Vertical double-layer eight-rotor flying robot

A flying robot and eight-rotor technology, applied in the field of drones, can solve problems such as slow response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

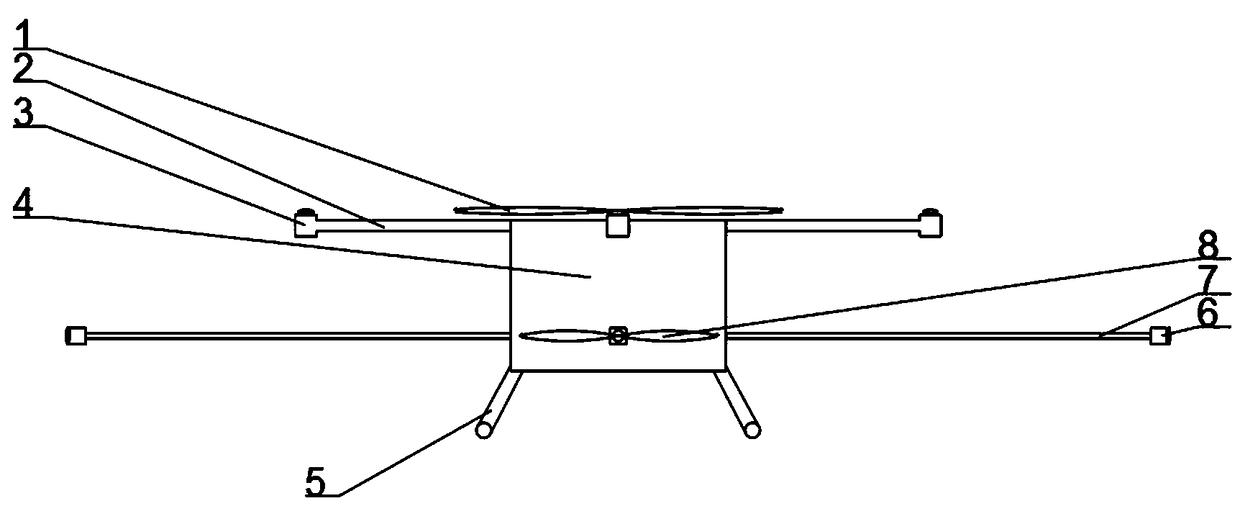

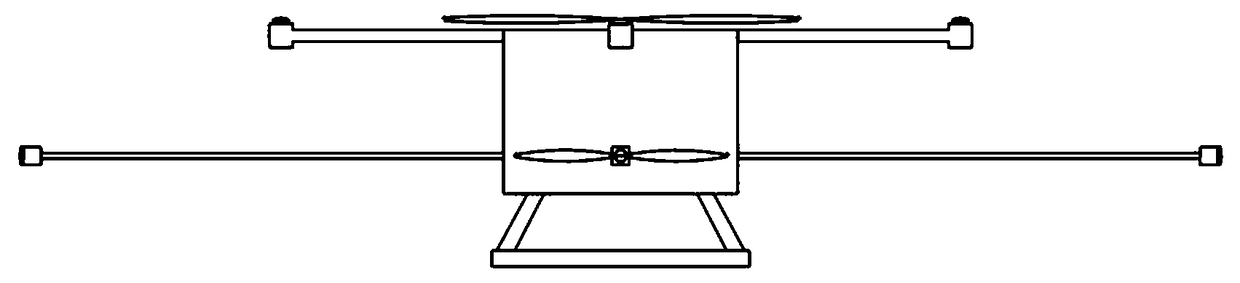

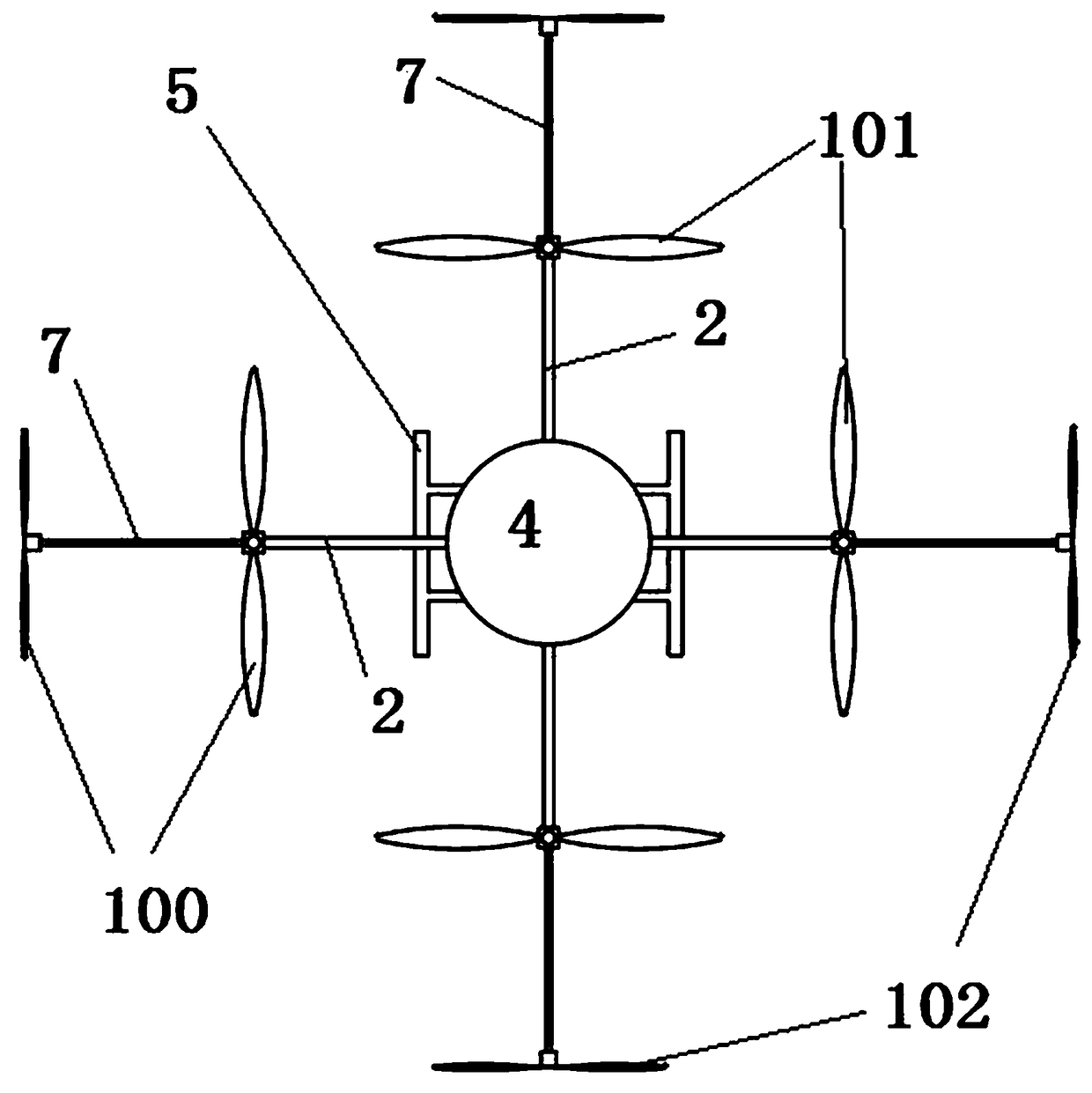

[0066] like Figure 1-7 As shown, a vertical double-layer eight-rotor flying robot, the flying robot includes a control module, a body 4 and a power part; the power part includes a lift part 101 and a thrust part 102; the lift part 101 includes four evenly distributed The lift rotor 1 around the body 4; the four lift rotors 1 are located in the same horizontal plane and at the same distance from the body; the thrust portion 102 includes four thrust rotors 8 evenly distributed around the body 4; the four thrust rotors 8 are located In the same horizontal plane and with the same distance from the body 4; the lift rotor 1 is a horizontal rotor, and the rotating speed of adjacent lift rotors 1 is the same but the direction of rotation is opposite; the thrust rotor 8 is a vertical rotor, and the adjacent thrust rotors 8 The speed is the same but the direction of rotation is opposite.

[0067] The plane where the lift rotor is located is above the plane where the thrust rotor is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com