Intelligent gold stamping method of intelligent gold stamping machine

An intelligent hot stamping machine and intelligent hot stamping technology are applied in the direction of printing machines, rotary printing machines, general parts of printing machinery, etc., which can solve problems such as missed ironing and scrapping, scrapping, etc., to avoid wrong ironing and missed ironing, improve safety, and bronzing Process accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

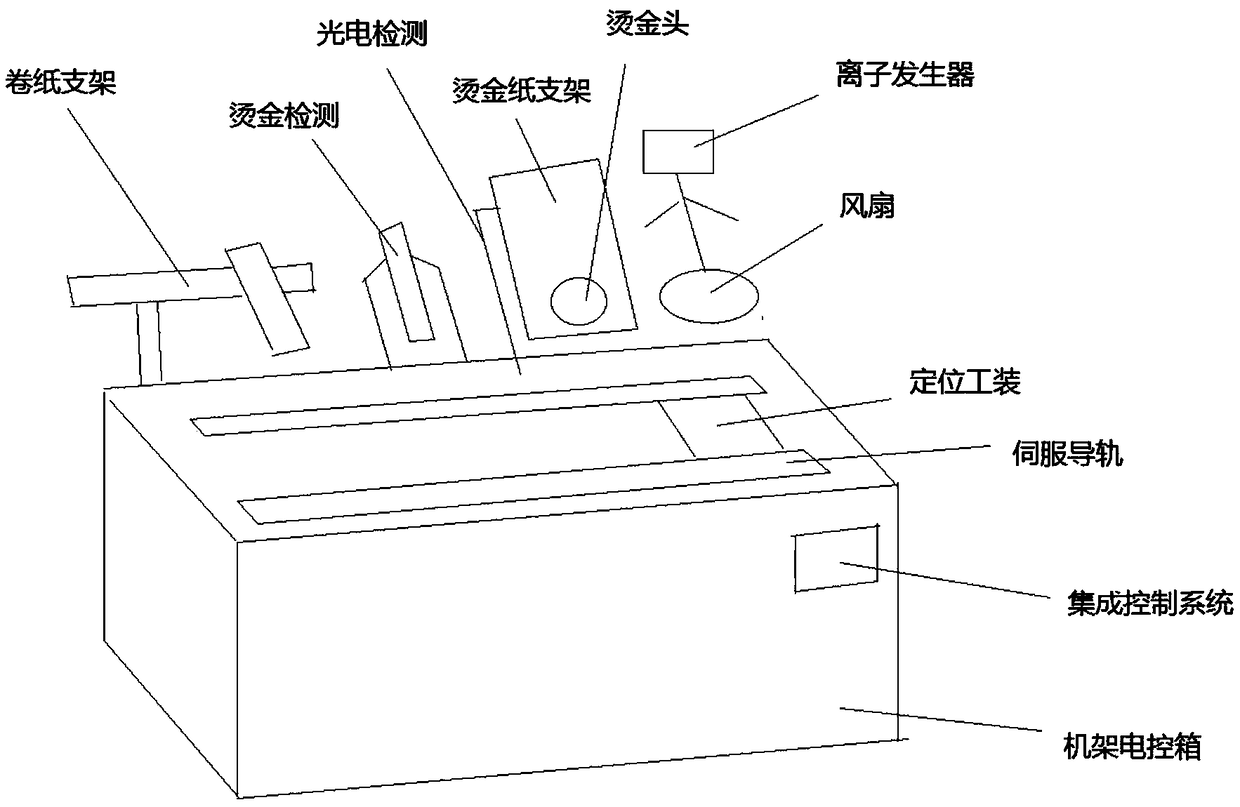

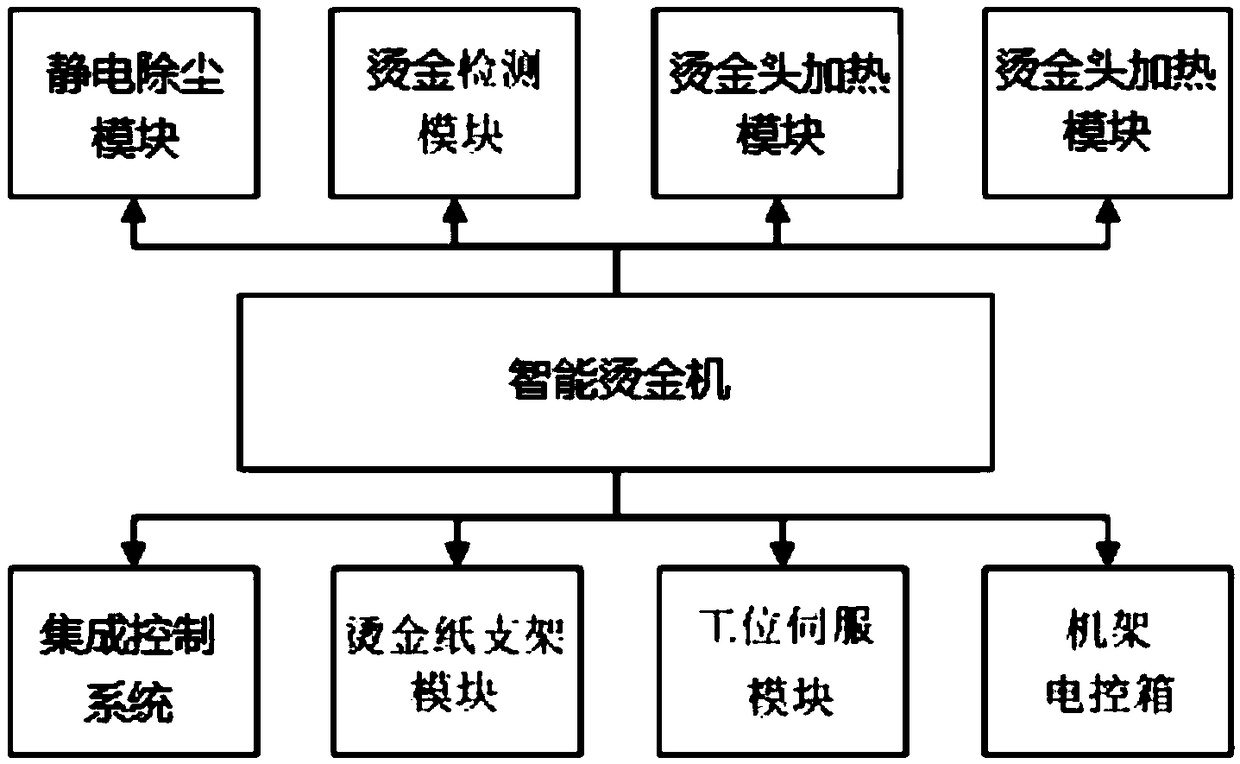

[0044] An intelligent bronzing machine, such as figure 1 shown, including:

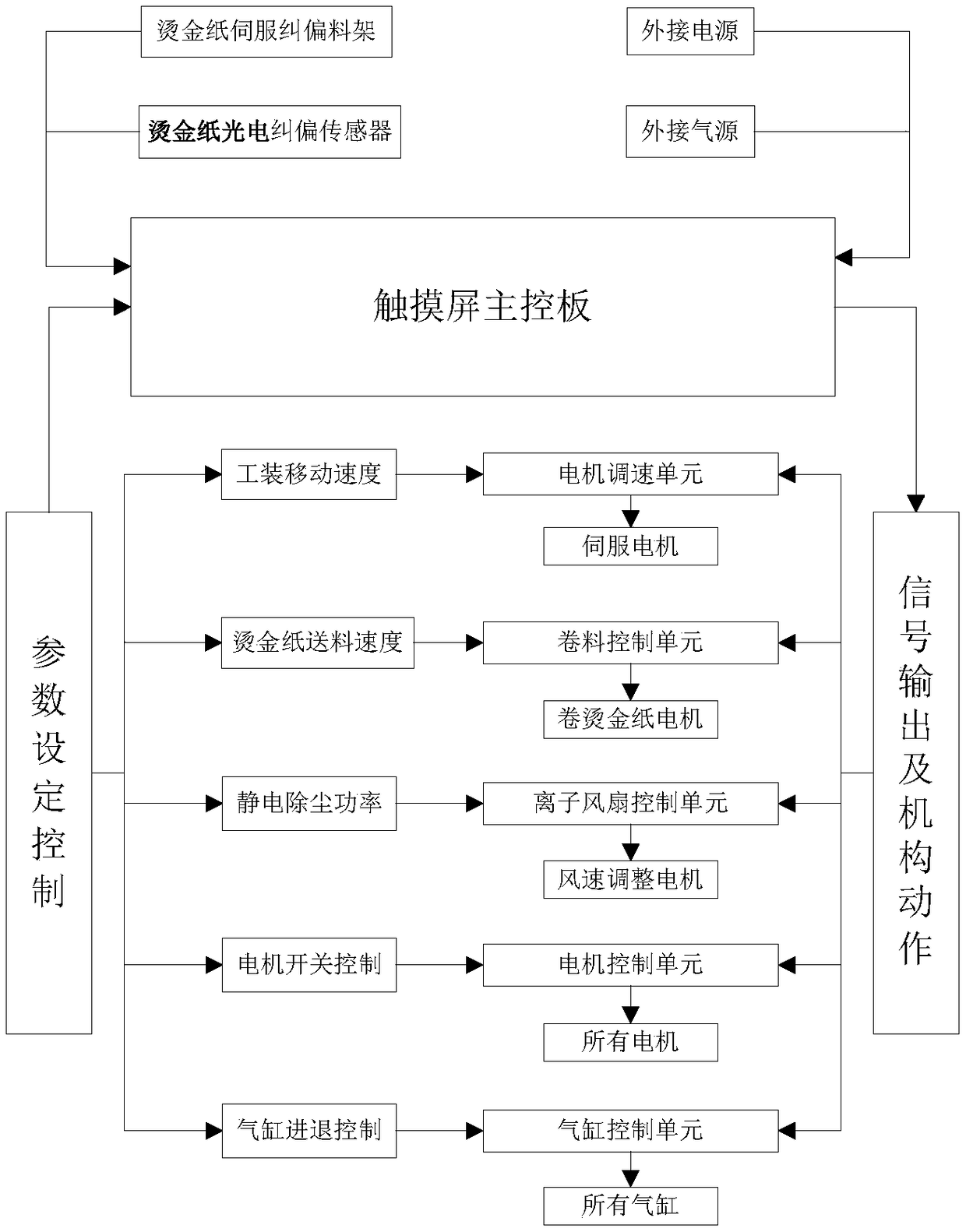

[0045] The frame and the electric control box are used to fix and install each component module of the hot stamping machine, supply power to each component module of the hot stamping machine, and centralize the signal lines of the hot stamping machine; including: power supply and distribution modules, used to connect to external power sources, respectively Supply power to each component module of the hot stamping machine, adjust the voltage and current according to the use needs of each component module, and stabilize the power; the gas supply module is used to connect the external gas source, store and adjust the air pressure, and supply gas to the modules that need to use high-pressure gas The motor control module is used to control the rotation of the motor t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com