A fracture splint with thermal insulation function

A splint and functional technology, applied in the field of medical devices, can solve problems such as troublesome disassembly and unfavorable rehabilitation of patients, achieve good heat dissipation space, avoid low-temperature burns, and promote tissue recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

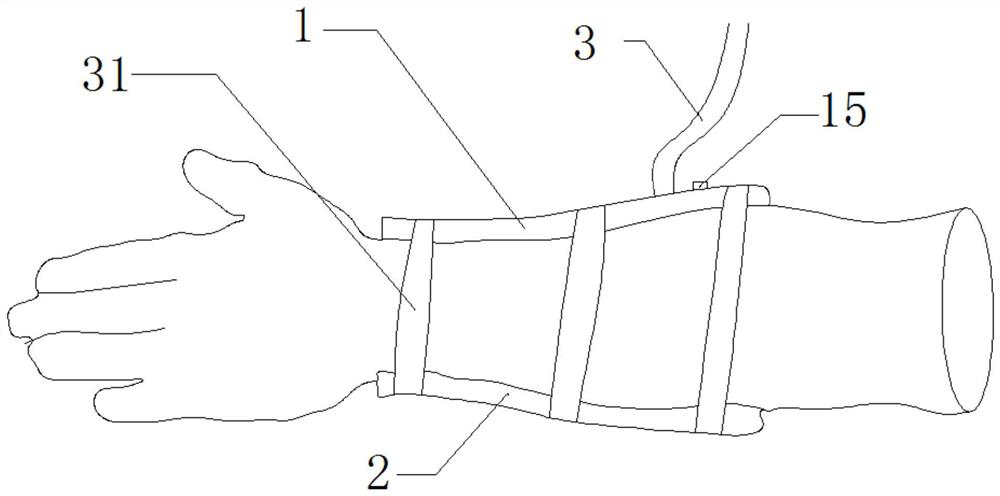

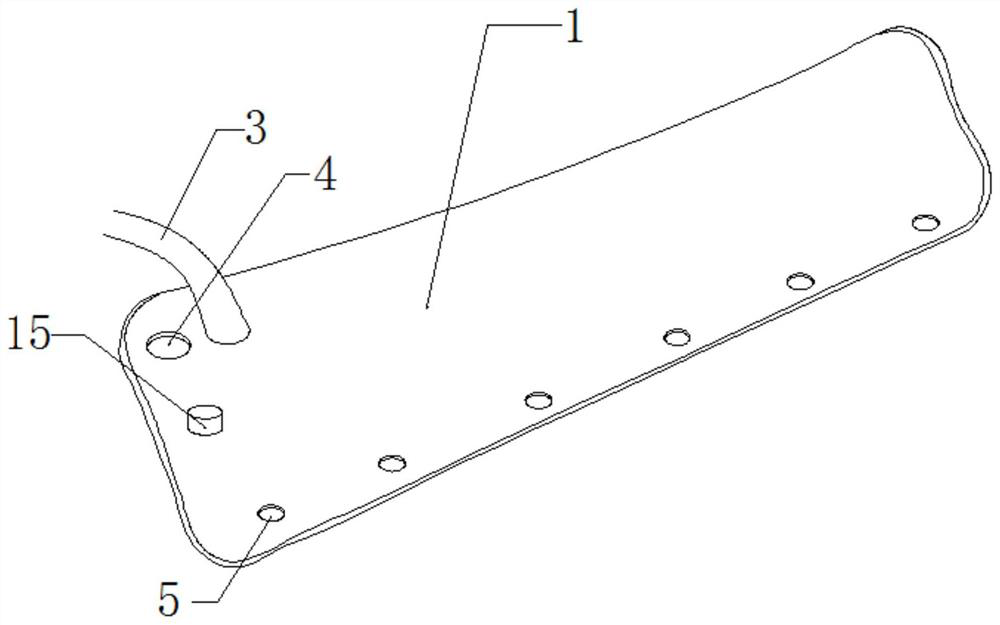

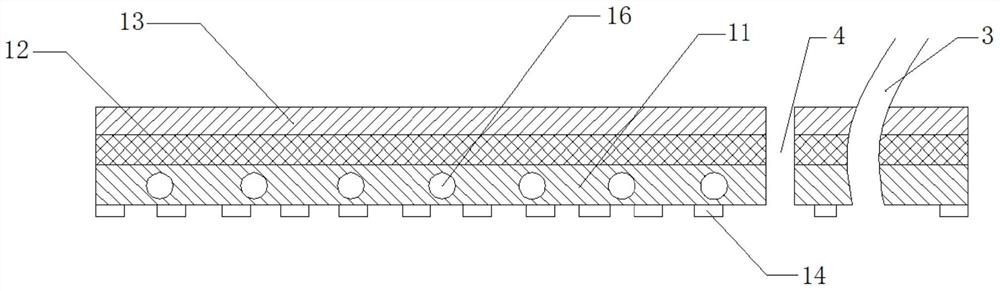

[0023] Combine below figure 1 , figure 2 , image 3 and Figure 4 The present invention will be described in detail.

[0024] A fracture splint with heat preservation function, characterized in that it includes a left splint 1, a right splint 2 and a fastening strap 31, the left splint 1 and the right splint 2 have the same structure and are symmetrical to each other, and the left splint 1 is three The layer structure includes heat storage layer 11, heating layer 12 and insulation layer 13 respectively from inside to outside. The end surface of the heat storage layer 11 facing the skin of the human body is arranged with several heat insulation strips 14 arranged in parallel and at intervals. The heating layer 12 A heating element is arranged inside, and the heating element is switched and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com