Weeding machine with wide range of weeding

A weeding machine and range technology, which is used in harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of large space occupation, small weeding range, and difficult to replace cutting blades, so as to achieve easy replacement, large weeding range, and high efficiency. The effect of maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

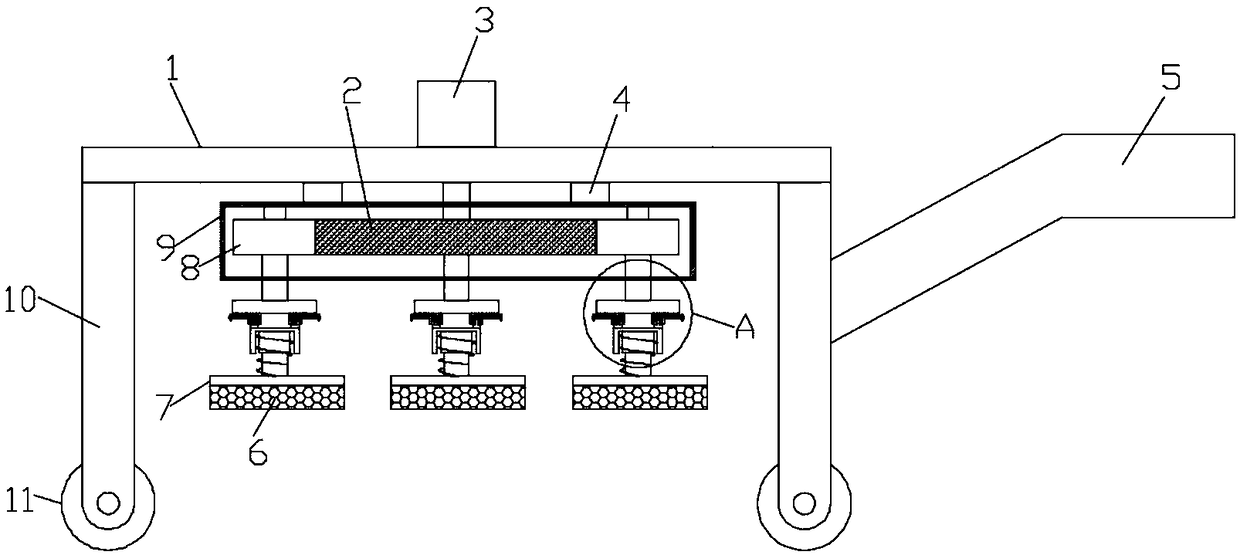

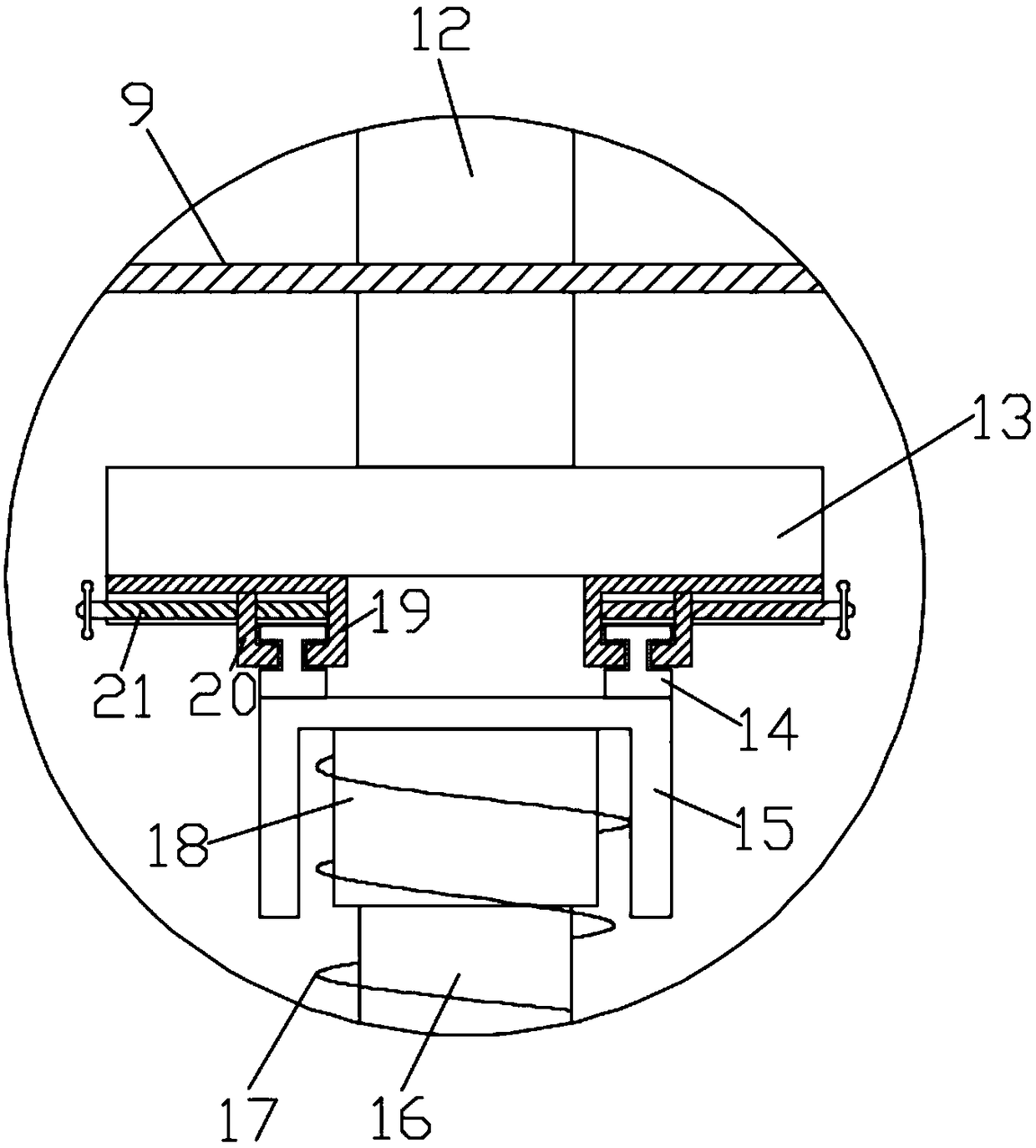

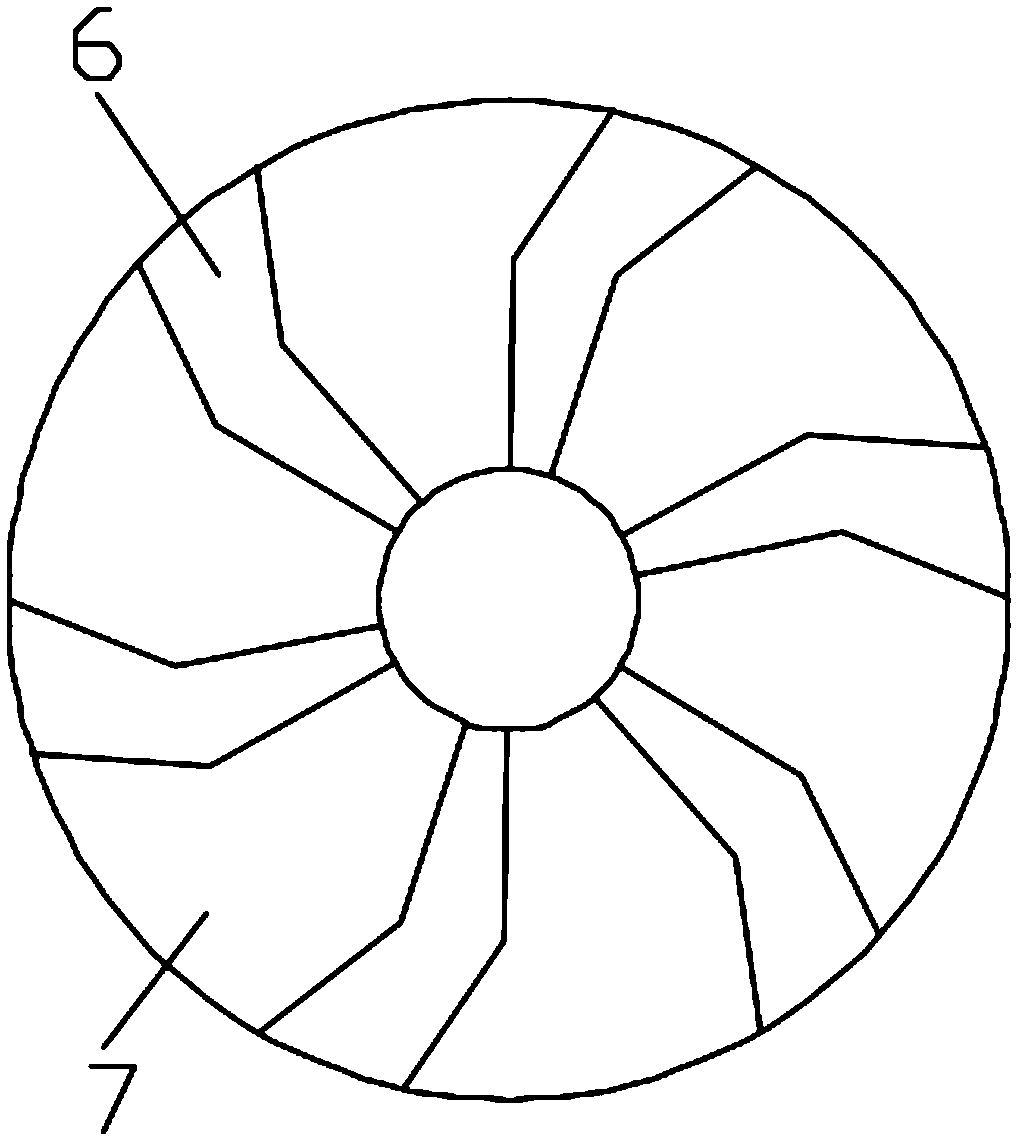

[0020] refer to Figure 1-3 , a weeding machine with a wide range of weeding, comprising a fixed base 1, the upper end of the fixed base 1 is fixedly connected with a drive motor 3, the lower end of the fixed base 1 is fixedly connected with two connecting columns 4, and the lower ends of the two connecting columns 4 are fixed together