Energy-saving fertilizer granulator

A granulator and fertilizer technology, which is applied in the direction of dryers, raw material extrusion granulation, lighting and heating equipment, etc., can solve the problems of low production efficiency, limitations, failure to realize effective energy utilization, etc., and increase the service life , speed up the fall, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

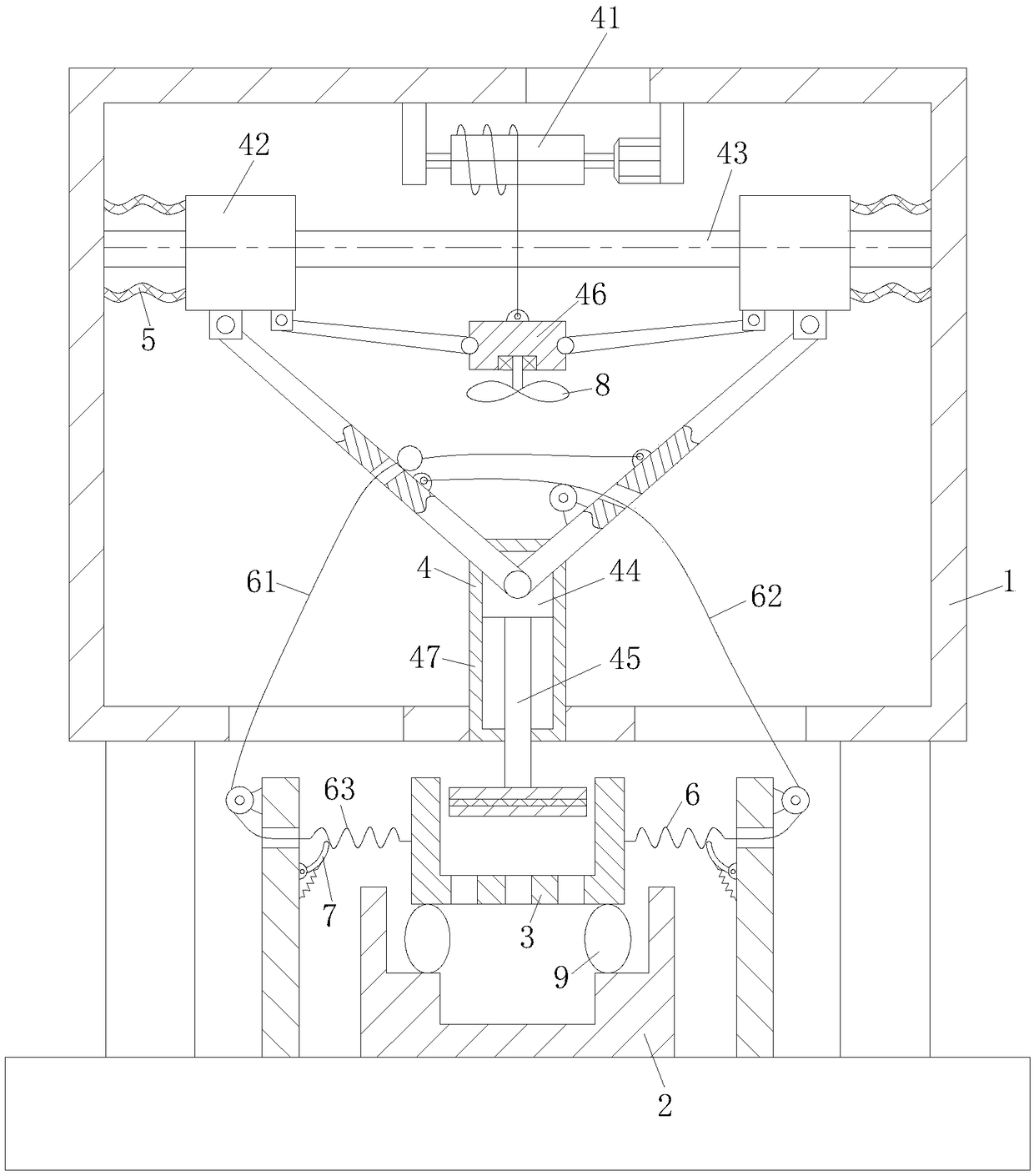

[0021] Such as figure 1 As shown, a kind of energy-saving chemical fertilizer granulator of the present invention comprises working box 1, base, controller and pillar, and described working box 1 is positioned at the top of the base, is connected by two pillars between working box 1 and the base; The controller controls the automatic operation of the granulator; the base is fixedly connected with a material setting platform 2; the material setting platform 2 is provided with an extruding seat 3; the bottom of the extruding seat 3 is provided with evenly distributed through grooves The working box 1 is provided with an extruding module 4; the extruding module 4 is used to extrude the material in the extruding seat 3 into the material setting table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com