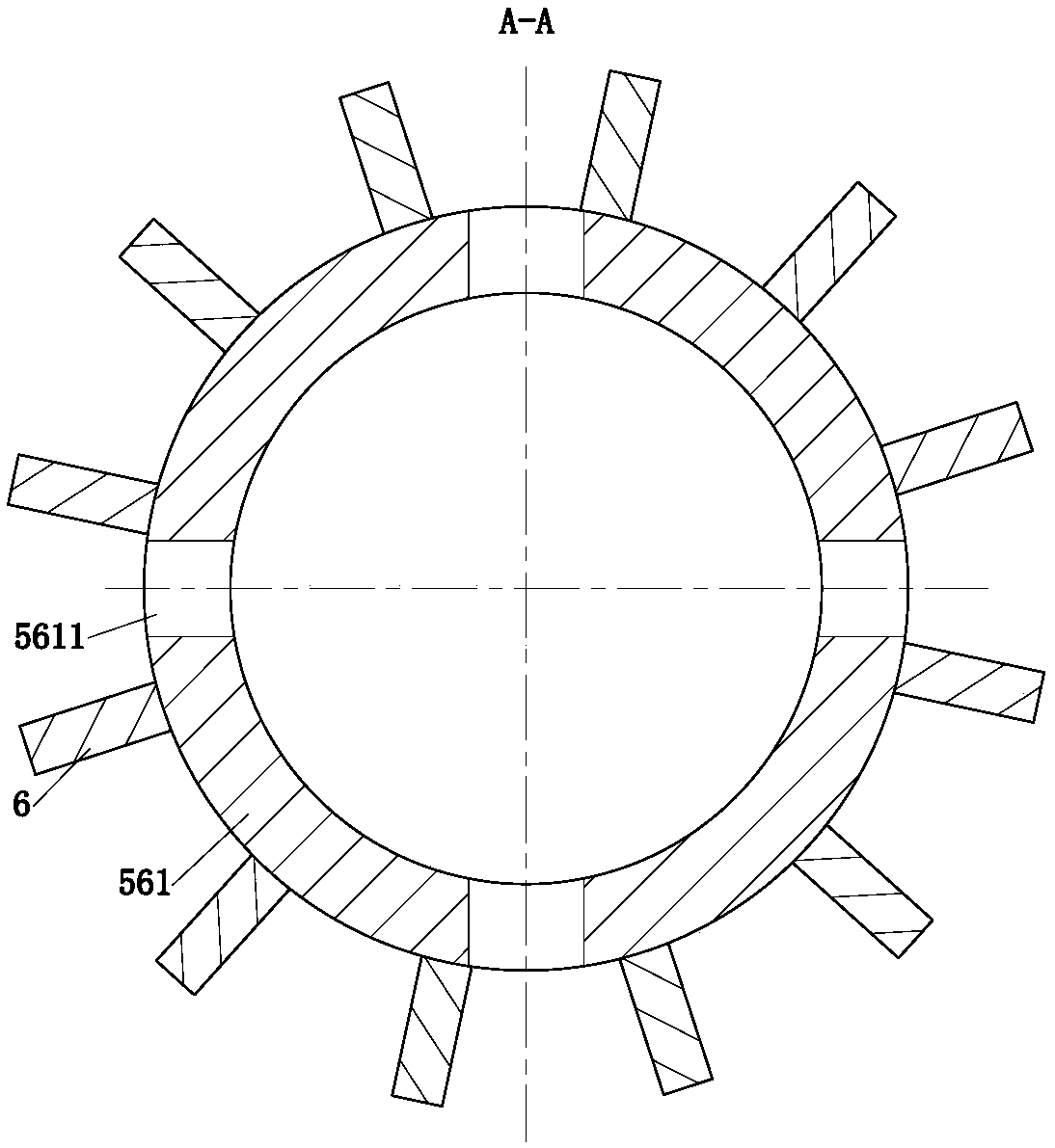

[0025] use Figure 1 to Figure 4 The structure of a charging device for a new energy vehicle according to an embodiment of the present invention will be described as follows.

[0026] Such as figure 1 As shown, a crop straw gasification furnace according to the present invention includes a furnace body 1, a first sealing cover 2, a handle, a fan 3, a placement plate and a ventilation pipe 4, the furnace body 1 is cylindrical, and the furnace body The central axis of 1 is placed vertically, and the side wall of the furnace body 1 is provided with an air inlet 11; the first sealing cover 2 is a disc-shaped structure with a flange 5211 at the bottom, and the first sealing cover 2 is placed horizontally on the furnace body 1 The top of the handle; the handle is connected to the top center of the first sealing cover 2, and the handle is convenient for lifting the first sealing cover 2; The pipe 4 is connected to the air inlet 11 on the side wall of the furnace body 1. The gasificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com