Clothespin device for garment production line

A production line and clothespin technology, applied in the field of clothing machinery, can solve the problem that the action process is not very simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

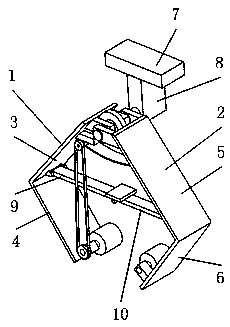

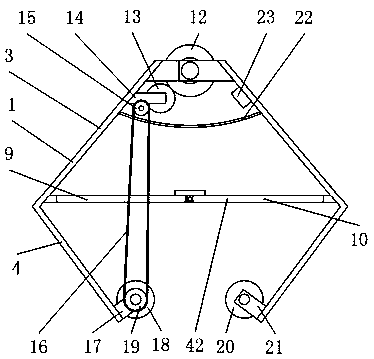

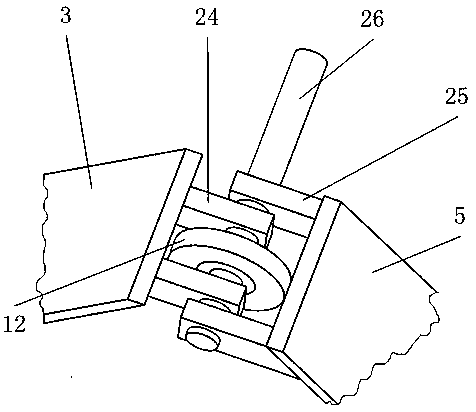

Image

Examples

specific Embodiment approach

[0066] Specific embodiments: when the clothespin device of the present invention is not clamping clothes, the first strip-shaped swing plate 9 and the second strip-shaped swing plate 10 are collinear, and now the first strip-shaped swing plate 9 and the second strip-shaped swing plate 10 constitutes a temporary straight plate, the lower surface of the weight limiting plate 34 is attached to the upper surface of the first bar-shaped pendulum plate 9 and the upper surface of the second bar-shaped pendulum plate 10 respectively, and the leaf spring 22 is in a stretched state at this time . The first elastic wheel 18 is not rotating, the scroll spring 38 is not compressed, and the second gear 13 and the first gear 12 are not engaged. The first V-shaped plate 1 and the second V-shaped plate 2 are in an open state, and there is a distance between the first elastic wheel 18 and the second elastic wheel 20 .

[0067] When the clothes peg device needs to clamp clothes, the workman onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com