Automobile clutch shell

A technology for clutch housings and automobiles, applied in clutches, friction clutches, mechanically driven clutches, etc., can solve problems such as the inability to apply hybrid electric vehicles, achieve extended service life and work performance, good strength and corrosion resistance, and reduce use costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

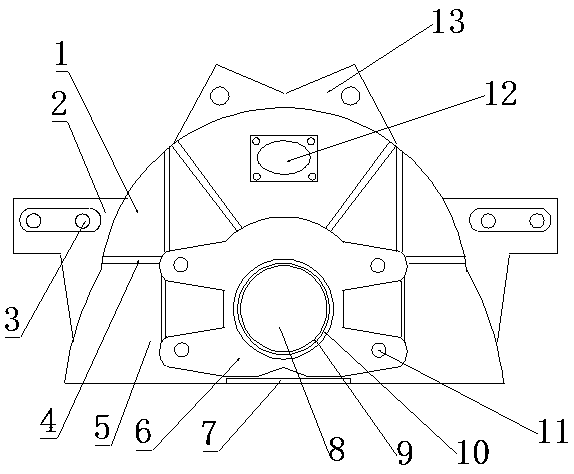

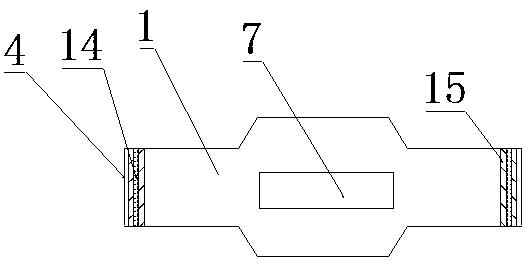

[0017] Such as Figure 1-2 As shown, a clutch housing for automobiles, which includes a housing main body 1, above the housing main body 1 is provided with lugs 13, and the left and right sides of the housing main body 1 are provided with bosses 2, each of the At least two locating pin positions 3 are provided on each hanging lug 13 and the boss 2, the front of the shell main body 1 is provided with a cavity 5, and the center of the cavity 5 is provided with a bearing seat 8. A plurality of reinforcing ribs 4 are provided between the bearing seat 8 and the cavity 5, and above the bearing seat 8 and the reinforcing ribs 4, there is a mechanical manipulation installation surface 6 matched with the bearing seat 8. The mechanical A mechanical manipulation installation position 11 is provided on the manipulation installation surface 6, a flame retardant heat insulation layer 9 is provided around the bearing housing 8, a resolver positioning pin 10 is provided on the mechanical mani...

Embodiment 2

[0020] Such as Figure 1-2 As shown, a clutch housing for automobiles, which includes a housing main body 1, above the housing main body 1 is provided with lugs 13, and the left and right sides of the housing main body 1 are provided with bosses 2, each of the At least two locating pin positions 3 are provided on each hanging lug 13 and the boss 2, the front of the shell main body 1 is provided with a cavity 5, and the center of the cavity 5 is provided with a bearing seat 8. A plurality of reinforcing ribs 4 are provided between the bearing seat 8 and the cavity 5, and above the bearing seat 8 and the reinforcing ribs 4, there is a mechanical manipulation installation surface 6 matched with the bearing seat 8. The mechanical A mechanical manipulation installation position 11 is provided on the manipulation installation surface 6, a flame retardant heat insulation layer 9 is provided around the bearing housing 8, a resolver positioning pin 10 is provided on the mechanical mani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com