Coke oven refractory protective removal device and removal method

A protective and refractory technology, applied in the field of coke oven refractory protective dismantling devices, can solve the problems of mixed bricks, disordered serial numbers, low dismantling yield, etc., to ensure thickness and strength, reduce errors, improve The effect of demolition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

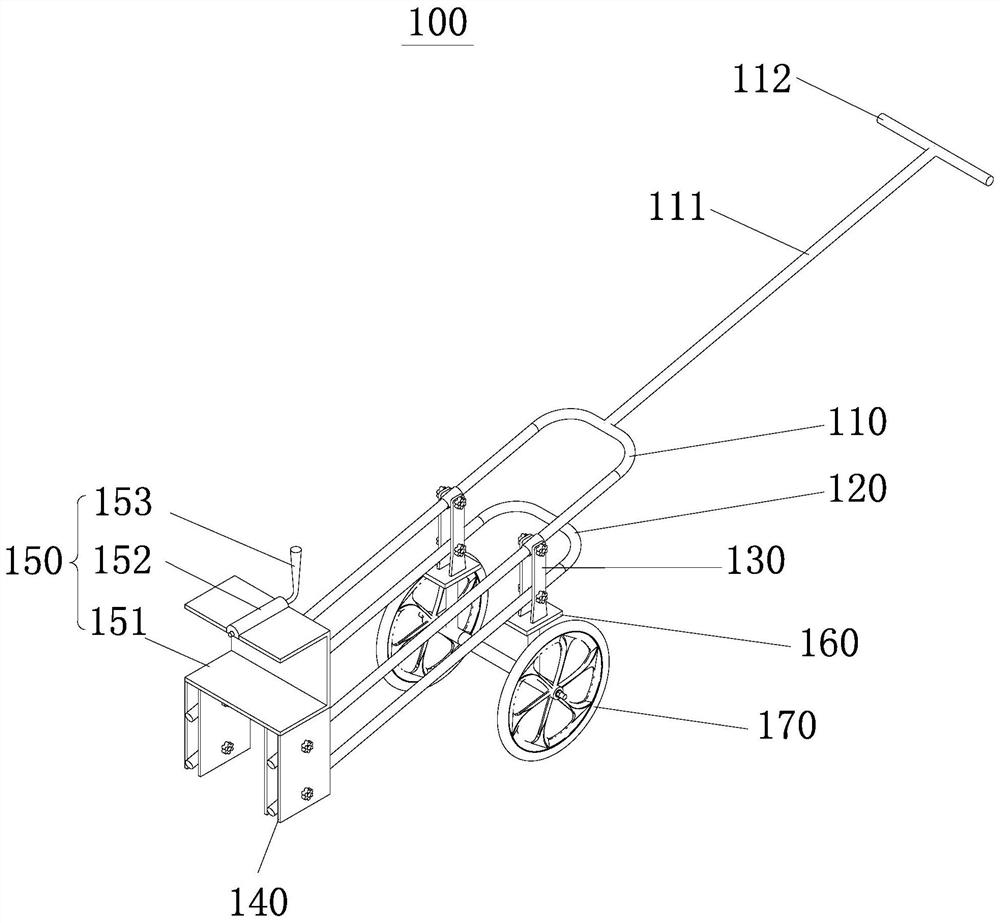

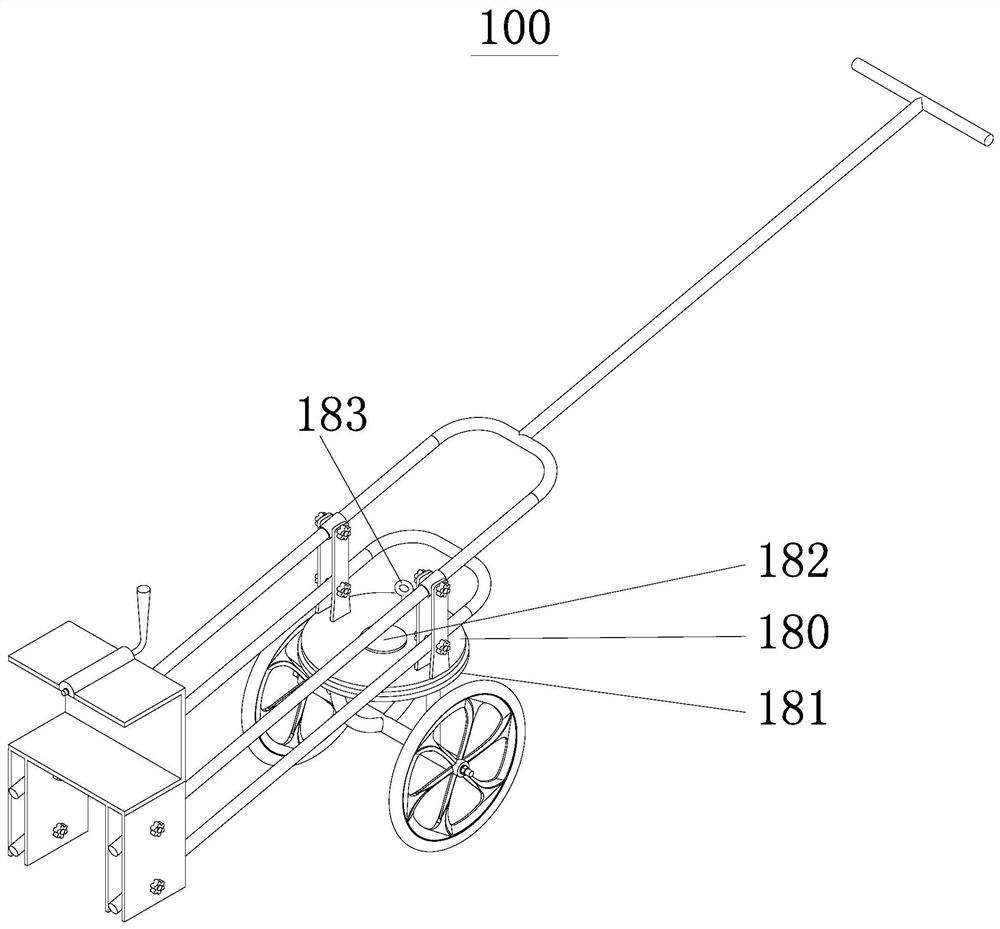

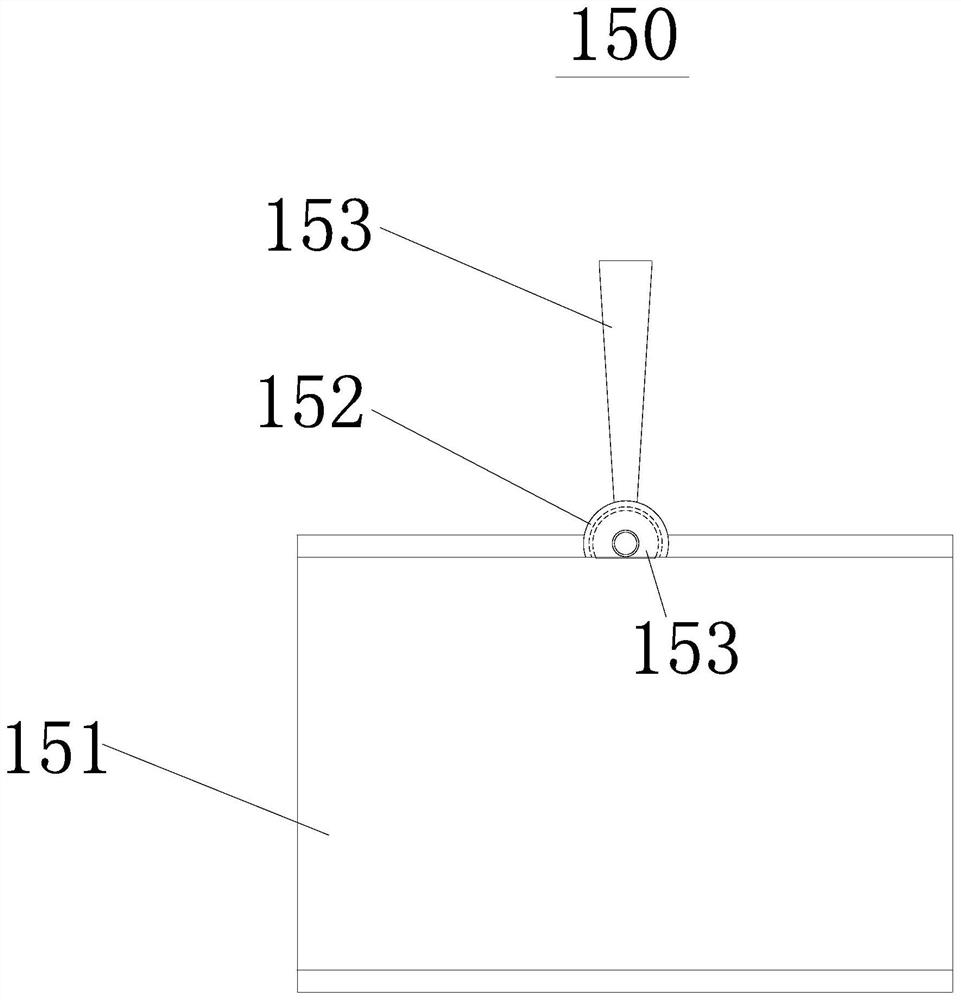

[0053] Such as Figure 1-10 As shown, it is a coke oven refractory protective demolition device according to a preferred embodiment of the present invention, including: a rocker brick dismantling vehicle 100 for dismantling furnace roof overhead bricks, and a brick brick splitter for peeling off smaller bricks. A block separator 200, a gray scar peeling hammer 300 for cleaning large areas of gray scars on bricks, a gray scar cleaner 400 for cleaning the corners, grooves and tongues of bricks, a tool for quickly distinguishing similar bricks The brick scale is 500.

[0054] Such as Figure 1-4 As shown, the rocker arm brick splitting vehicle 100 includes a rocker mechanism, a support base 130, a clamp base 140, a clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com