Squid main body automatic peeling machine

A technology of peeling machine and main body, which is applied in the field of squid main body automatic peeling machine, can solve the problems of low efficiency of manual squid peeling, achieve the effects of improving peeling efficiency, realizing mechanized processing, and widening market space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

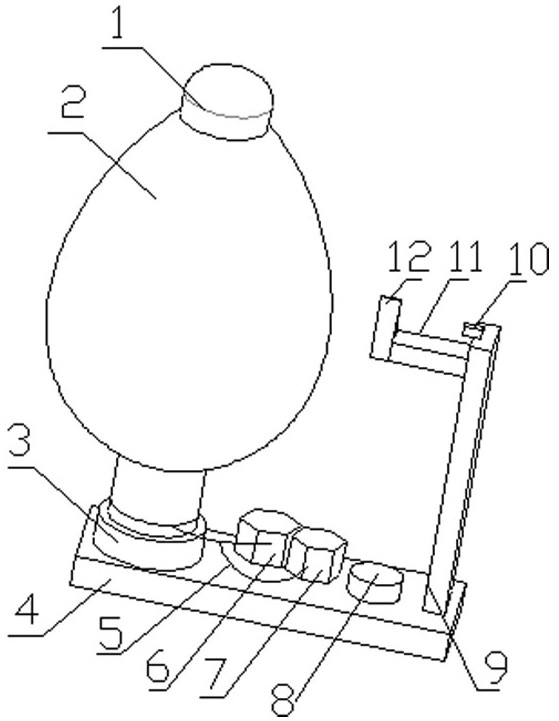

[0016] Squid main body automatic peeling machine, including hollow rotating rod 1, rubber hollow body 2, gear motor 3, base 4, pipe 5, air extractor 6, inflator 7, controller 8, first electric lifting rod 9, distance sensor 10 , the second electric lifting rod 11 and scraper, the hollow rotating rod 1 is covered with a rubber hollow body 2 to realize simultaneous rotation; the lower part of the hollow rotating rod 1 is equipped with a reduction motor 3 for providing power; the lower part of the reduction motor 3 is equipped with Base 4, on base 4, air extractor 6, inflator 7, controller 8, first electric elevating rod 9 are successively installed, and air extractor 6, inflator 7 are used for charging and deflated in rubber hollow body 2; A distance sensor 10 is installed on the top of an electric lifting rod 9, which is used to judge the distance betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com