Method for continuous reduction and ingot casting of germanium dioxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

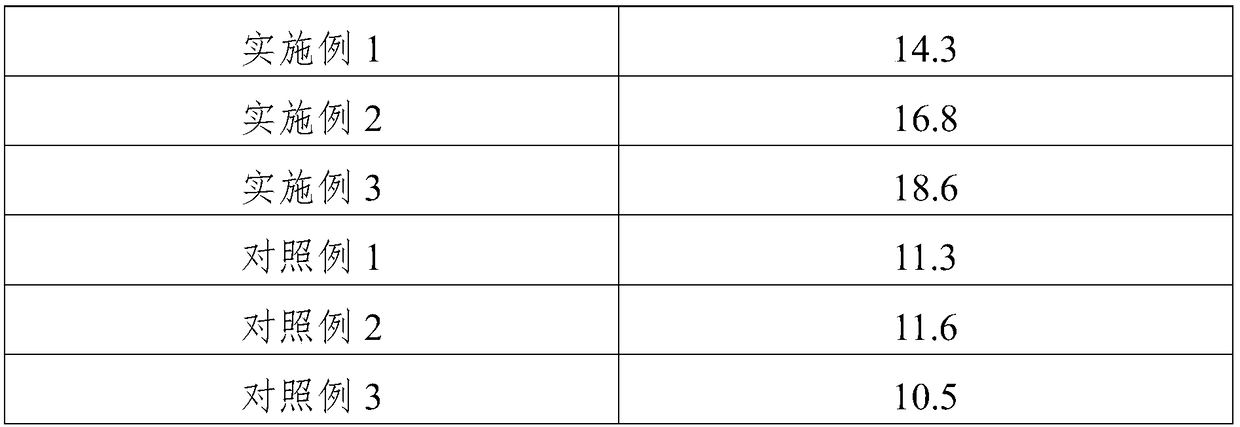

Embodiment 1

[0018] An embodiment of the present invention is a method for continuous reduction of germanium dioxide ingot casting, the method comprising the following steps:

[0019] Put the germanium dioxide into the graphite boat and put it into the furnace, wherein the amount of the germanium dioxide loaded in the boat is 70% of the capacity of the graphite boat. Under the hydrogen atmosphere, the graphite boat loaded with the germanium dioxide passes through seven heating Temperature zones, the temperatures of the seven heating temperature zones are: 200°C, 400°C, 500°C, 600°C, 700°C, 800°C, 1000°C; the graphite boat loaded with germanium dioxide is in the seven temperature zones The residence time in the medium is 30min respectively; subsequently, the germanium ingot is obtained by cooling down.

Embodiment 2

[0021] An embodiment of the present invention is a method for continuous reduction of germanium dioxide ingot casting, the method comprising the following steps:

[0022] Put the germanium dioxide into the graphite boat and put it into the furnace, wherein the amount of the germanium dioxide loaded in the boat is 90% of the capacity of the graphite boat. Under the hydrogen atmosphere, the graphite boat loaded with the germanium dioxide passes through seven heating temperature zone, the temperatures of the 7 heating temperature zones are respectively: 400°C, 500°C, 600°C, 700°C, 900°C, 1000°C, 900°C; the graphite boat loaded with germanium dioxide is in the 7 temperature zones The residence time in the medium is 60min respectively; subsequently, the germanium ingot is obtained by cooling down.

Embodiment 3

[0024] An embodiment of the present invention is a method for continuous reduction of germanium dioxide ingot casting, the method comprising the following steps:

[0025] Put the germanium dioxide into the graphite boat and put it into the furnace, wherein the amount of germanium dioxide loaded in the boat is 80% of the capacity of the graphite boat. Under the hydrogen atmosphere, the graphite boat loaded with germanium dioxide passes through 7 heating Temperature zones, the temperatures of the seven heating temperature zones are: 200°C, 450°C, 600°C, 650°C, 750°C, 900°C, 1000°C; the graphite boat loaded with germanium dioxide is in the seven temperature zones The residence time in the medium is 40min respectively; subsequently, the germanium ingot is obtained by cooling down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com