Connected with the housing 9, the output shaft of the driving motor 3 runs through the upper end of the fixed base 1 and the housing 9 in turn, and the end of the output shaft of the driving motor 3 is fixedly connected with the first gear 2. When in use, the operator turns on the switch of the driving motor, The switch of the drive motor 3, the output shaft of the drive motor 3 drives the first gear 2 to rotate, and the inner top of the housing 9 is rotatably connected with a plurality of second gears 8, and each second gear 8 is meshed with the first gear 2, The rotation of the first gear 2 drives a plurality of second gears 8 to rotate, the l...

Embodiment 2

[0023] refer to Figure 1-3 , a weeding machine with a wide range of weeding, comprising a fixed base 1, the upper end of the fixed base 1 is fixedly connected with a drive motor 3, the lower end of the fixed base 1 is fixedly connected with two connecting columns 4, and the lower ends of the two connecting columns 4 are fixed together Connected with the housing 9, the output shaft of the driving motor 3 runs through the upper end of the fixed base 1 and the housing 9 in turn, and the end of the output shaft of the driving motor 3 is fixedly connected with the first gear 2. When in use, the operator turns on the switch of the driving motor, The switch of the drive motor 3, the output shaft of the drive motor 3 drives the first gear 2 to rotate, and the inner top of the housing 9 is rotatably connected with a plurality of second gears 8, and each second gear 8 is meshed with the first gear 2, The rotation of the first gear 2 drives a plurality of second gears 8 to rotate, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com